Method for calculating radiation noise of silencer of exhaust system

A radiation noise and exhaust system technology, applied in design optimization/simulation, etc., can solve problems such as difficulty in detecting muffler radiation noise, test failure, high iteration cost, etc., and achieve the effect of saving development cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

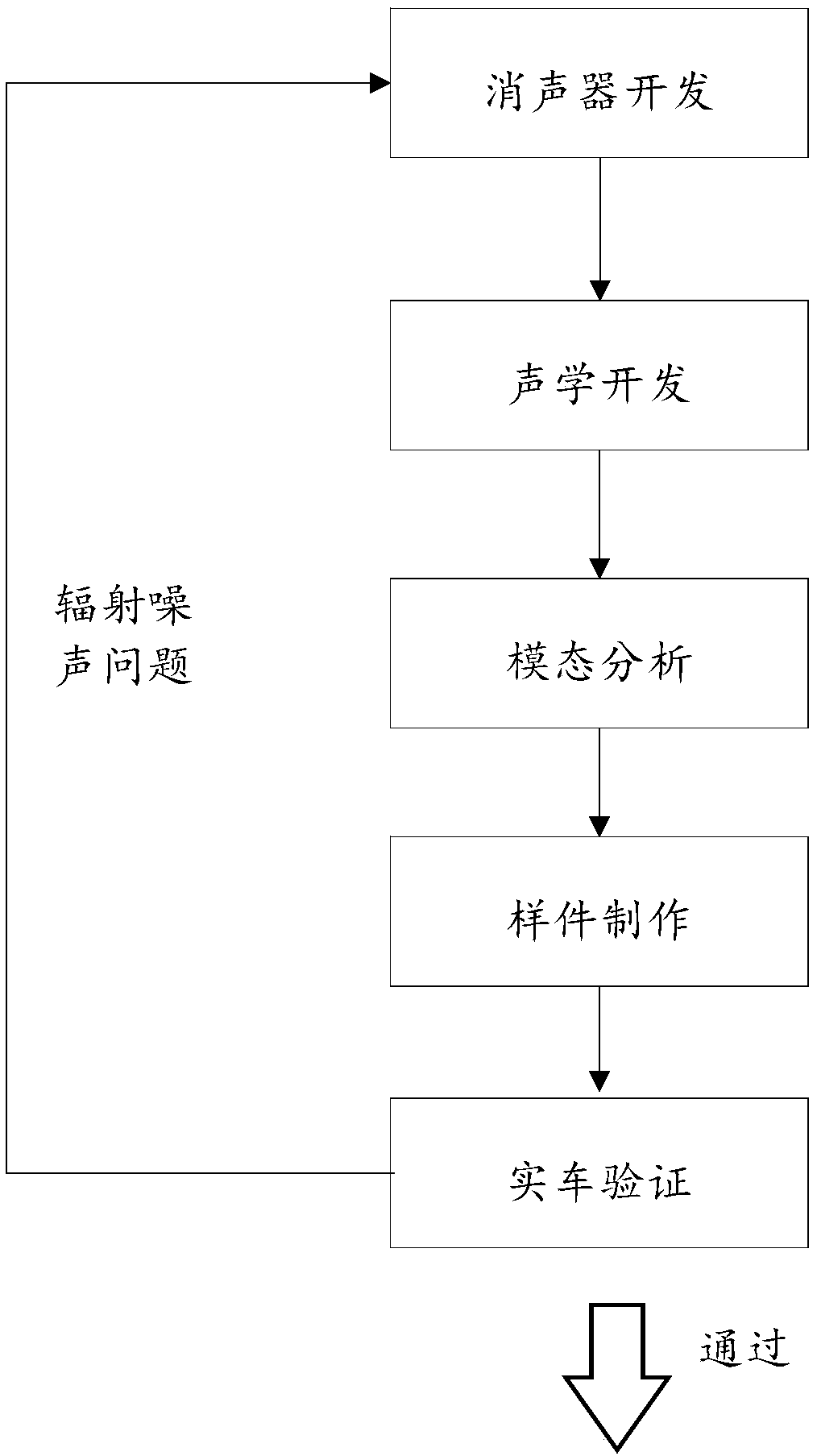

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

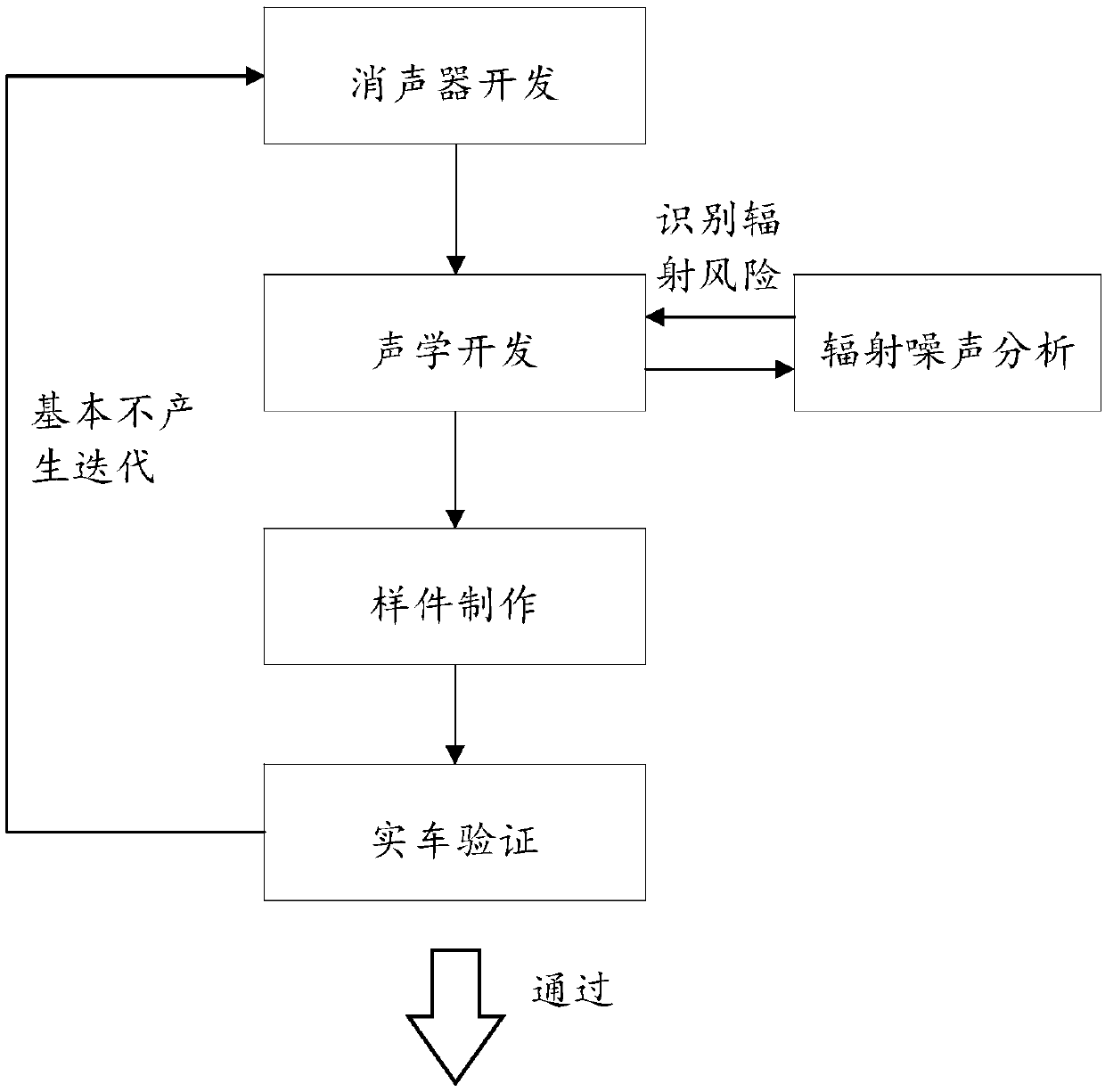

[0024] Please refer to figure 2 As shown, the present invention discloses a development process of exhaust system muffler radiated noise, which includes the steps of muffler development, acoustic development, sample production and actual vehicle verification, wherein the acoustic development includes Calculation method of radiated noise of muffler of exhaust system.

[0025] Compared with the prior art, the exhaust system muffler radiation noise development process of the present invention requires testing and structural adjustment in advance, and risk identification should be carried out in the acoustic development step of the early analysis as much as possible. By eliminating and optimizing the risk in advance through calculation, the final development result can basically eliminate the risk of repeated iterations, and the optimized structure can also obtain better radiation noise performance.

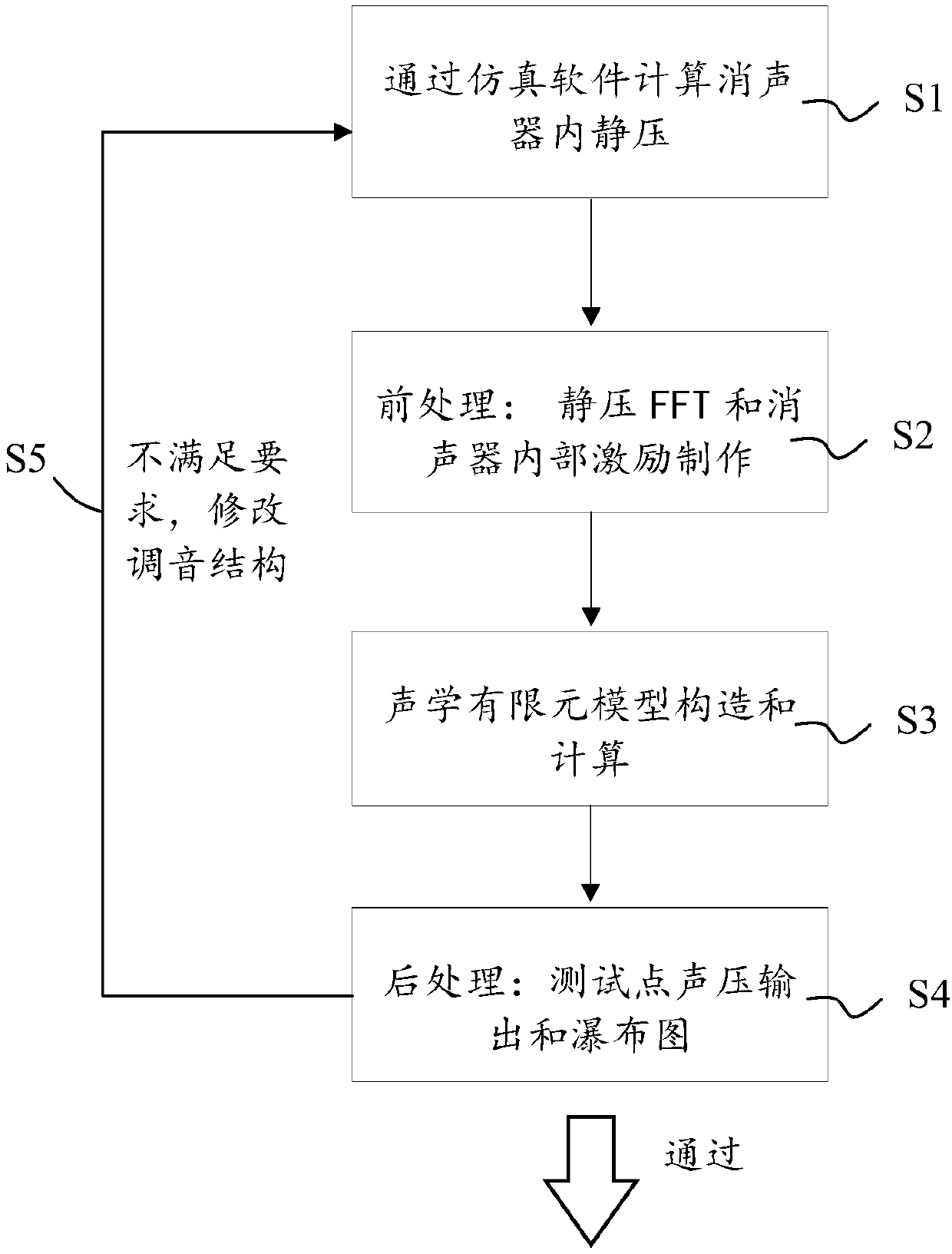

[0026] Please refer to image 3 As shown, the exhaust system muffler radiatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com