Flexible curved-surface foaming structure and paving and covering method thereof

A technology of foam structure and curved surface structure, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of high labor cost, time-consuming and laborious, low work efficiency, etc., to improve stability and adaptability, and reduce production costs. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

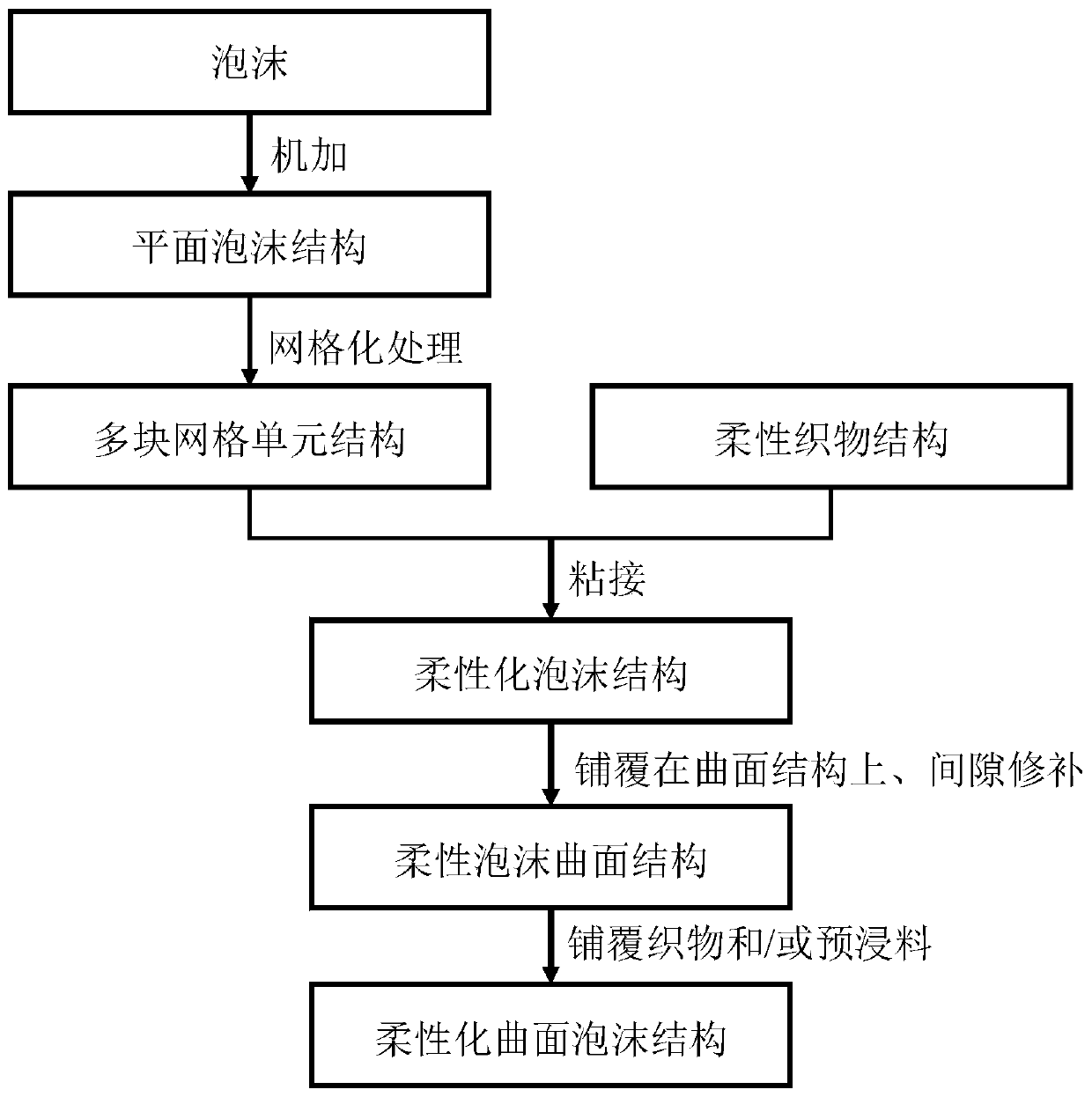

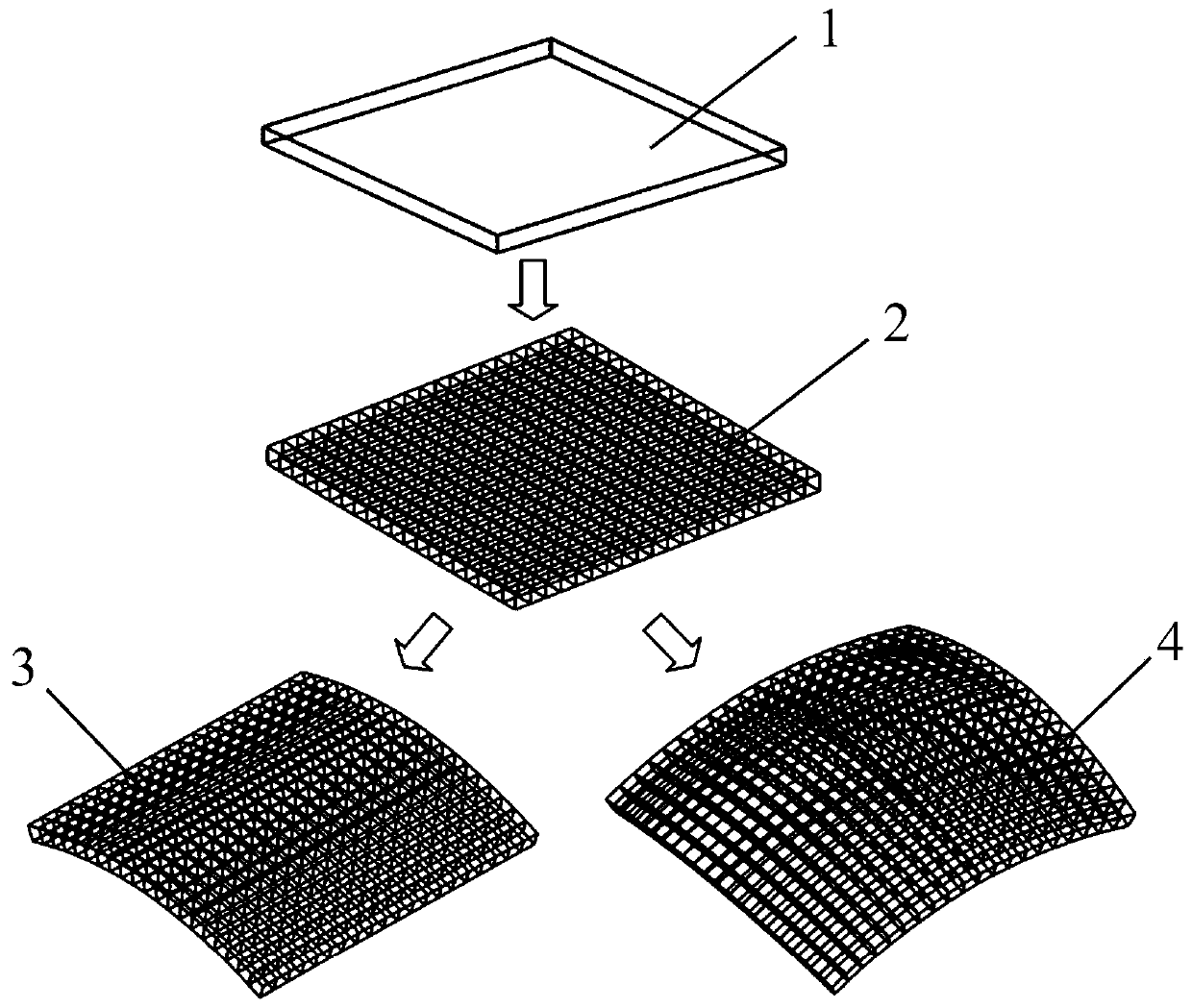

[0047] ①Adopt PMI foam core material (polymethacrylimide foam core material) to machine add planar foam structure.

[0048] ② Carry out grid processing on the planar foam structure obtained in step ①, and determine the minimum size of the unit. The minimum size is preferably a single piece of foam placed on a curved surface with high stability, and the planar foam structure is transformed into a multi-unit by cutting Block grid cell structure.

[0049] ③ bonding the multi-grid unit structure obtained in step ② to the flexible fabric structure (plain carbon cloth) through glue to obtain a flexible foam structure with bonding conditions.

[0050] 4. the flexible foam structure obtained in step 3. is covered on the curved surface structure (spherical curved surface structure) of the mould, by utilizing the self flexibility of the flexible fabric structure and the flexibility of the segmented foam structure to obtain a flexible foam curved surface structure; Among them, the flexi...

Embodiment 2

[0055] Using the same covering method and molding method as in Example 1, obtain 100 foam sandwich structures with spherical curved surfaces in Example 1, and carry out product qualification for these 100 foam sandwich structure products with spherical curved surfaces in this embodiment The qualified rate of this batch of products reached 100%.

Embodiment 3

[0057] Using the traditional overall curved surface foam sandwich structure overlay molding method to obtain 100 foam sandwich structures with the same shape and characteristics as in Example 1, these 100 foam sandwich structures with spherical surfaces in this embodiment are carried out. Product pass rate inspection, the pass rate of this batch of products is 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com