Zone-limiting welding power supply

A welding power source and position-limiting technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increasing the difficulty of maintenance of subsequent devices, the influence of the work of adjacent devices, and the weakening of the internal cooling effect. , to ensure positioning stability and application security, reduce support strength requirements, ensure the quality of operation and the effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

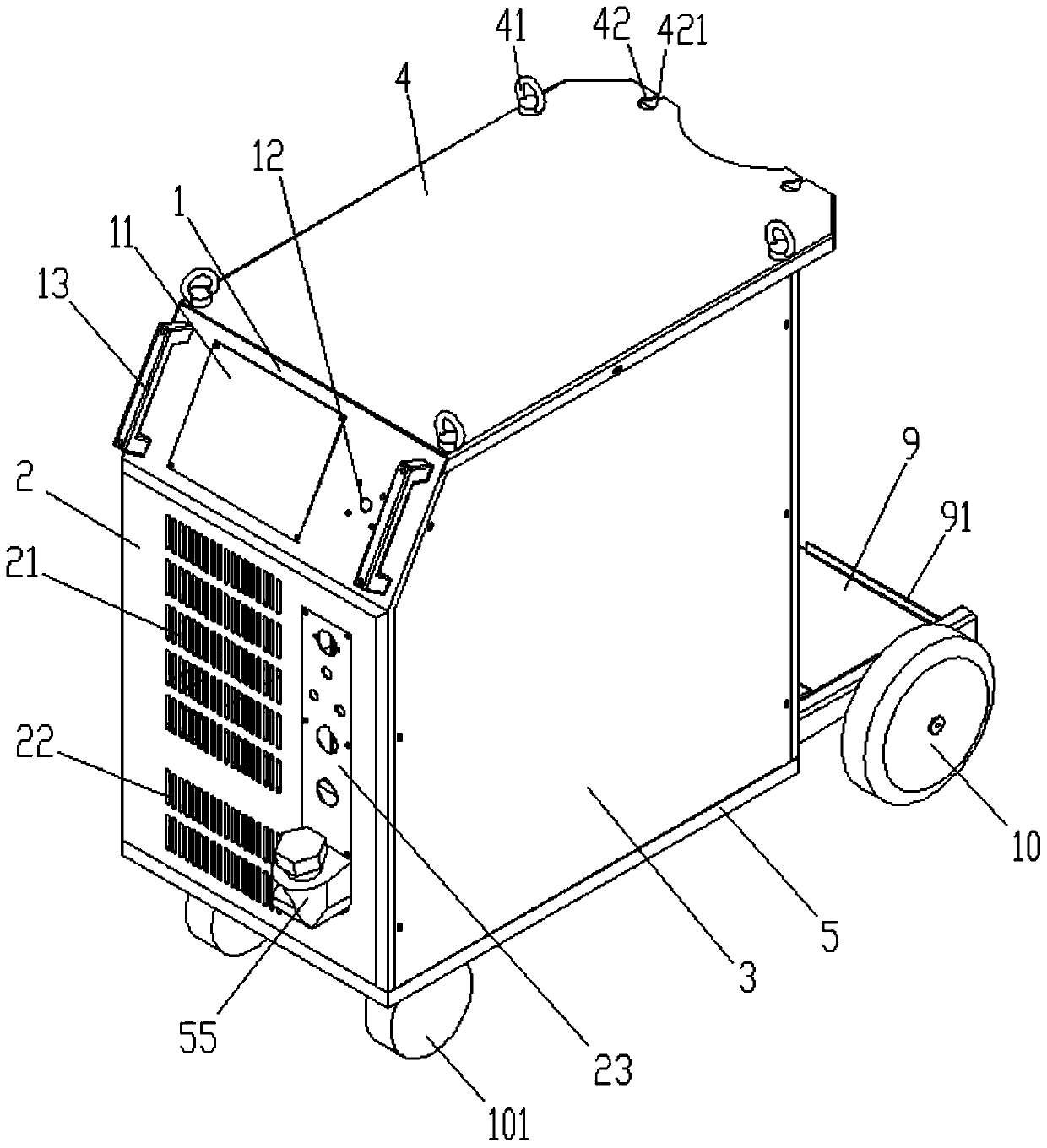

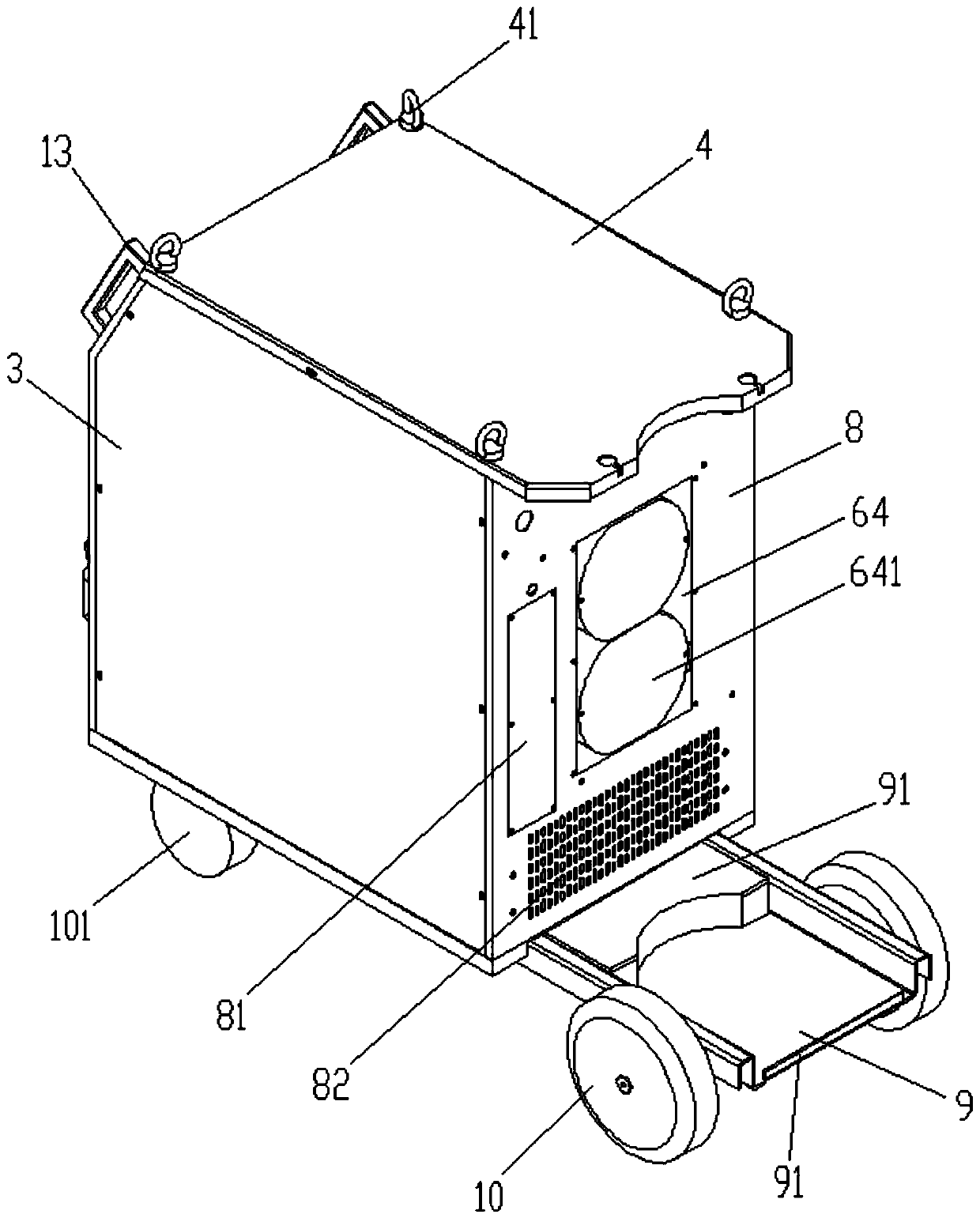

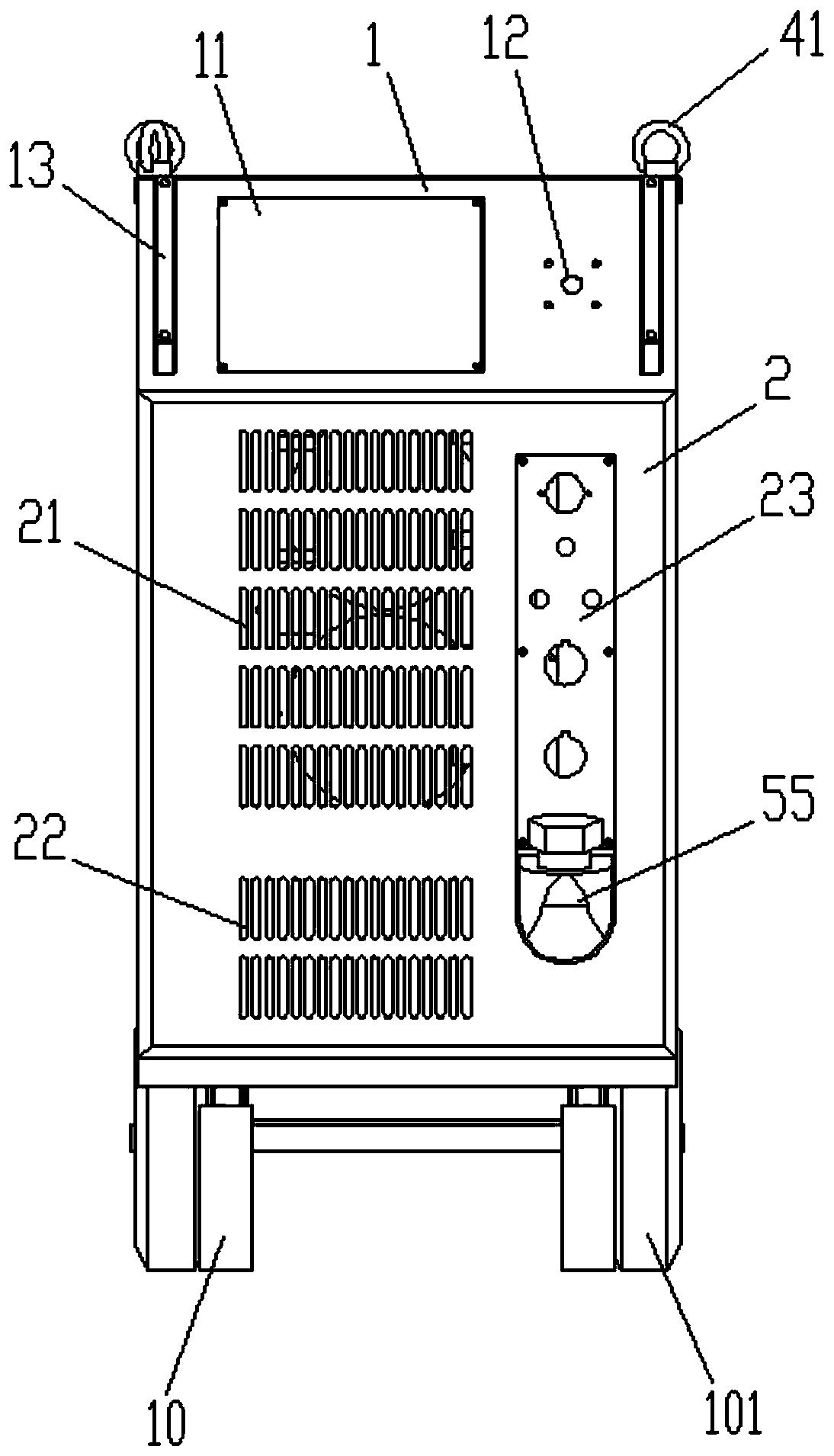

[0030] Such as figure 1As shown above, the welding power source is surrounded by the front plate, side plate 3, rear plate 8, top plate 4 and welding bottom plate 5, and the gas cylinder fixing position is set behind the welding bottom plate 5 and the rear plate , so as to realize the placement of the back-type gas cylinder, ensure the stability of the positioning and the effect of the device.

[0031] The welded bottom plate 5 can be set as a rectangular plate with a width less than 477mm according to the application environment, so as to meet the passing diameter of a standard door and ensure the displacement quality of the device. At this time, as shown in the figure, the front plate, the side plates 3 and the rear plate 8 are vertically connected to the four ends of the welded bottom plate 5 and realize the screw fastening connection of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com