Disc type shoemaking machine

A shoe-making machine and disc-type technology, which is applied in the field of shoe-making machines, can solve the problems of increasing the wear of sole molds, affecting work efficiency, affecting positioning accuracy, and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

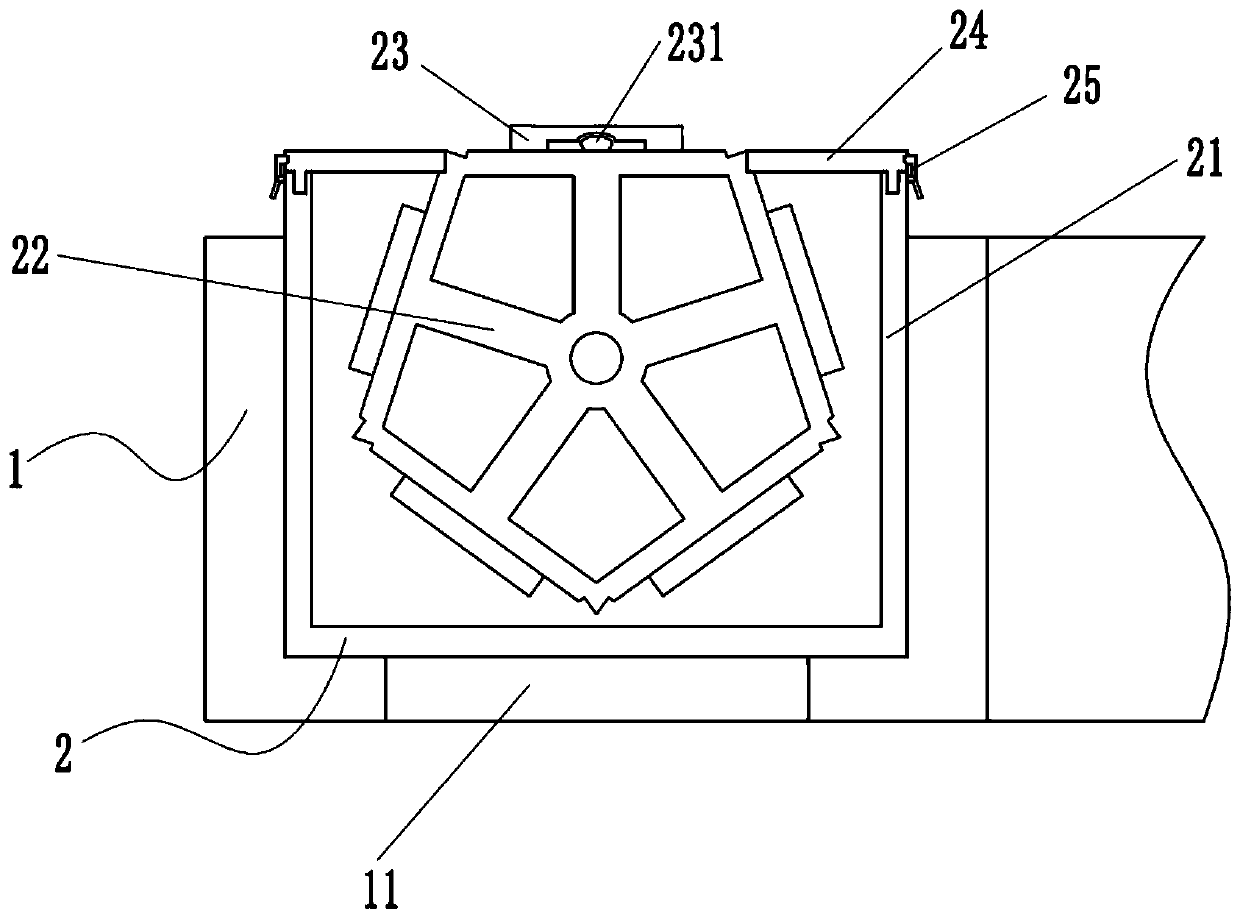

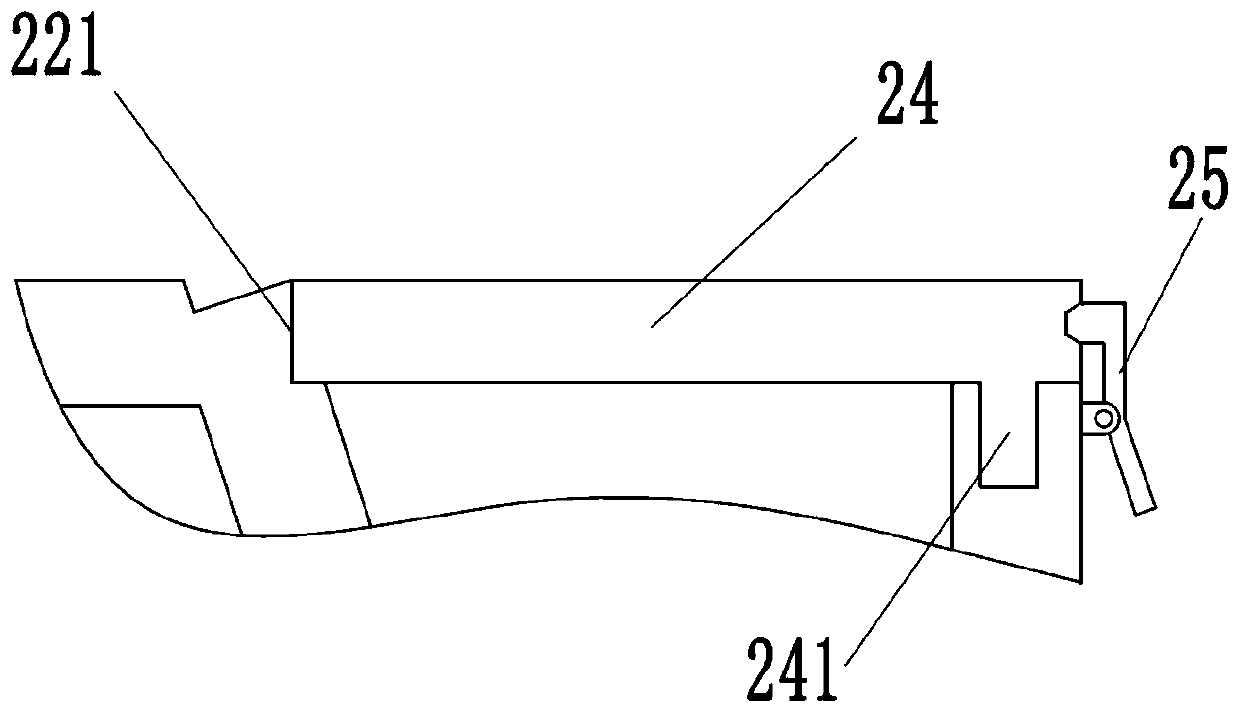

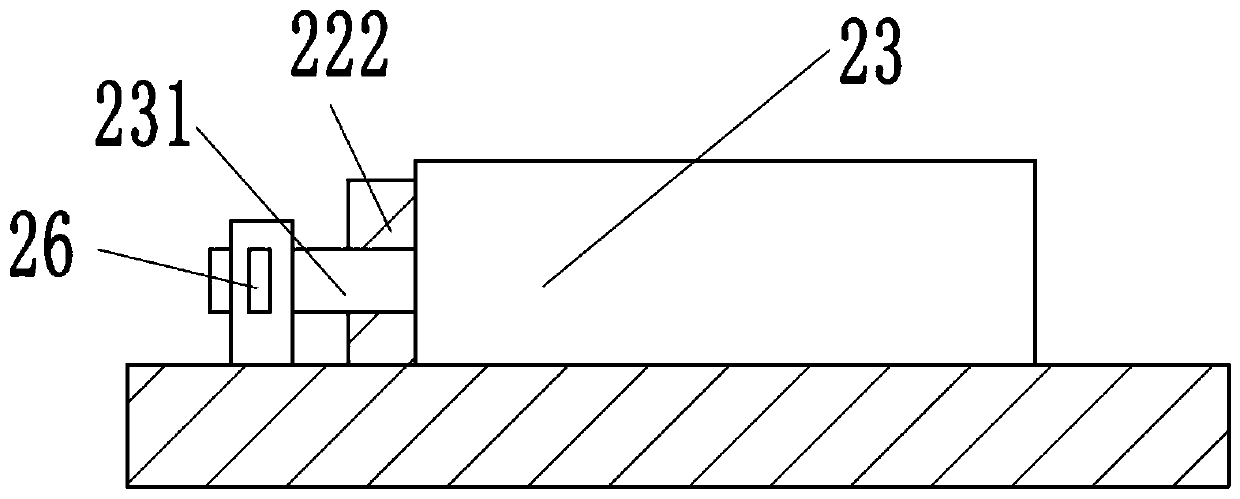

[0030] Refer below Figure 1 to Figure 5 To further explain this application, such as figure 1 A disc-type shoe-making machine shown includes a frame, an injection mechanism, a rotatable disc 1, at least one set of mold frames 2 and a clamping device arranged on the disc 1, and the mold frames 2 It includes a frame body 21 slidably arranged in a corresponding sliding hole on the disc 1, a multi-faceted turntable 22 rotatably arranged on the frame body 21, and a limit mechanism arranged on the frame body 21. The limit mechanism is used to keep the multi-faceted turntable 22 in a static state, the axis of the multi-faced turntable 22 is set horizontally, and each working plane of the multi-faced turntable 22 is respectively provided with a detachable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com