Hot melting machine system and method thereof

A technology of hot-melt machine and hot-melt head, which is applied to other home appliances, household components, home appliances, etc. It can solve the problems that the hot-melt head cannot effectively concentrate the hot-melt point temperature and the hot-melt effect is not good, so as to achieve long service life , hot-melt precision stability, high thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

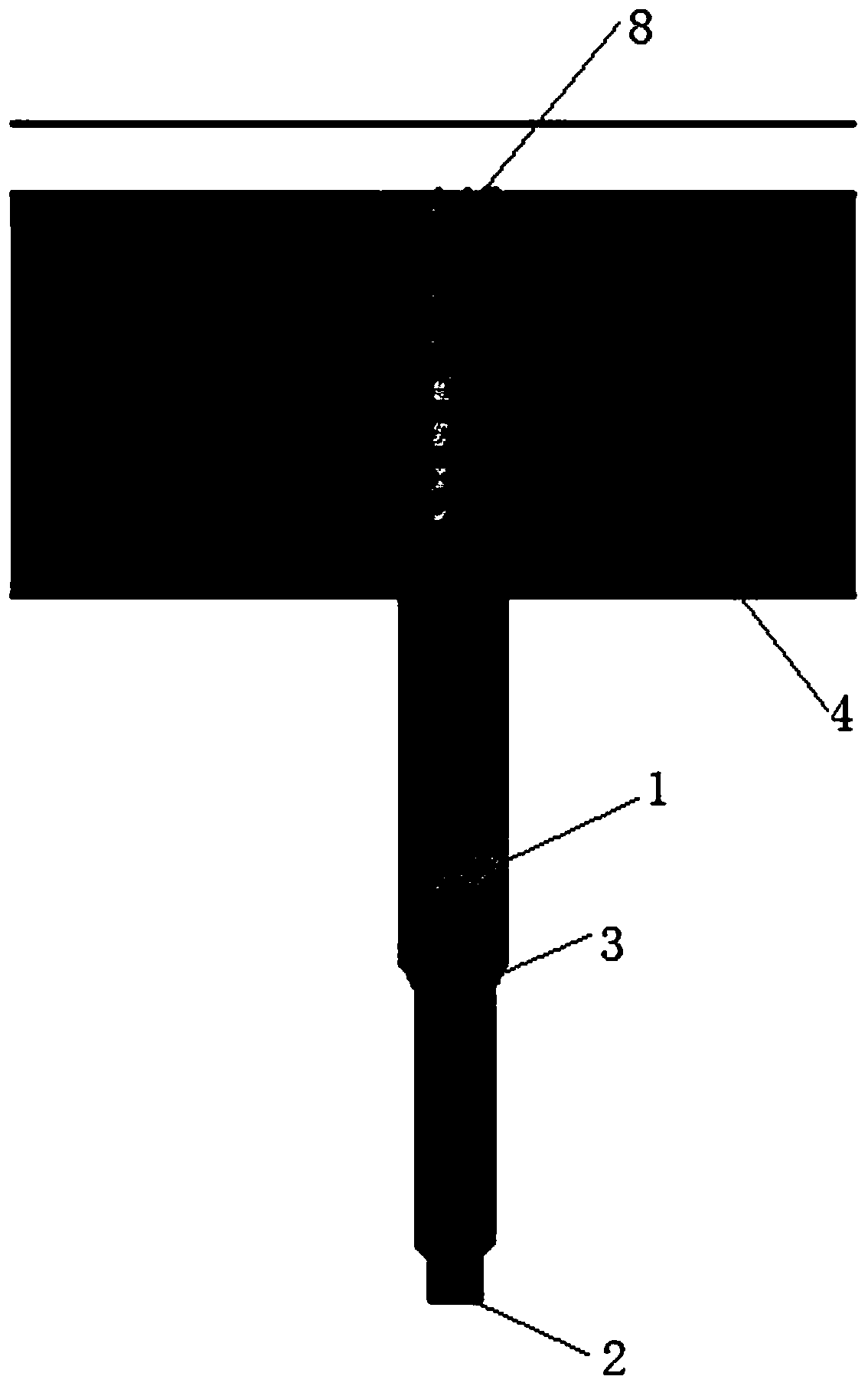

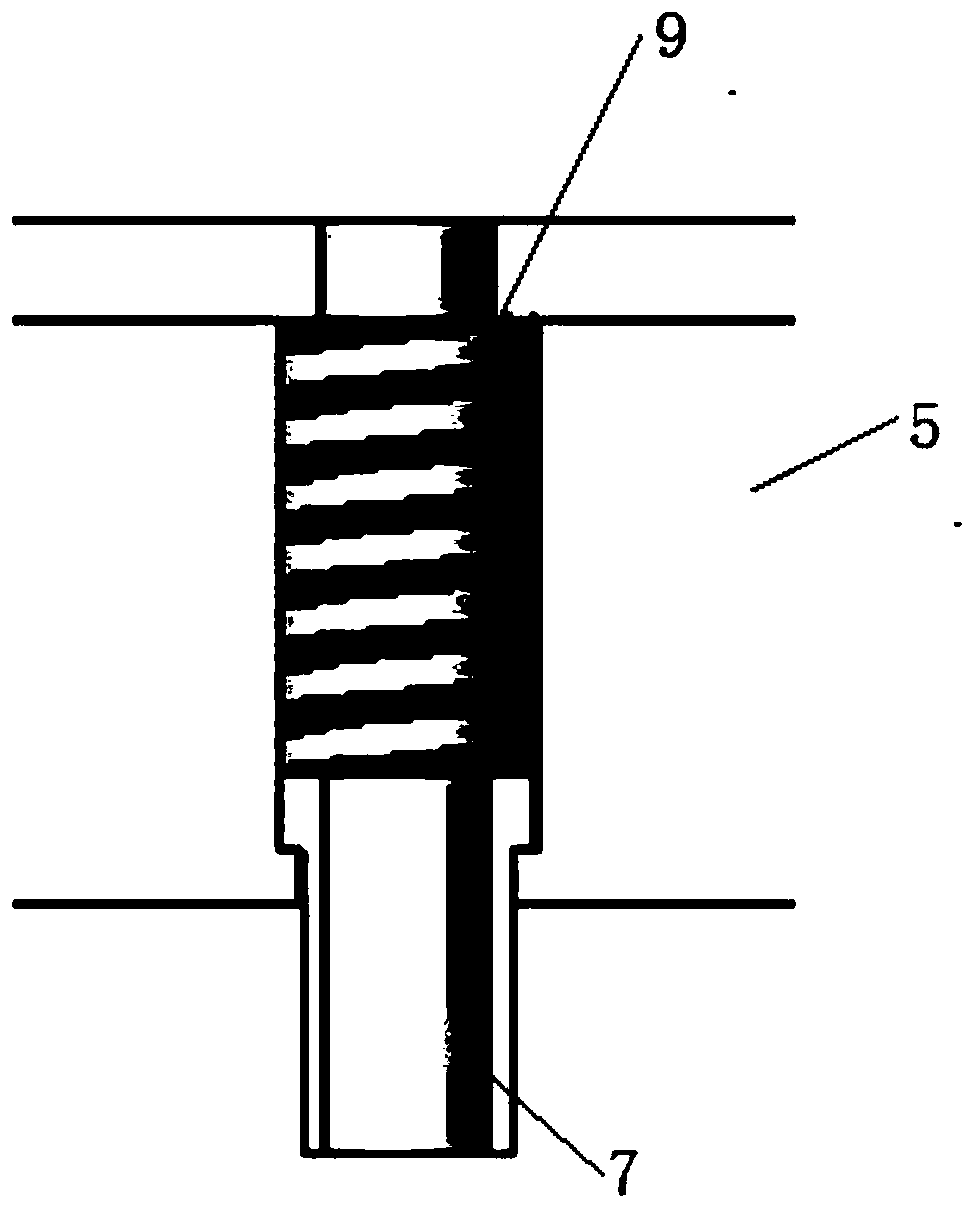

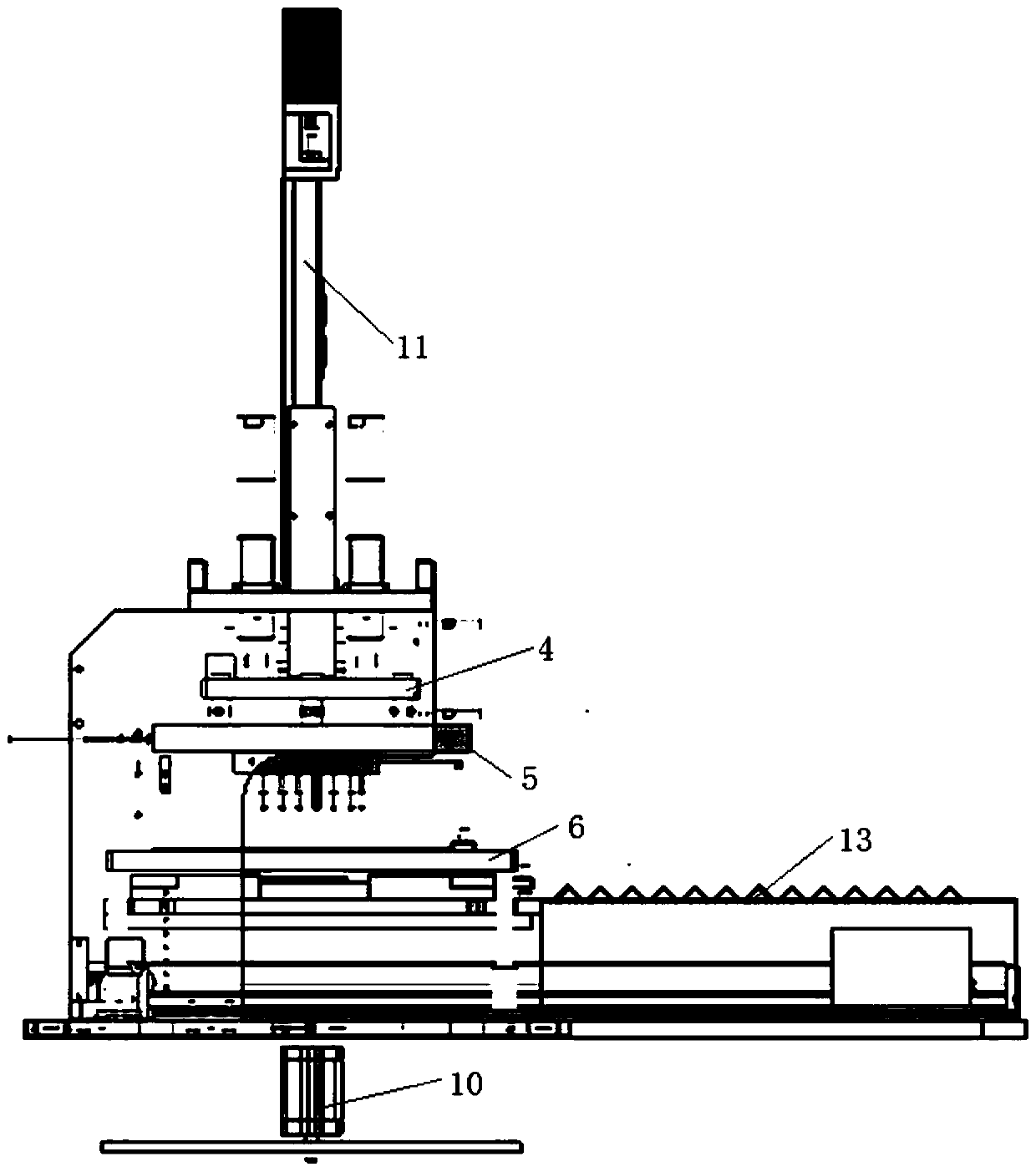

[0038] Such as Figure 1-Figure 5 As shown, the hot-melt machine system includes a cylindrical hot-melt head 1 , and a groove 2 is opened on the bottom cylindrical wall of the cylindrical hot-melt head 1 . With these grooves 2, the wall surface area of the columnar hot-melt head 1 is effectively increased, so that when the hot-melt head 1 is hot-melted, more heat can be gathered from the upper part of the hot-melt head In these grooves 2 that increase the wall surface area of the columnar hot-melt head 1, the heat accumulation on the bottom end of the columnar hot-melt head is thus increased, and finally the heat is effectively concentrated to effectively improve the columnar hot-melt head. The thermal melting point temperature at the bottom of the thermal melt head 1 achieves the effect of effectively concentrating the thermal melting point temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com