Frame type bank revetment protection slope prefabricated block body and using method thereof

A prefabricated block and frame-type technology, applied in the fields of botany equipment and methods, coastline protection, container cultivation, etc., can solve the problems of difficult survival of green plants, unbalanced structural stress, waste of materials, etc., to ensure water permeability, guarantee Hollow rate, the effect of reducing the weight of the block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

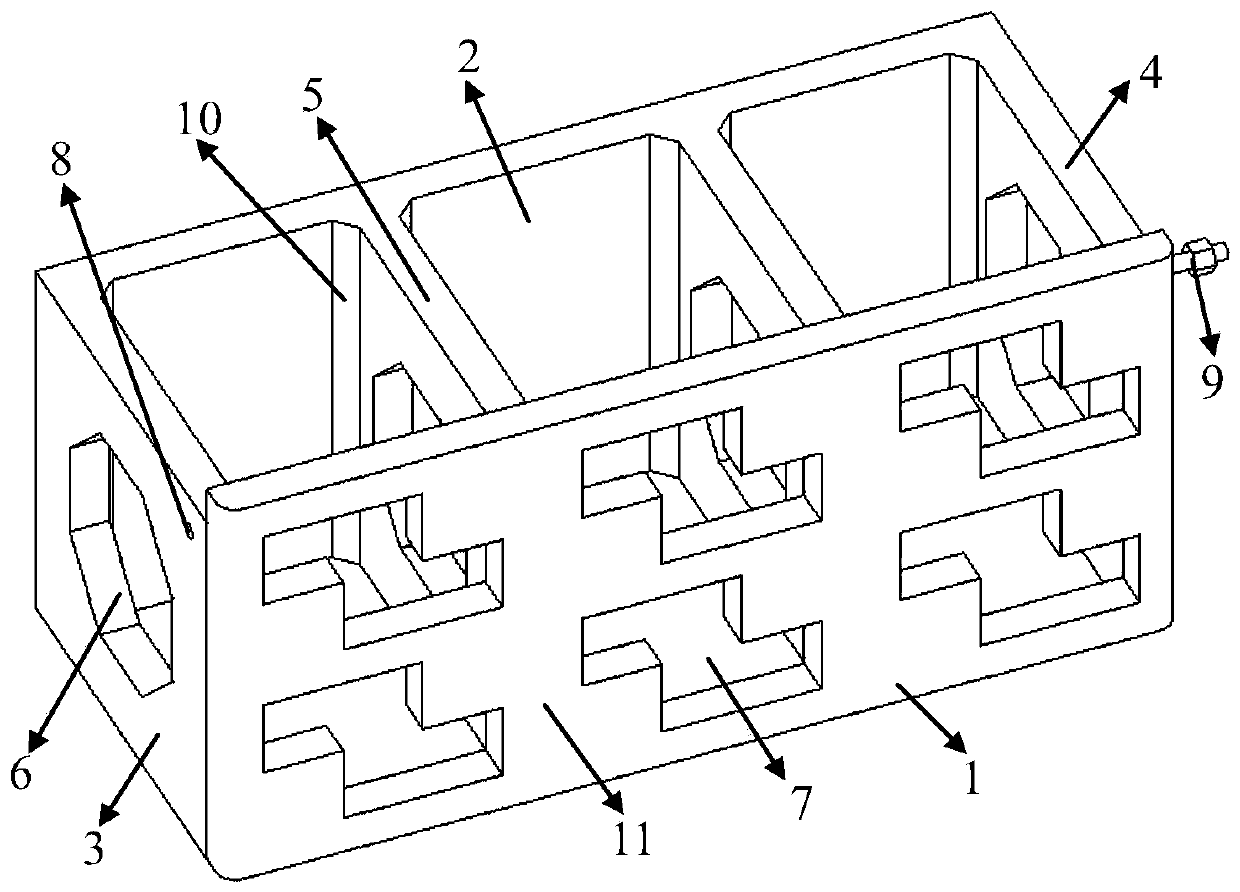

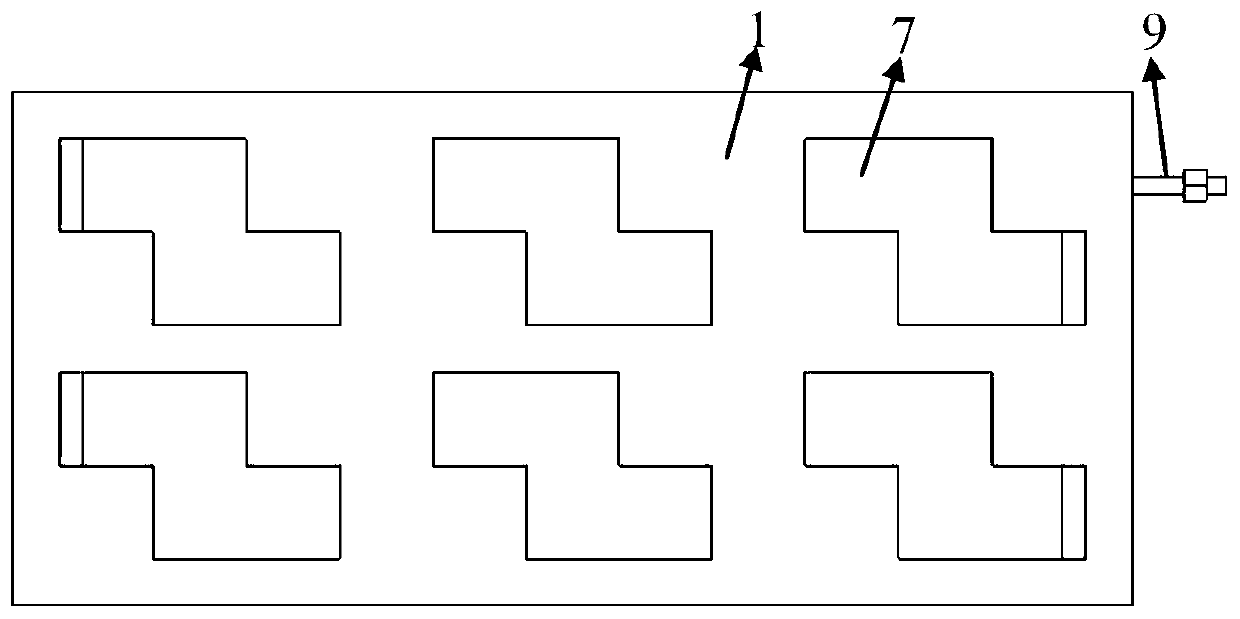

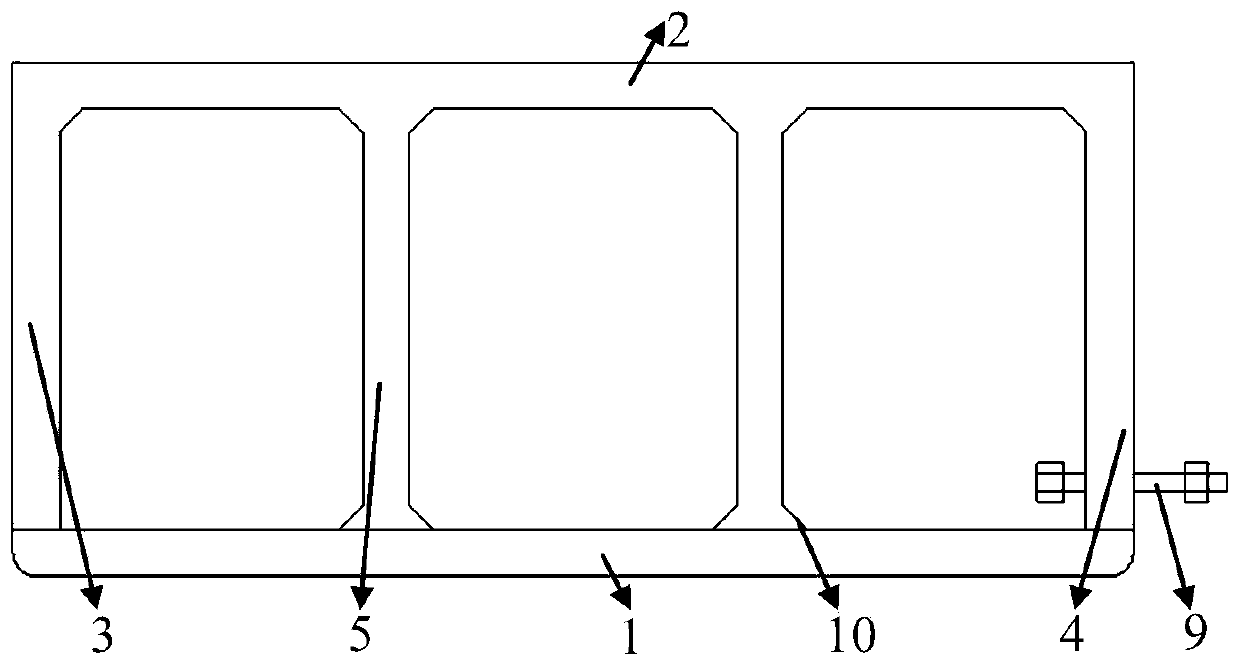

specific Embodiment 1

[0072] The length of the block is 1200mm, the width is 550mm, the height of the panel 1 is 550mm, and the thickness is 50mm, the height of the backplane 2 is 500mm, and the thickness is 50mm, the first outer frame 3, the second outer frame 4, and the inner frame 5 The thickness is 50mm, the side length of the square hole 14 of the circulation hole 7 is 100mm, the hole 6 is a regular octagon, the radius of the inscribed circle of the hole 6 of the first outer frame 3 and the second outer frame 4 is 150mm, and the hole of the inner frame 5 6 The radius of the inscribed circle is 137.5 mm, and the top of the hole 6 of the inner frame 5 is 12.5 mm lower than the top of the hole 6 of the first outer frame 3 and the second outer frame 4. The number of inner frames 5 is 2, and the number of circulation holes 7 in the two-layer hollow groups is 3.

[0073] Hollow rate on panel 1 = hollow area / area of panel 1 = (100×100×4×6) / (1200×550)=36.36%.

[0074] Several blocks are sequentiall...

specific Embodiment 2

[0085] The length of the block is 2400mm, the width is 1100mm, the height of the panel 1 is 1100mm, and the thickness is 100mm, the height of the backplane 2 is 1000mm, and the thickness is 100mm, the first outer frame 3, the second outer frame 4, and the inner frame 5 The thickness is 100mm, the side length of the square hole 14 of the circulation hole 7 is 200mm, the hole 6 is a regular octagon, the radius of the inscribed circle of the hole 6 of the first outer frame 3 and the second outer frame 4 is 300mm, and the hole of the inner frame 5 6. The radius of the inscribed circle is 275 mm, and the top of the hole 6 of the inner frame 5 is 25 mm lower than the top of the hole 6 of the first outer frame 3 and the second outer frame 4. The number of inner frames 5 is 2, and the number of circulation holes 7 in the two-layer hollow groups is 3.

[0086] Hollowout rate on panel 1=hollowout area / area of panel 1=(200×200×4×6) / (2400×1100)=36.36%.

[0087] Several blocks are seque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com