A kind of non-slip negative film and its production and preparation mechanism

A technology for a negative film and a stirring mechanism, which is applied to shoe soles, other household appliances, clothing, etc., can solve the problems of inconvenient and quick removal of negative films, cumbersome production and processing steps, and poor rubber anti-skid performance, so as to improve production efficiency and product quality. , Reduce the steps of production and processing, and facilitate the effect of casting and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

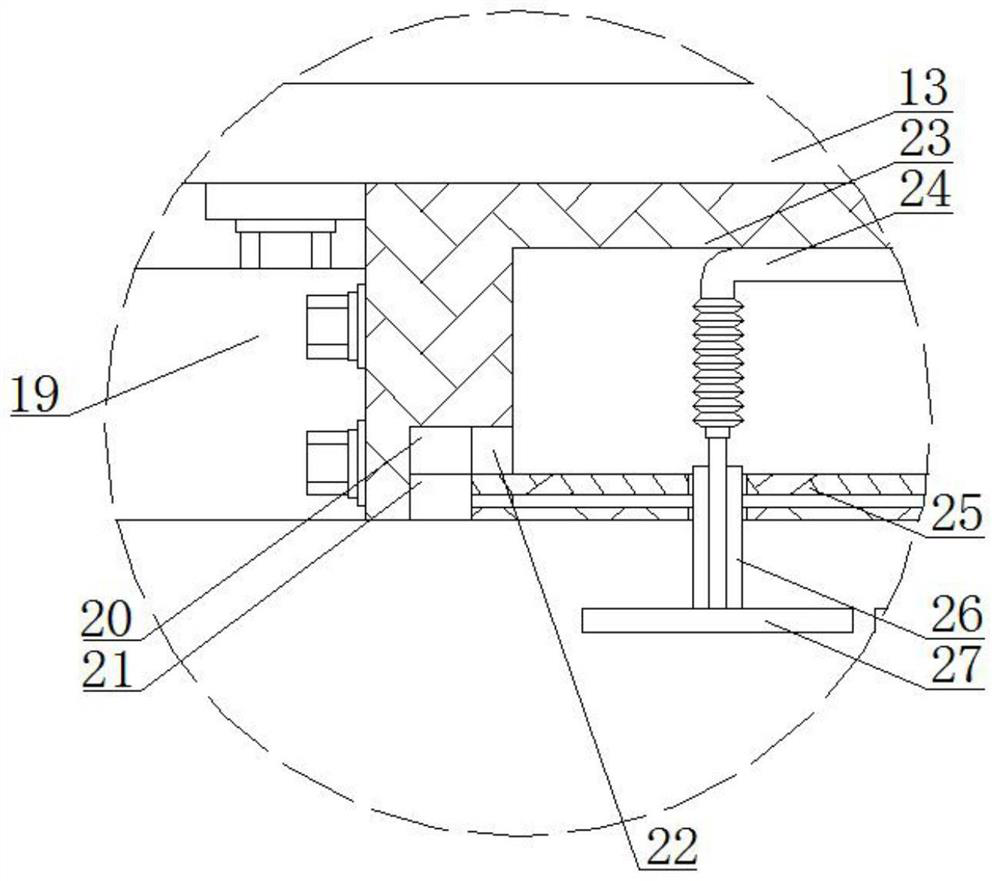

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0029] refer to Figure 1-6 , a kind of non-slip film, its raw material composition and its weight ratio are: aluminum oxide: 0.5-1.0%, calcium carbonate: 1.5-3.0%, silicon dioxide: 8-10%, sodium dimethyl dithiocarbamate: 0.5-1.0%, stearic acid: 1-2%, zinc oxide: 0.8-1.5%, sulfur: 1.5-3%, carbon black: 3-5%, nitrile rubber: 73.5-83.2%, through a variety of raw materials The mixture can effectively improve the quality of the product and replace pure rubber products, thereby helping to improve the quality of the final product and effectively improve the coefficient of static friction of the finished product to achieve:

[0030] The coefficient of static friction when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com