Production process for intelligent automatic preparation of environment-friendly rubber for vehicles

A technology of environmentally friendly rubber and production technology, which is applied in metal processing and other directions, can solve the problems of high labor input costs and low processing efficiency, and achieve the effects of wide application range, improved work efficiency, and no residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

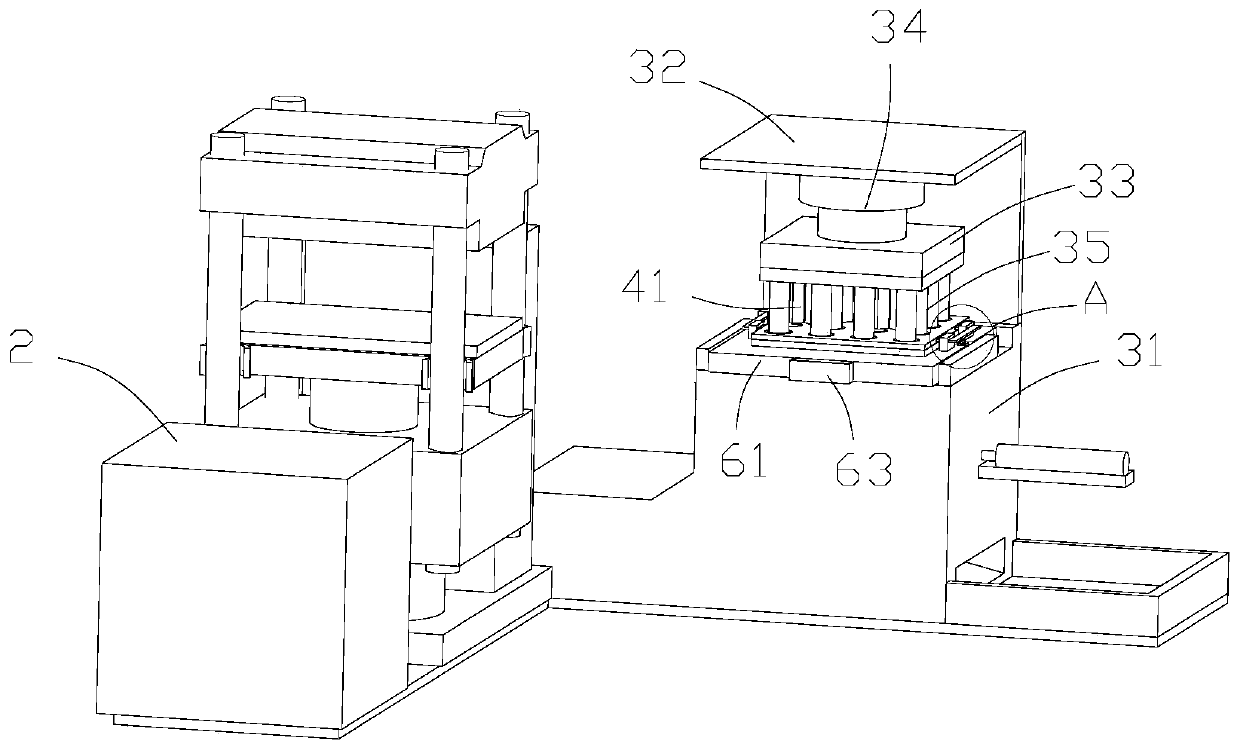

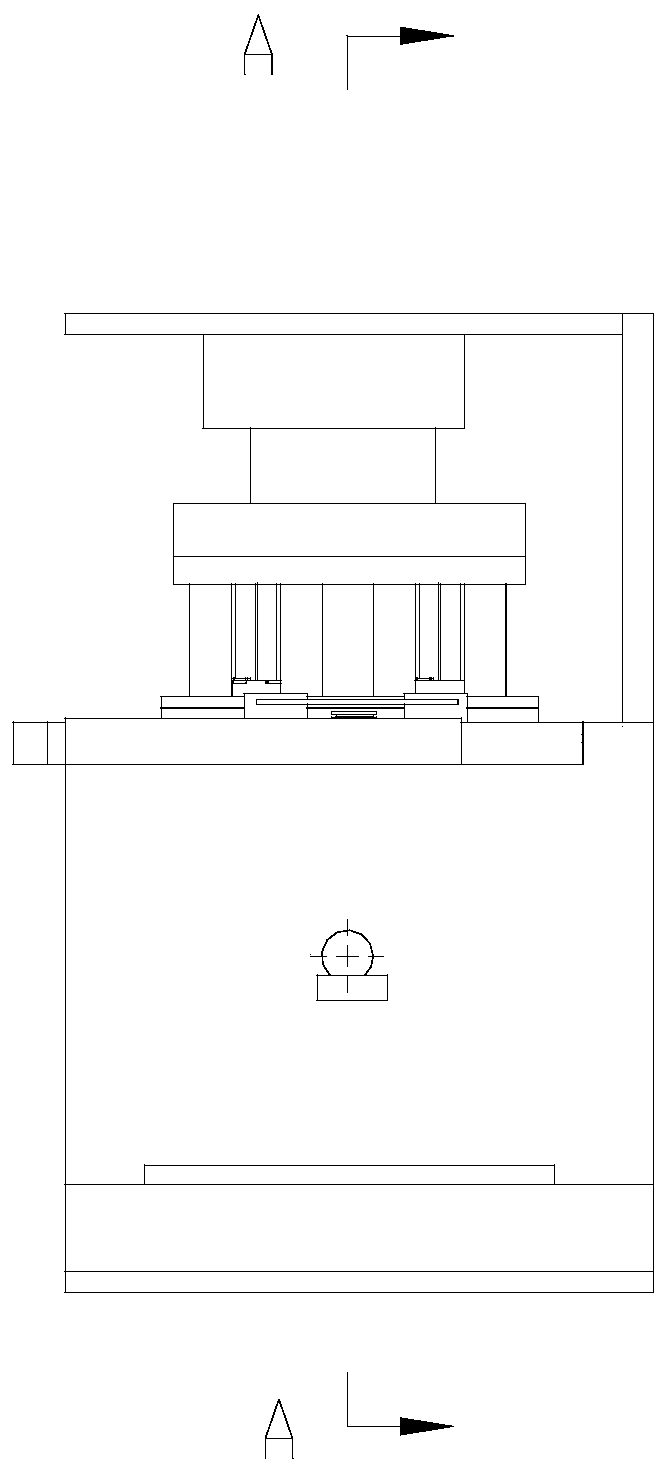

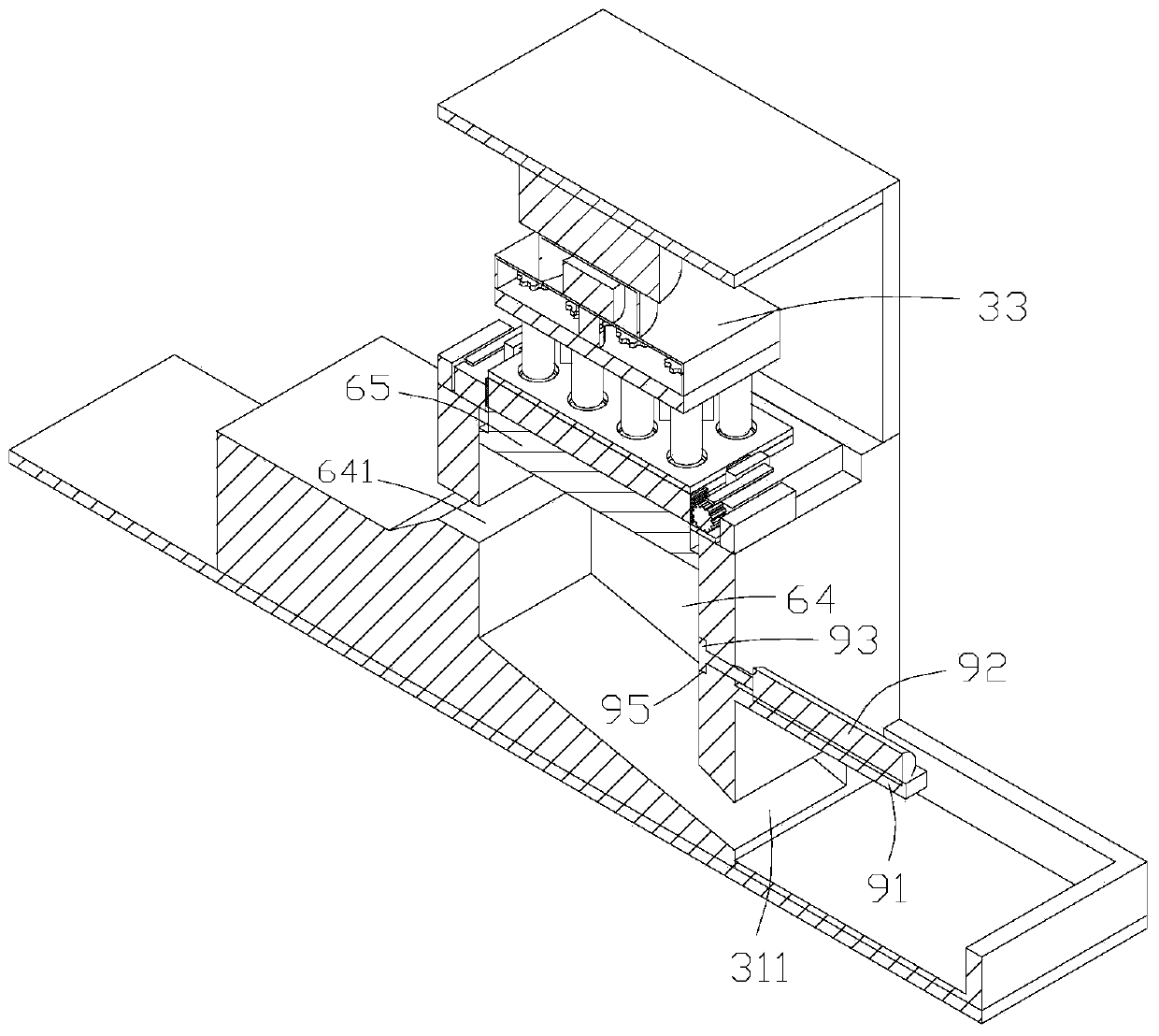

Image

Examples

Embodiment Construction

[0034] A production process based on the intelligent automatic preparation of environmentally friendly rubber for vehicles, comprising the following steps:

[0035] a. Weighing raw materials: use a weighing device to weigh each raw material;

[0036] b. Internal mixing: put the weighed raw materials into the internal mixer, and react in the internal mixer to obtain the mixed rubber;

[0037] c. Open refining: use the open refining equipment to open the mixed rubber to obtain the film, and then spray or soak the release agent on the film; among them, the film is isolated by soaking the release agent in the soaking pool, and the soaking pool has a release agent , the film is put into the soaking tank for soaking

[0038] d. Blow the film through the cooling fan to cool the film soaked in the release agent;

[0039] e. using a cutting machine to cut the film obtained in step d to obtain a semi-finished product;

[0040] f. Vulcanize the semi-finished product through vulcanizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com