Construction method for suspension bridge gravity type anchorage porous annular foundations

A gravity type, suspension bridge technology, which is applied to the construction field of the gravity type anchorage porous annular foundation of suspension bridges, can solve the problems of increased construction cost of well body concrete, large quantity of well body concrete, difficult soil removal, etc., and achieves the safety of subsidence. It has the effect of guaranteeing, accelerating the construction progress and smoothness, reducing the construction period and economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is further described:

[0019] As shown in the accompanying drawings, a construction method of a suspension bridge gravity anchorage porous annular foundation of the present invention comprises the following steps:

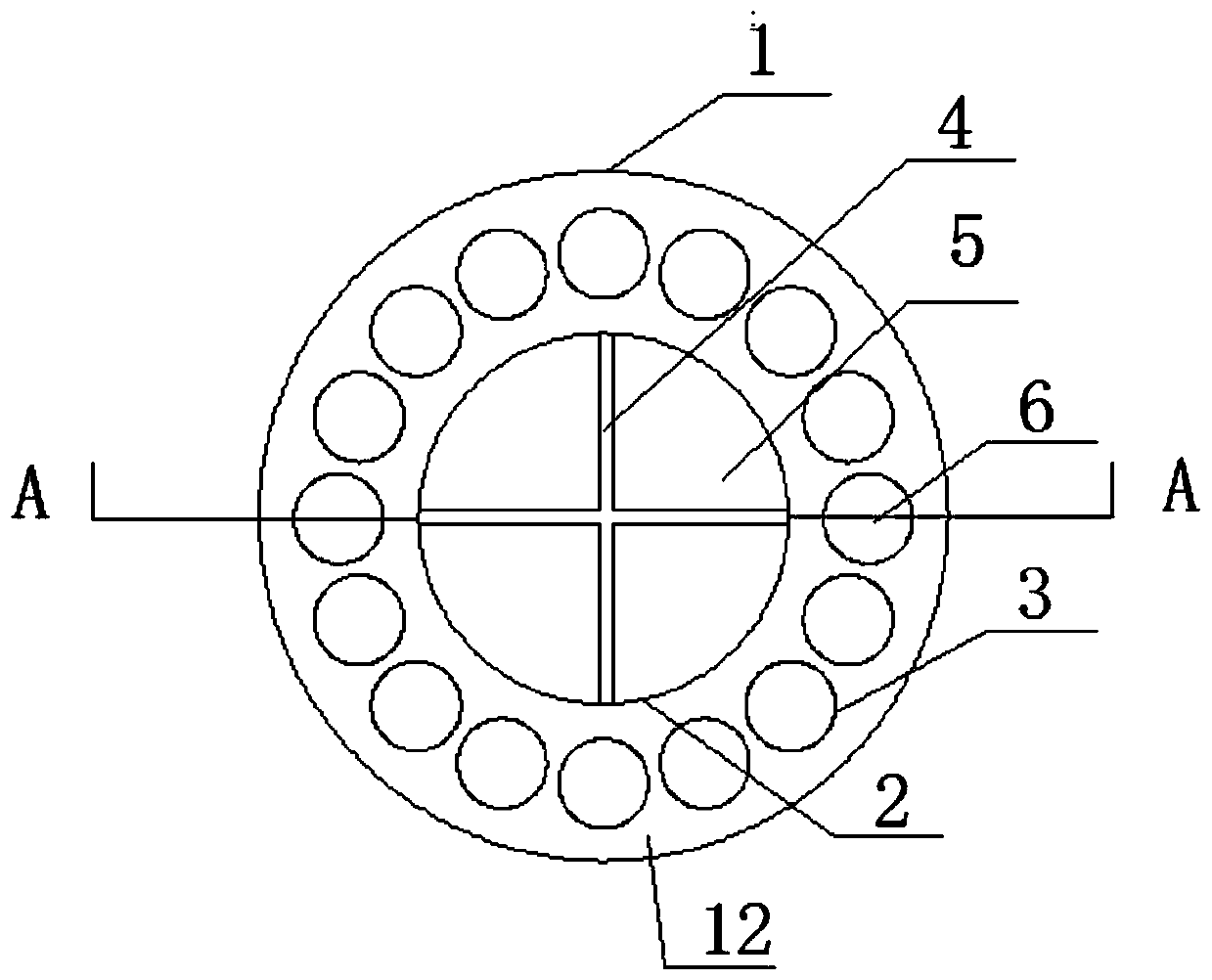

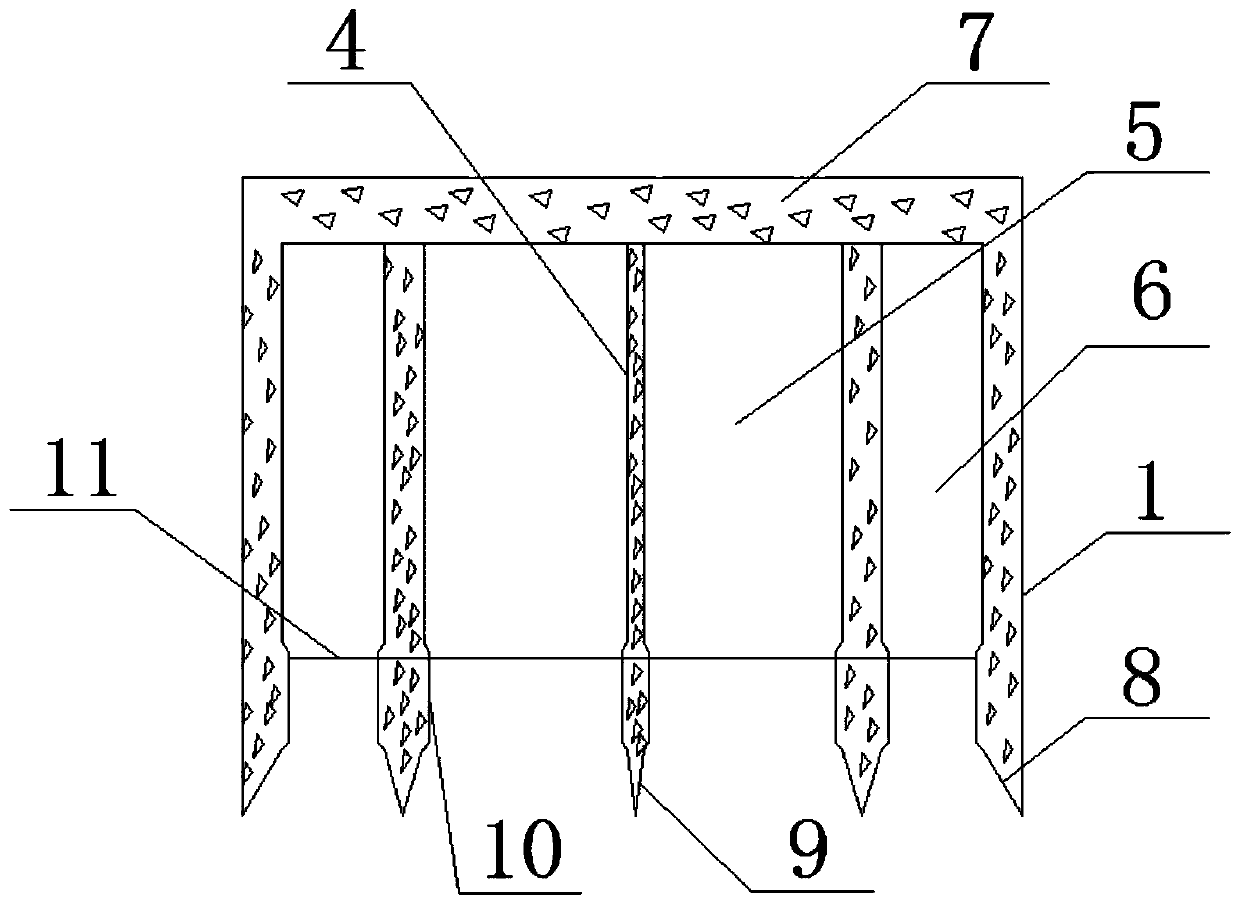

[0020] The first step is to prefabricate a plurality of annular foundations, each of which includes an annular cylindrical inner wall 2, and an annular cylindrical outer wall 1 is sleeved outside the annular cylindrical inner wall. The inner wall and the outer wall The annular area between the inner and outer walls is filled with concrete and pre-embedded with rebars. A plurality of vertical steel pipes 3 are installed as wells 6 at uniform intervals along the circumferential direction of the annular area between the inner wall and the outer wall. A cross-shaped partition wall 4 is fixed in the cavity to divide the cavity of the inner wall into four fan-shaped areas 5 on average; The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com