Bracket of centerless grinding machine

A centerless grinding machine and bracket technology, which is applied in the field of brackets for lifting workpieces, can solve the problems of difficulty in improving the machining accuracy of positioning holes, poor realization accuracy, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

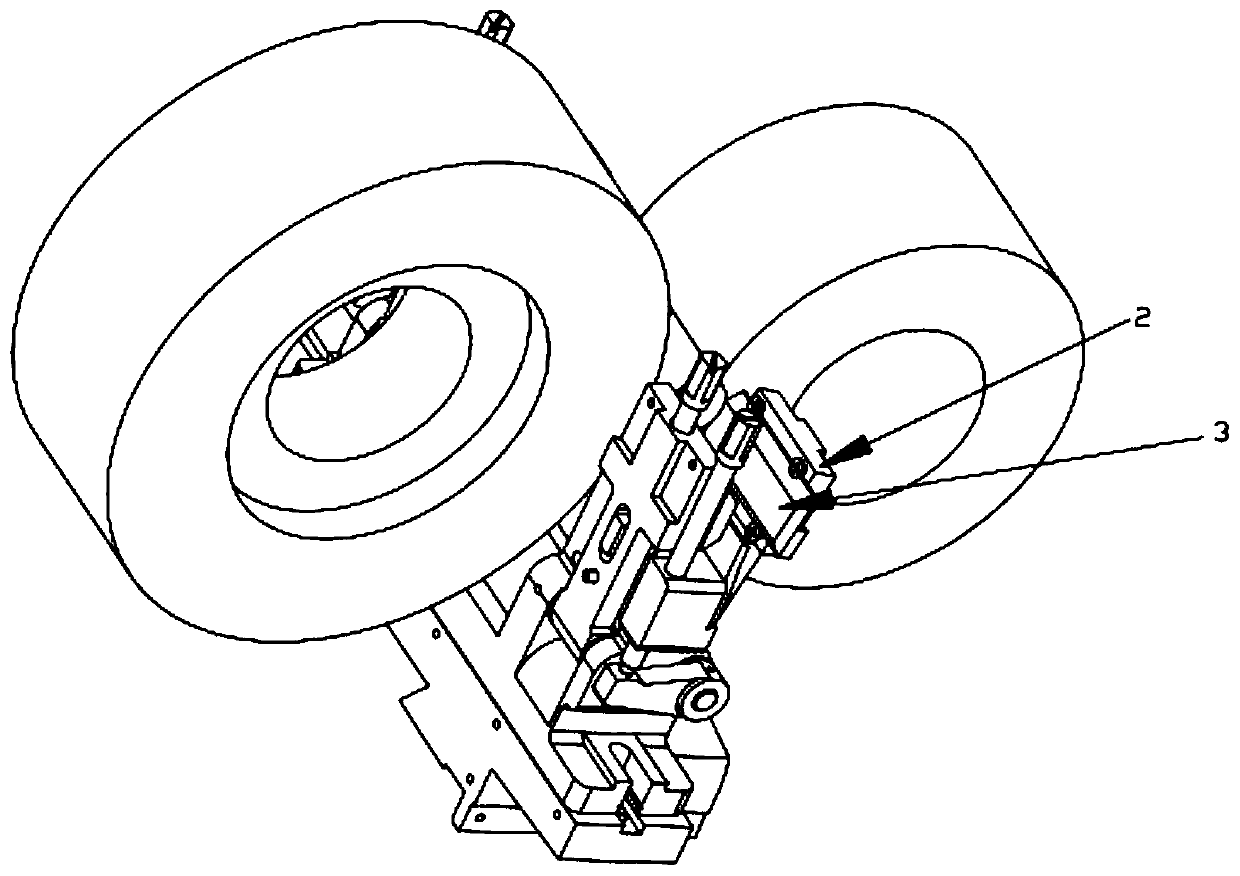

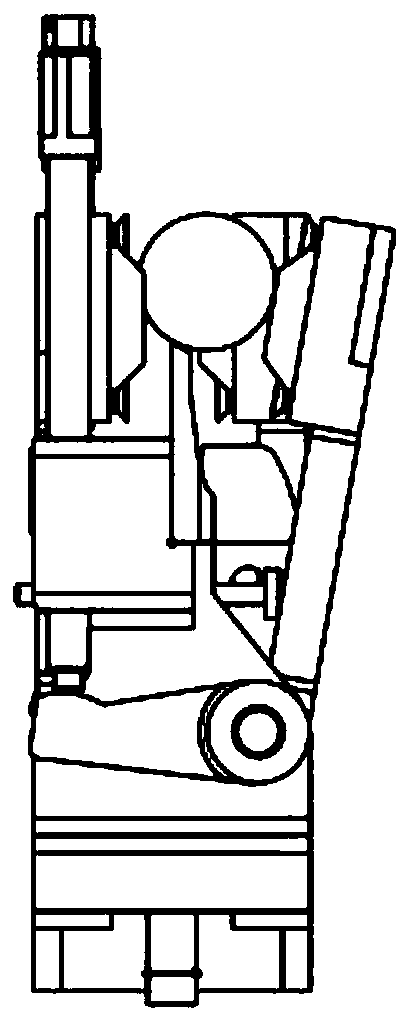

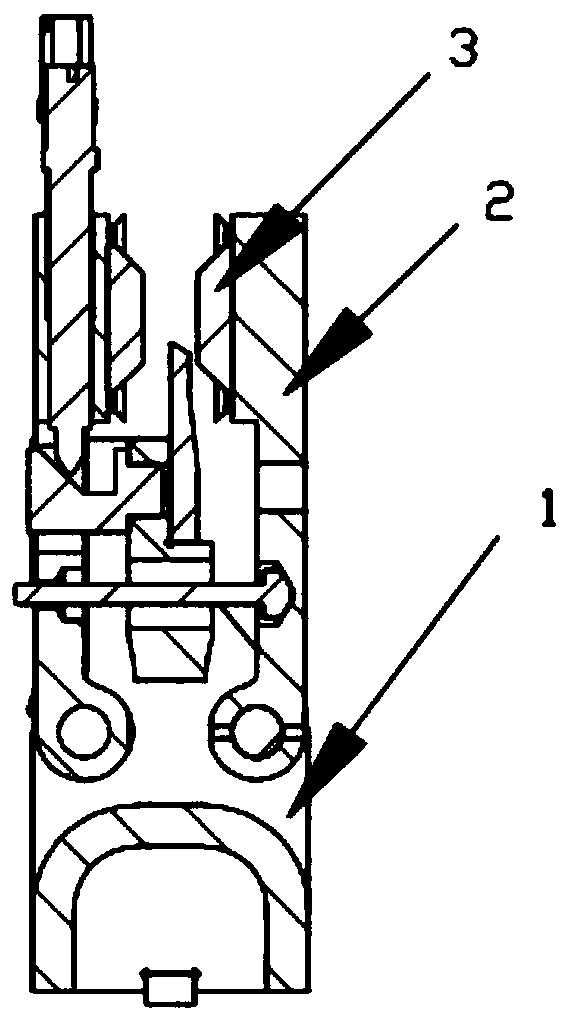

[0026] Such as Figure 4-Figure 11 The shown centerless grinding machine bracket includes a bracket base 1, a jaw 2 movably connected to the bracket base 1, a pallet 13 fixed on the bracket base 1, and a bracket connected to the jaw 2. The guide plate 3, the lower end of the bracket base 1 is connected with a slide plate 4, the jaws 2 described in this embodiment are two groups, and two groups of two are arranged symmetrically, and there are guide plates 3 snapped into each jaw 2. In this embodiment, the groove connects the pressing block 7 at the end of the jaw 2 so that the pressing block 7 extends to the lower end surface of the guide plate 3 and the jaw 2 to form a dovetail groove 5, and the guide plate 3 snaps into the groove. The groove has a gap for adjusting the angle of the guide plate 3, and the jaw 2 is provided with a first adjusting member 6 for adjusting the angle of the guide plate 3, and the guide plate 3 is clamped in the dovetail groove 5 and fixed by the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com