Pipeline mixer

A pipeline mixer and pipeline technology, applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of unable to adjust the mixing intensity, long mixing time, uneven mixing, etc., to improve the water treatment effect, The effect of short mixing time and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

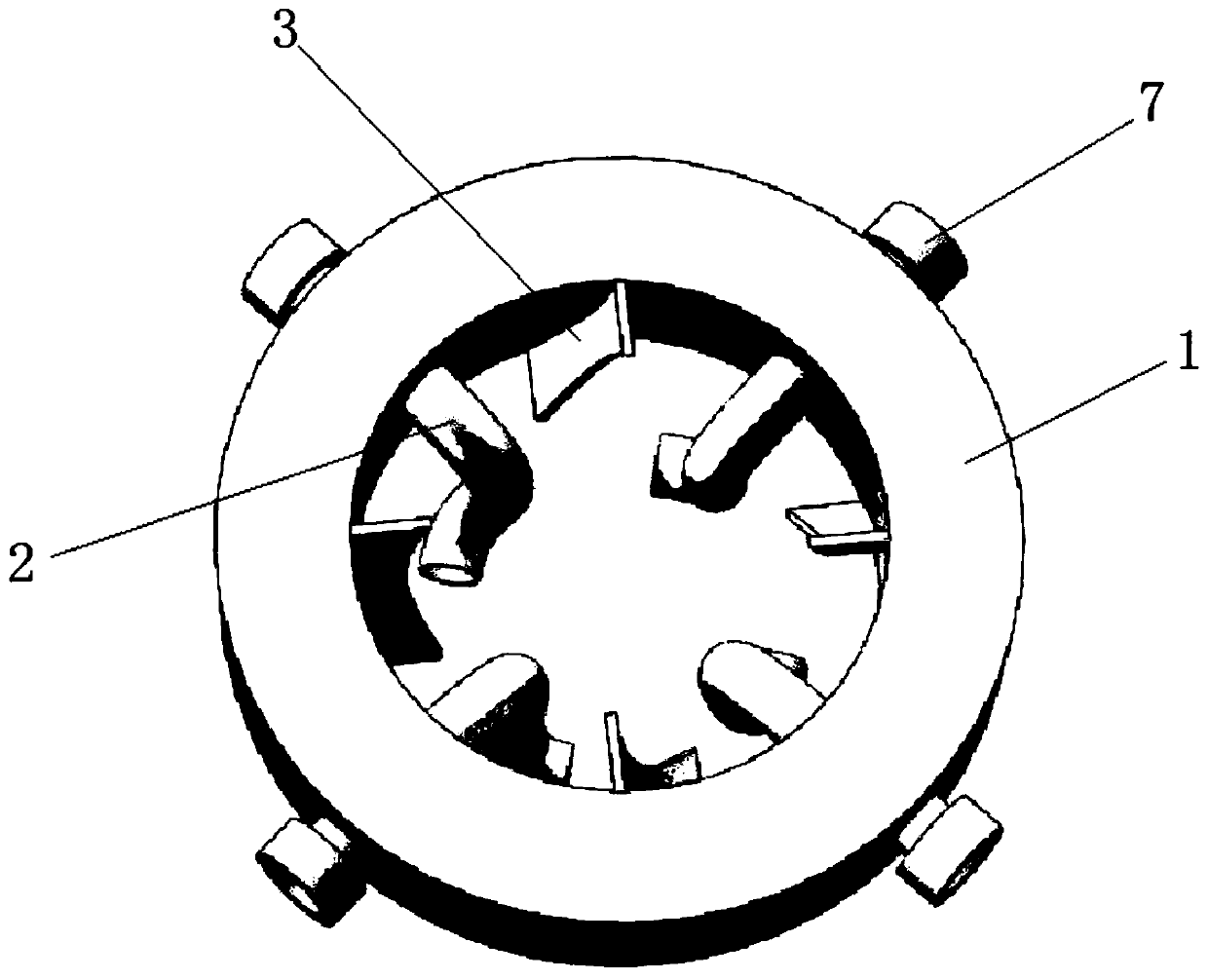

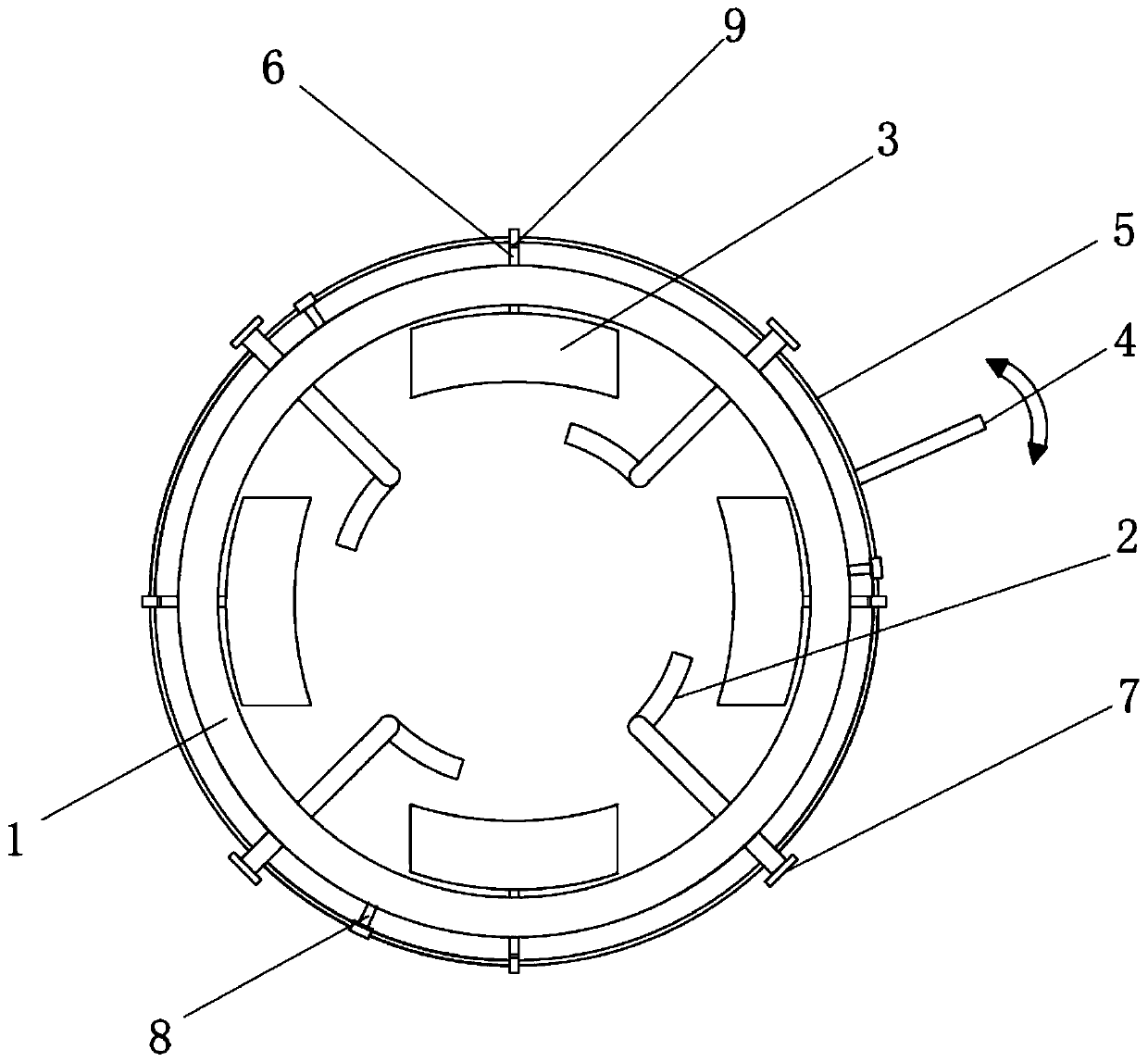

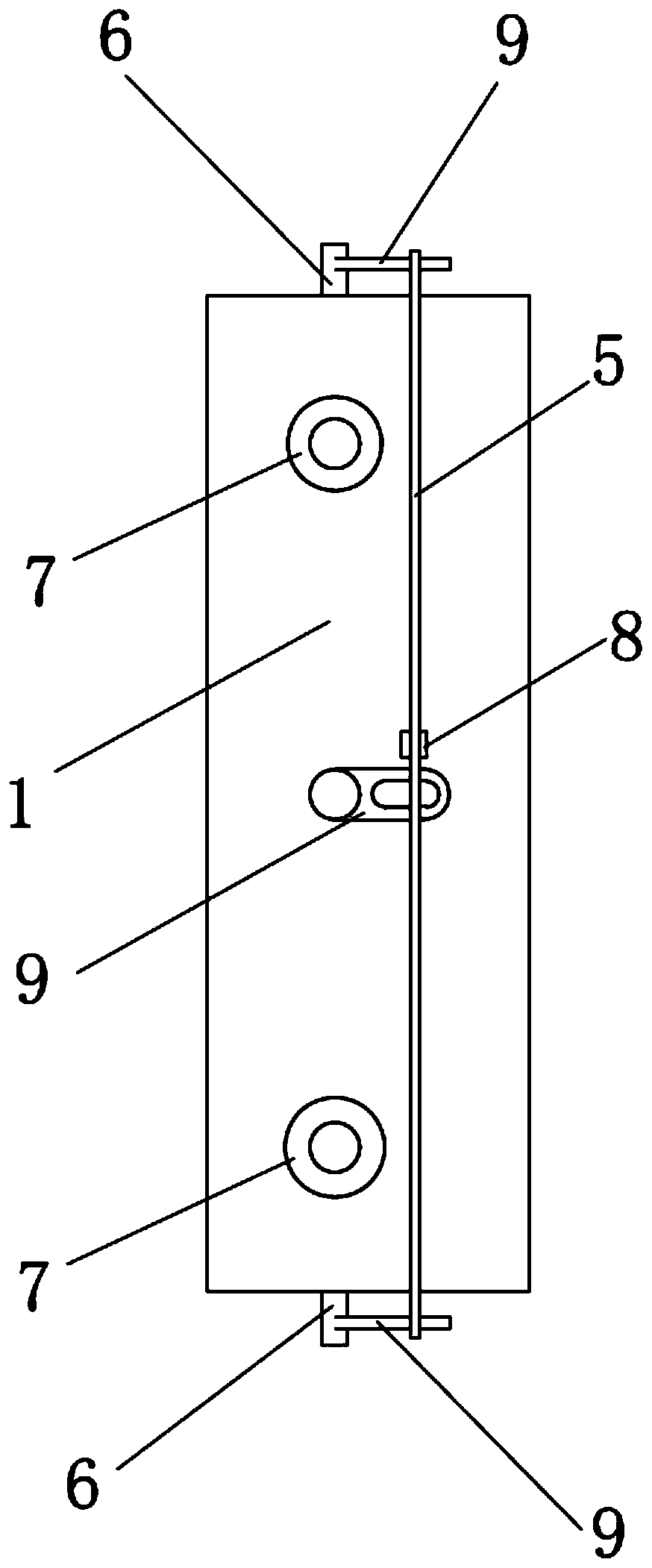

[0035] like Figure 1-Figure 6 As shown, the pipeline mixer is installed between the end faces of two pipelines through the flanges clamped at its two ends, which can reduce or eliminate the radial stress at the pipeline connection. The pipeline mixer comprises a cylindrical shell 1, on which four liquid inlet pipes 2 are evenly arranged along the circumferential direction; in the cylindrical shell 1, four swirl fins 3 are evenly distributed along the circumferential direction; in order to lift Liquid mixing effect, four liquid inlet pipes 2 and four swirl fins 3 are arranged at intervals.

[0036] When the fluid in the pipeline flows through the swirl fins 3, a rotational force is generated to make the fluid swirl; the above-mentioned swirl fins 3 are set in the same direction, and the angle can be adjusted by the adjustment mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com