Biodegradable lubricating oil and preparation process thereof

A biodegradable and lubricating oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as environmental, soil and water pollution, easy corrosion, and damage to the ecological environment, and achieve uniform anti-corrosion performance, uniform anti-corrosion performance, Solve the effect of uneven dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The concrete preparation process of modified vegetable oil is as follows:

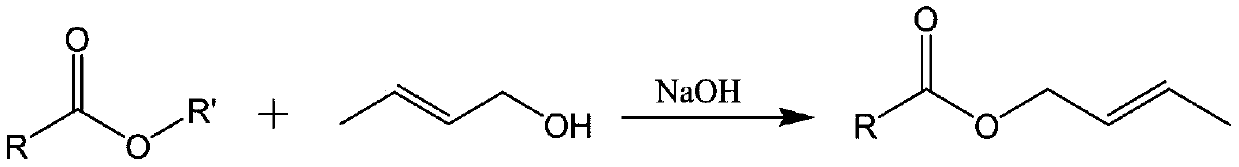

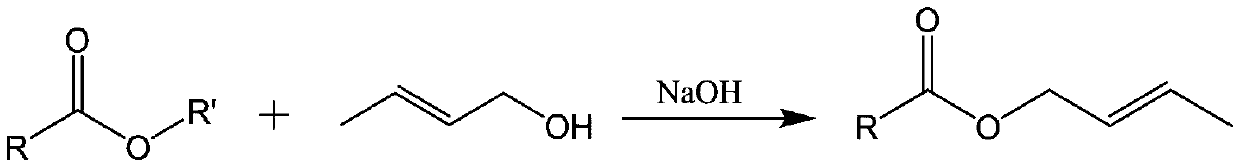

[0023] Step 1, mix cottonseed oil, soybean oil and castor oil according to the mass ratio of 1:2.1:0.8 to obtain mixed oil, add 1kg of mixed oil into the reaction kettle and raise the temperature to 60-65°C, then oxidize 13g of hydrogen Add sodium into 240g of crotyl alcohol, stir and mix evenly, then add it to the reaction kettle, keep the temperature constant and stir for 4-5h, after the product is layered, the upper oil layer is washed until neutral and then dried to obtain pretreated vegetable oil. The reaction structure is as follows;

[0024]

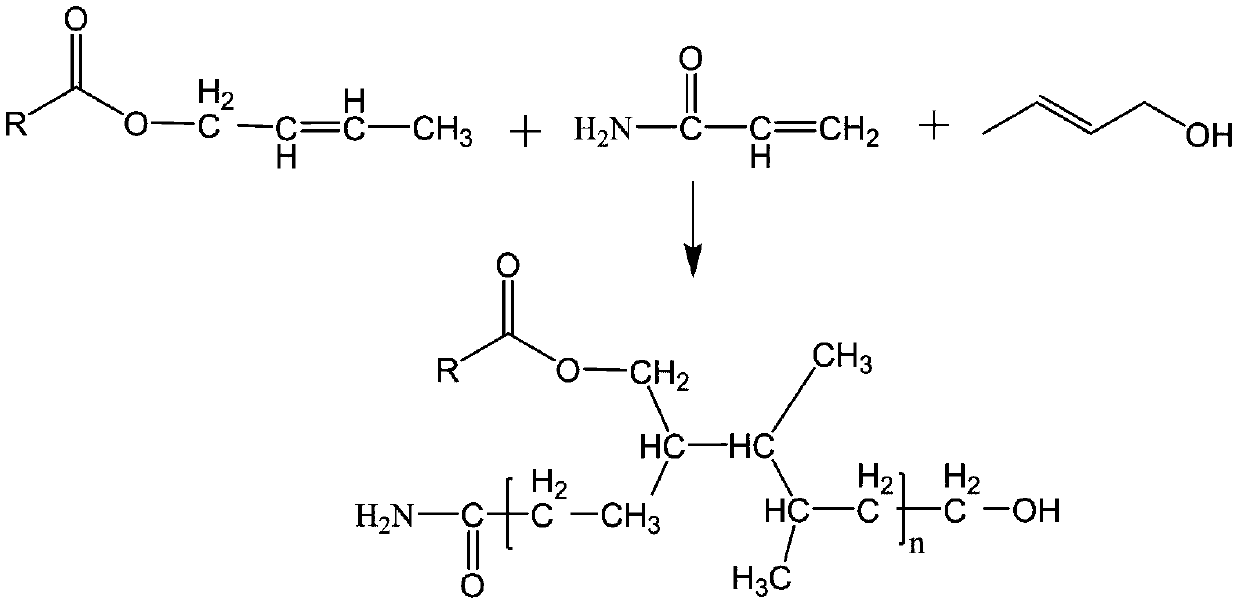

[0025] Step 2, weigh a certain amount of acrylamide and dissolve it in ethanol, configure it as an acrylamide solution with a mass concentration of 60%, add 1 kg of the pretreated vegetable oil prepared in step 1 into the reaction kettle, and then continuously pass through the reaction kettle Into nitrogen for 30 minutes, then add 120g of benzoy...

Embodiment 2

[0028] The concrete preparation process of modified vegetable oil is as follows:

[0029] Step 1, mix cottonseed oil, soybean oil and castor oil according to the mass ratio of 1:2.1:0.8 to obtain mixed oil, add 1kg of mixed oil into the reaction kettle and raise the temperature to 60-65°C, then oxidize 13g of hydrogen Sodium was added to 240 g of crotyl alcohol, stirred and mixed evenly, then added to the reaction kettle, kept at a constant temperature, stirred and reacted for 4-5 hours, after the product was layered, the upper oil layer was washed until neutral and then dried to obtain pretreated vegetable oil;

[0030] Step 2, weigh a certain amount of acrylamide and dissolve it in ethanol, configure it as an acrylamide solution with a mass concentration of 60%, add 1 kg of the pretreated vegetable oil prepared in step 1 into the reaction kettle, and then continuously pass through the reaction kettle Inject nitrogen gas for 30 minutes, then add 73g of benzoyl peroxide to it,...

Embodiment 3

[0032] The concrete preparation process of modified vegetable oil is as follows:

[0033] Step 1, mix cottonseed oil, soybean oil and castor oil according to the mass ratio of 1:2.1:0.8 to obtain mixed oil, add 1kg of mixed oil into the reaction kettle and raise the temperature to 60-65°C, then oxidize 13g of hydrogen Sodium was added to 240 g of crotyl alcohol, stirred and mixed evenly, then added to the reaction kettle, kept at a constant temperature, stirred and reacted for 4-5 hours, after the product was layered, the upper oil layer was washed until neutral and then dried to obtain pretreated vegetable oil;

[0034]Step 2, weigh a certain amount of acrylamide and dissolve it in ethanol, configure it as an acrylamide solution with a mass concentration of 60%, add 1 kg of the pretreated vegetable oil prepared in step 1 into the reaction kettle, and then continuously pass through the reaction kettle Into nitrogen for 30 minutes, then add 81g of benzoyl peroxide to it, raise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com