Water blowing structure for plastic-wood material processing

A wood-plastic material and processing table technology, applied in the field of wood-plastic material processing, can solve problems such as inability to adjust, achieve convenient adjustment, convenient control of direction, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

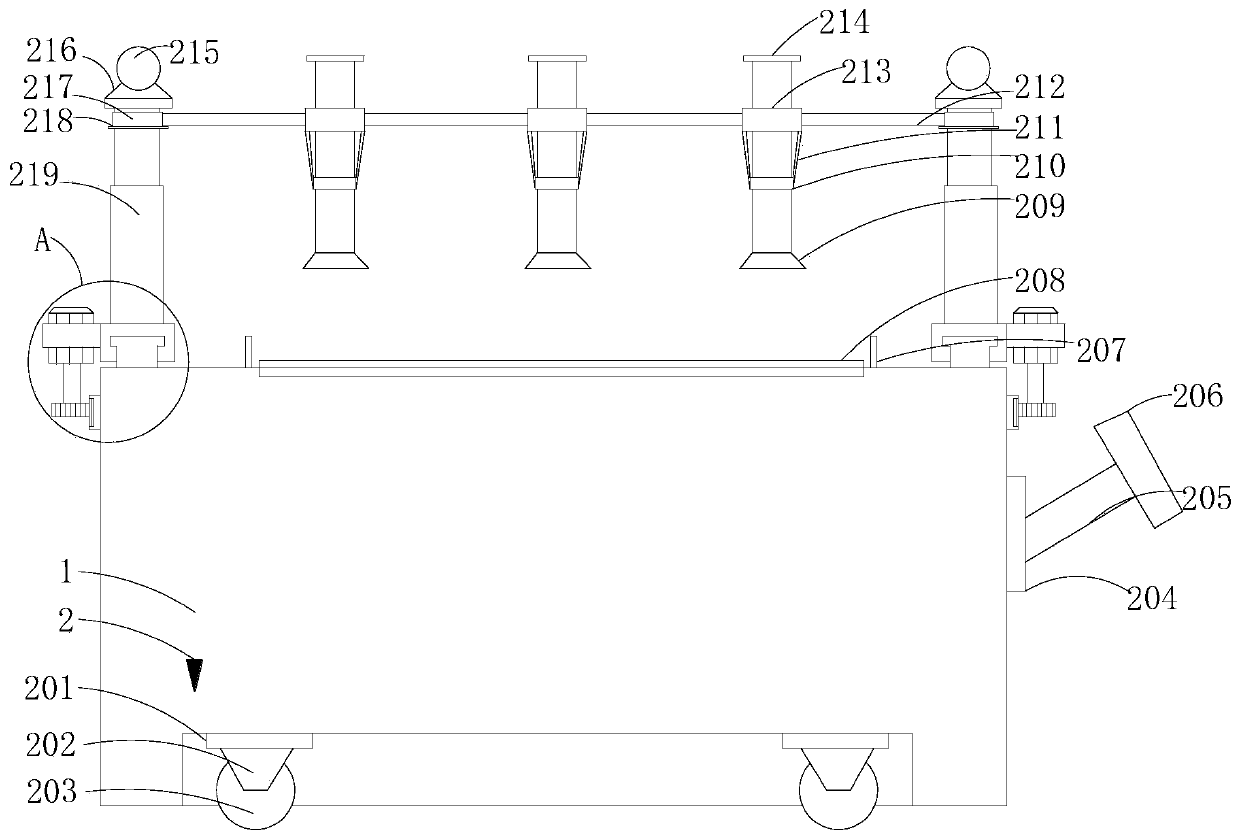

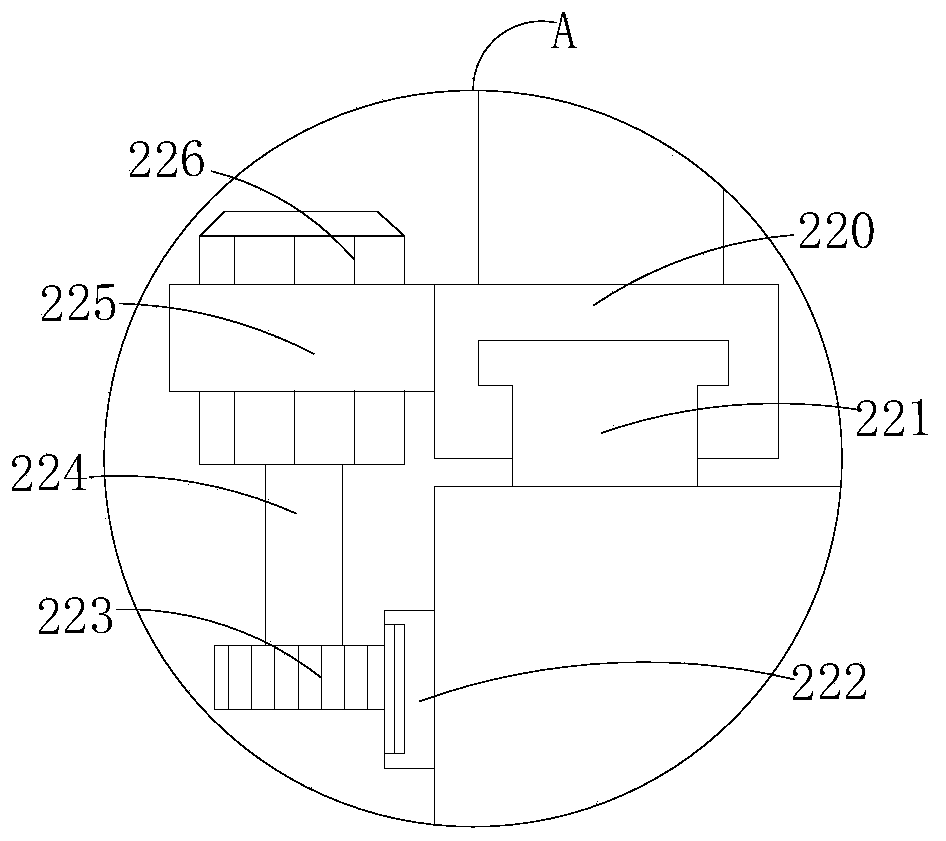

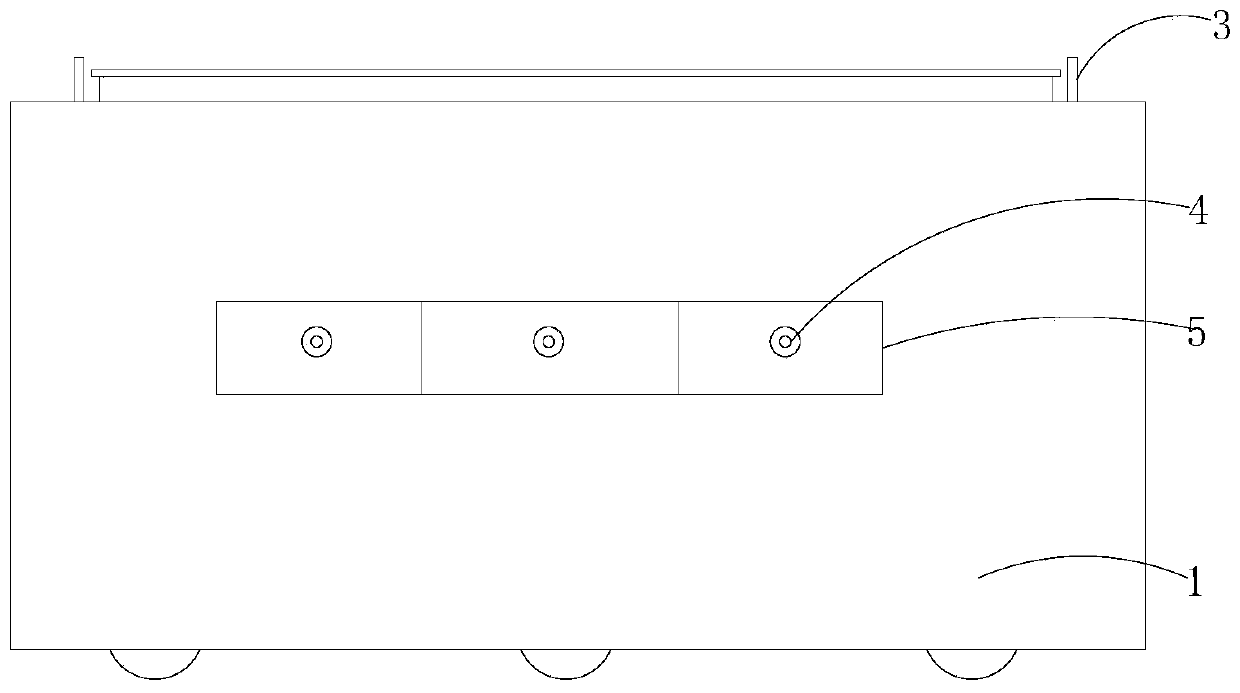

[0023] see Figure 1-4 , the water blowing structure used for processing wood-plastic materials, including a processing table 1 and an adjustment mechanism 2, and the adjustment mechanism 2 includes a top plate 201, an installation body 202, an alloy wheel 203, a side mounting plate 204, a push rod 205, a push handle 206, a limit Sheet 207, conveyor belt 208, water nozzle 209, limit ring 210, positioning sheet 211, mounting plate 212, internal thread ring 213, wafer 214, lamp ball 215, mounting seat 216, metal ring 217, baffle 218, telescopic Column 219, slide seat 220, slide rail 221, tooth plate 222, gear 223, rotating shaft 224, fixed ring 225 and driving motor 226, the outer surface top left side of processing table 1 is welded with the outer surface bottom of slide rail 221, slide The top of the outer surface of the rail 221 is slidingly connected with the inner surface of the slide seat 220, the left side of the outer surface of the slide seat 220 is welded to the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com