Multi-angle fabric gloss performance measuring system and method

A measuring system, multi-angle technology, applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problem of not being able to correctly reflect consumers' perception of fabric luster, and achieve the effect close to the visual perception.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

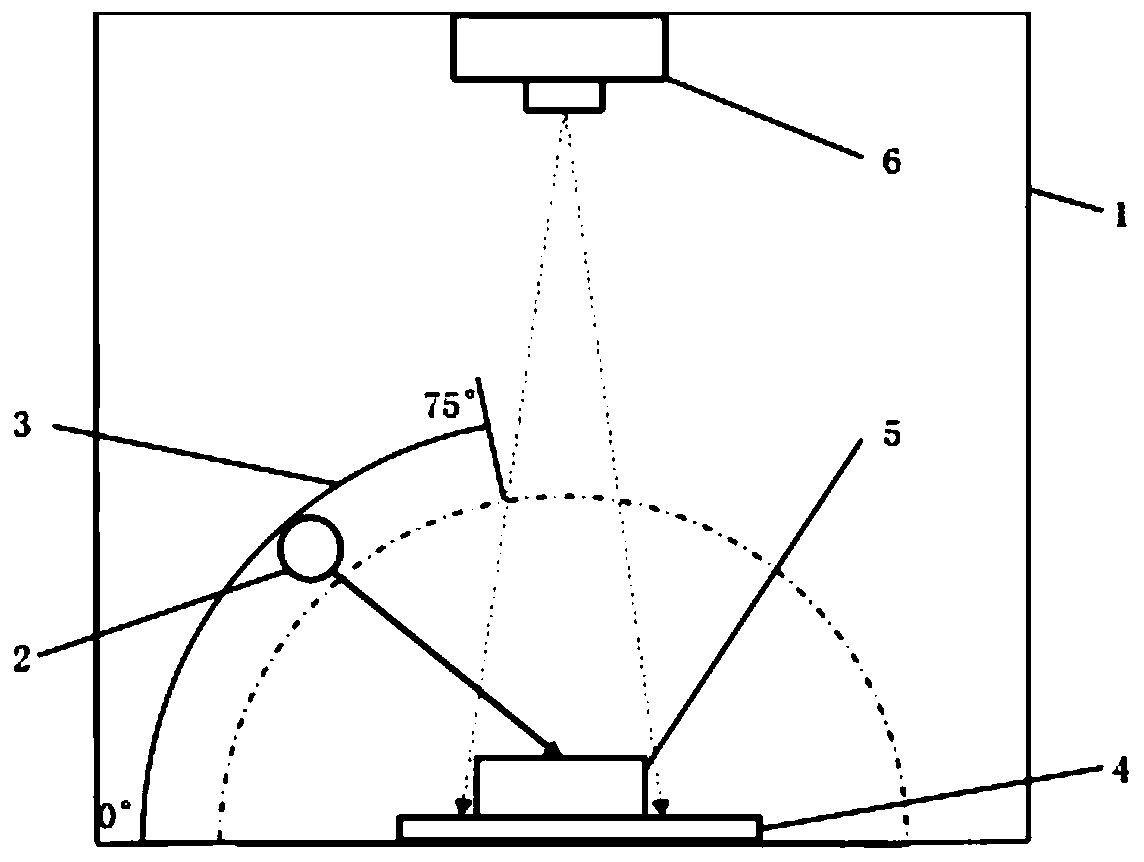

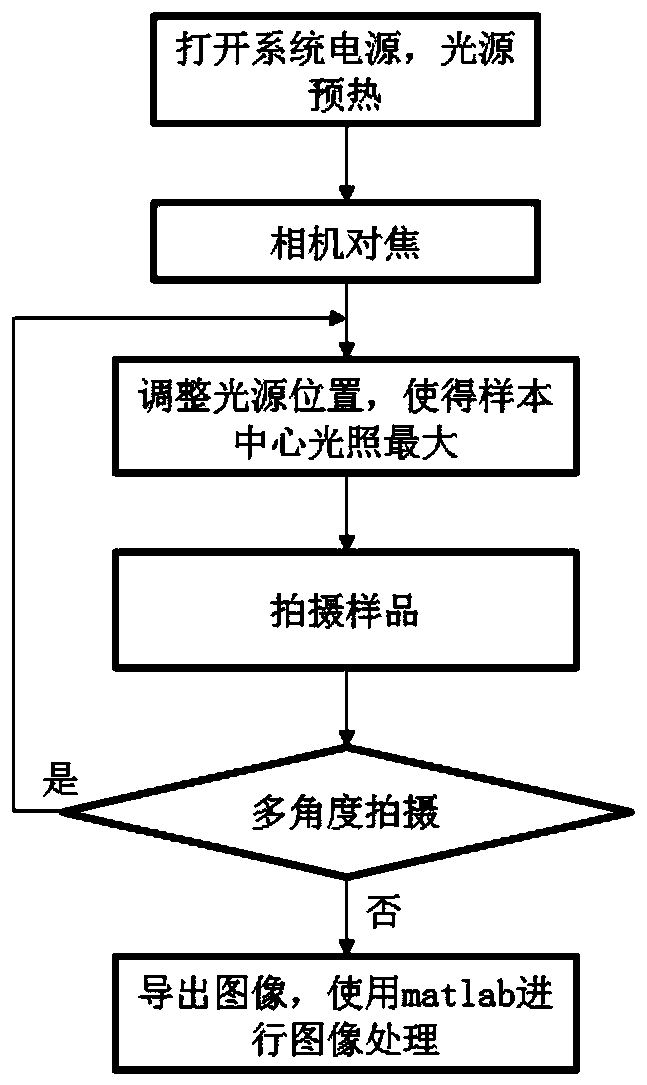

[0026] refer to figure 1 and figure 2 The embodiment of a multi-angle fabric gloss property measuring system and method of the present invention will be further described.

[0027] Such as figure 1 As shown, an embodiment of the present invention provides a multi-angle fabric gloss performance measurement system, including a black room 1, the black room 1 is a whole body black box, used to isolate the interference of external light sources on the sample measurement, in the black room 1 The main parts of the system are respectively a camera module 6 , a parallel collection light source illumination module 2 and an object stage 4 . In this embodiment, the camera module 6 may be a color CCD camera. The color CCD camera 6 is arranged on the top of the black room 1, and the color CCD camera is arranged towards the stage 4 in the black room 1, and the angle changing device 3 is located on the parallel collection light source illumination module 2 for passing through different po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com