Vehicle microactuator applied to refueling tank cover or charging box cover of vehicle

A charging box and actuator technology, applied in the field of auto parts, can solve the problems of large interaction force between the lock pin and the rotary push rod, motor failure, increased wear and tear of parts, etc., so as to delay and prevent water vapor from entering the motor cavity. The effect of reducing the risk of wear and fracture, reducing the risk of water ingress rust damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

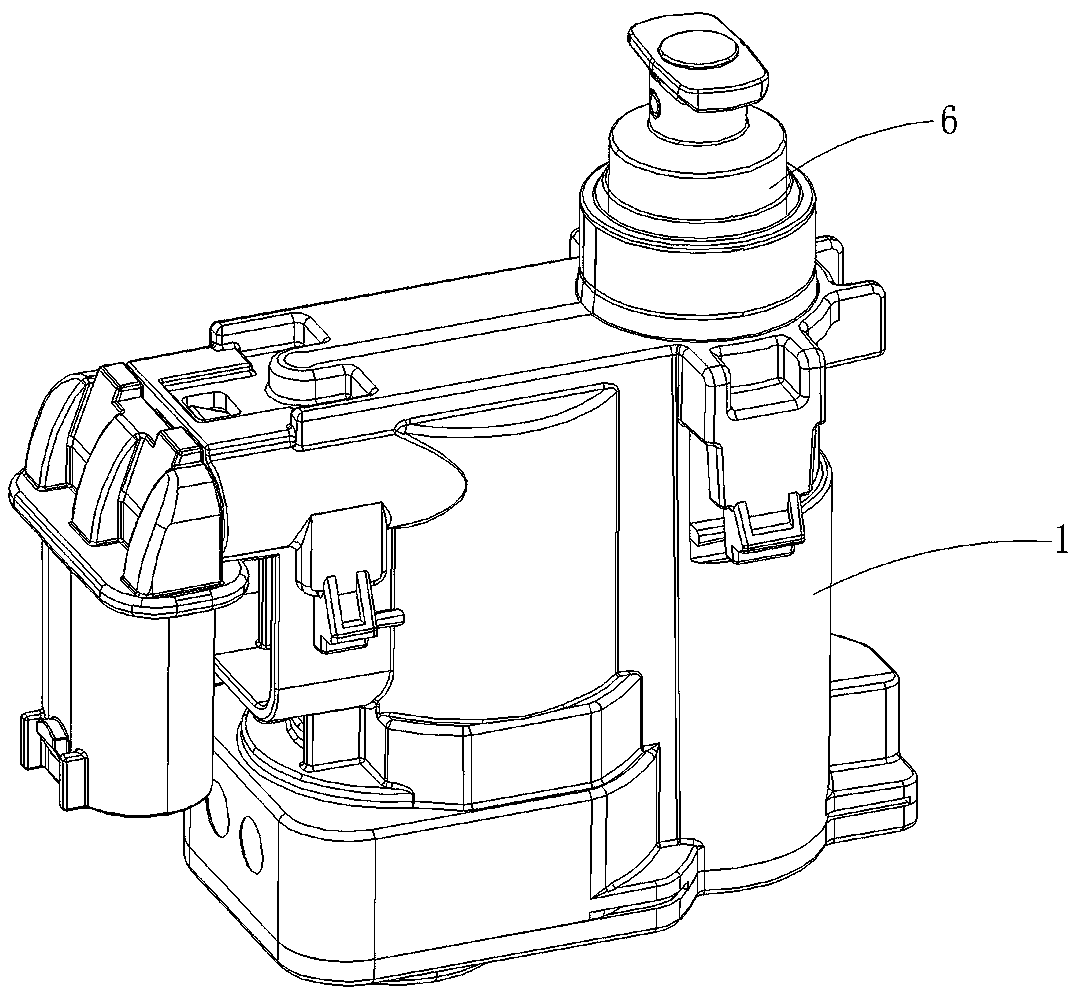

[0043] refer to Figure 1 to Figure 13 , a vehicle micro-actuator applied to the fuel tank cover or charging box cover of an automobile, comprising a housing 1, the housing 1 is divided into a motor cavity 2 and a locking cavity 3, and the motor cavity 2 is provided with An electric locking assembly, the electric locking assembly includes a motor 4, a transmission assembly and a locking member 5 from top to bottom, the motor 4 communicates with the vehicle electronic control system, and the locking chamber 3 A manual locking assembly is provided, and the manual locking assembly includes a rotary push rod 6, a drive sleeve 7 and a rotary sleeve 8 from top to bottom, and the rotary push rod 6 is connected to the car cover in transmission, and the The electric locking assembly can lock the manual locking assembly, and the locking member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com