Waste incineration system

A technology of waste incineration and waste incinerator, which is applied in the directions of incinerator, combustion method, combustion type, etc., can solve the problem of only supplying gas from the center of the furnace, reduce gas consumption, prevent the generation of harmful gas, and reduce the installation area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

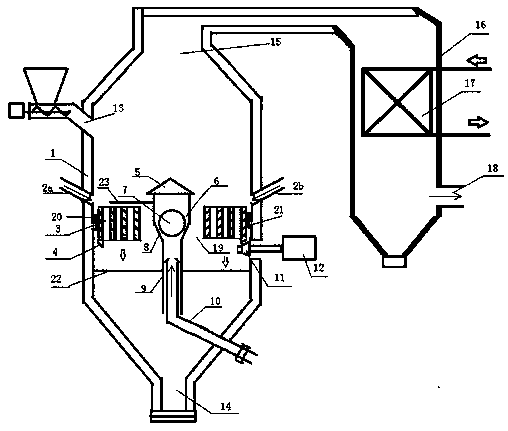

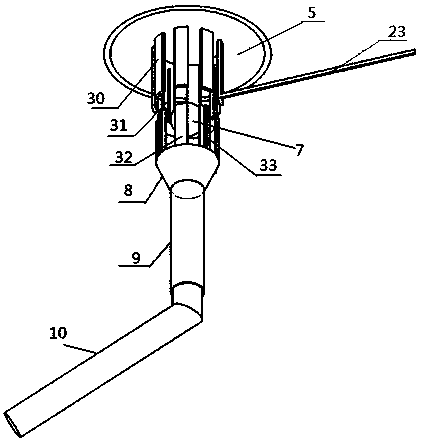

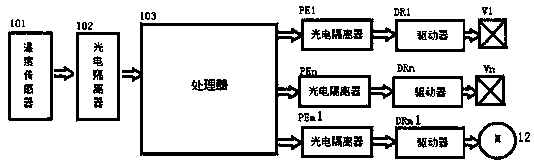

[0026] figure 1 It is a schematic diagram of the composition of the waste incineration system provided by the first embodiment of the present invention, figure 2 It is a three-dimensional structural diagram of some parts of the air supply device of the waste incineration system provided by the first embodiment of the present invention, as shown in Figure 1-2 As shown, the waste incineration system includes a waste incinerator and a waste heat boiler 16, wherein the waste heat boiler 16 uses the flue gas produced by the waste incinerator to heat water. The waste incinerator includes a shell 1 and an air supply device, and also includes a 1 The internal rotary bed 3, the center of the rotary bed 3 is provided with a through hole 19 along the axial direction, the periphery of the rotary bed 3 deviated from the center is provided with a plurality of ash leakage holes radially in the axial direction, and the rotation center of the rotary bed 3 is vertically Orientation set to ro...

no. 2 example

[0041] Figure 4 It is a schematic diagram of the composition of the garbage incinerator provided by the second embodiment of the present invention, such as Figure 4 As shown, the structure of the garbage incinerator provided by the second embodiment of the present invention is basically the same as that of the garbage incinerator provided by the first embodiment of the present invention. The filtering mechanism includes a partition 25 which is perpendicular to the axis of the casing and tightly combined with the inner wall of the casing. A smoke through hole 25 is arranged in the center of the partition 25 in the axial direction, and a smoke exhaust cap 26 is arranged on the through hole 25 . Because the present invention is equipped with a filter mechanism, the dust rolled up due to the swirling flow formed by the air supply device in the incineration chamber falls back into the incineration chamber, so that the inner chamber of the waste heat boiler and the heat exchanger ...

no. 3 example

[0043] Figure 5 It is a schematic diagram of the composition of the garbage incinerator provided by the fourth embodiment of the present invention, such as Figure 5 As shown, the structure of the garbage incinerator provided by the third embodiment of the present invention is basically the same as that of the garbage incinerator provided by the second embodiment of the present invention, the only difference is that the garbage incinerator also includes a motor 29, and the output of the motor 29 The shaft is connected to the conical wheel 28 through a reduction mechanism; an annular cone ring 27 is arranged along the circumference of the incinerator shell, and a plurality of gas supply pipes, such as gas supply pipe 2a and gas supply pipe 2b, are fixed on the annular cone ring 27 by a fixing mechanism. The conical wheel 28 meshes with the conical gear ring 27. When the motor 29 is working, the included angle between the gas supply pipe 2a, the gas supply pipe 2b and the tange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com