Efficient purification device for calcium-method wet desulfurization tower direct-discharge chimney wet smoke plume, and applications thereof

A technology of wet desulfurization and purification equipment, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of undiscovered patent publications, increased maintenance costs, increased investment costs, etc., to reduce energy consumption and energy consumption and low investment cost, the effect of reducing investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below. It should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0036] The structures, connections and methods not described in detail in the patent of the present invention can be understood as common knowledge in the field.

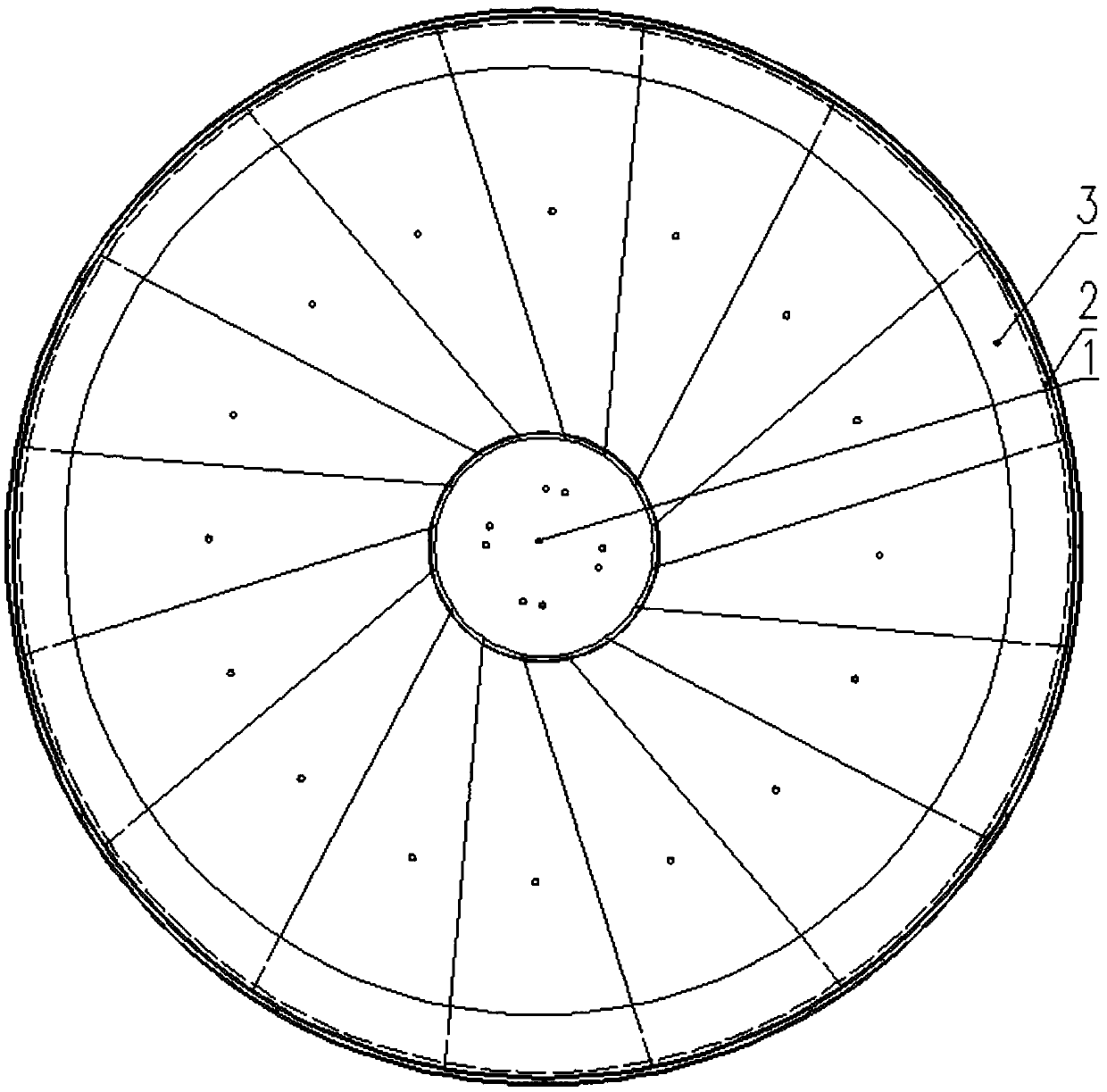

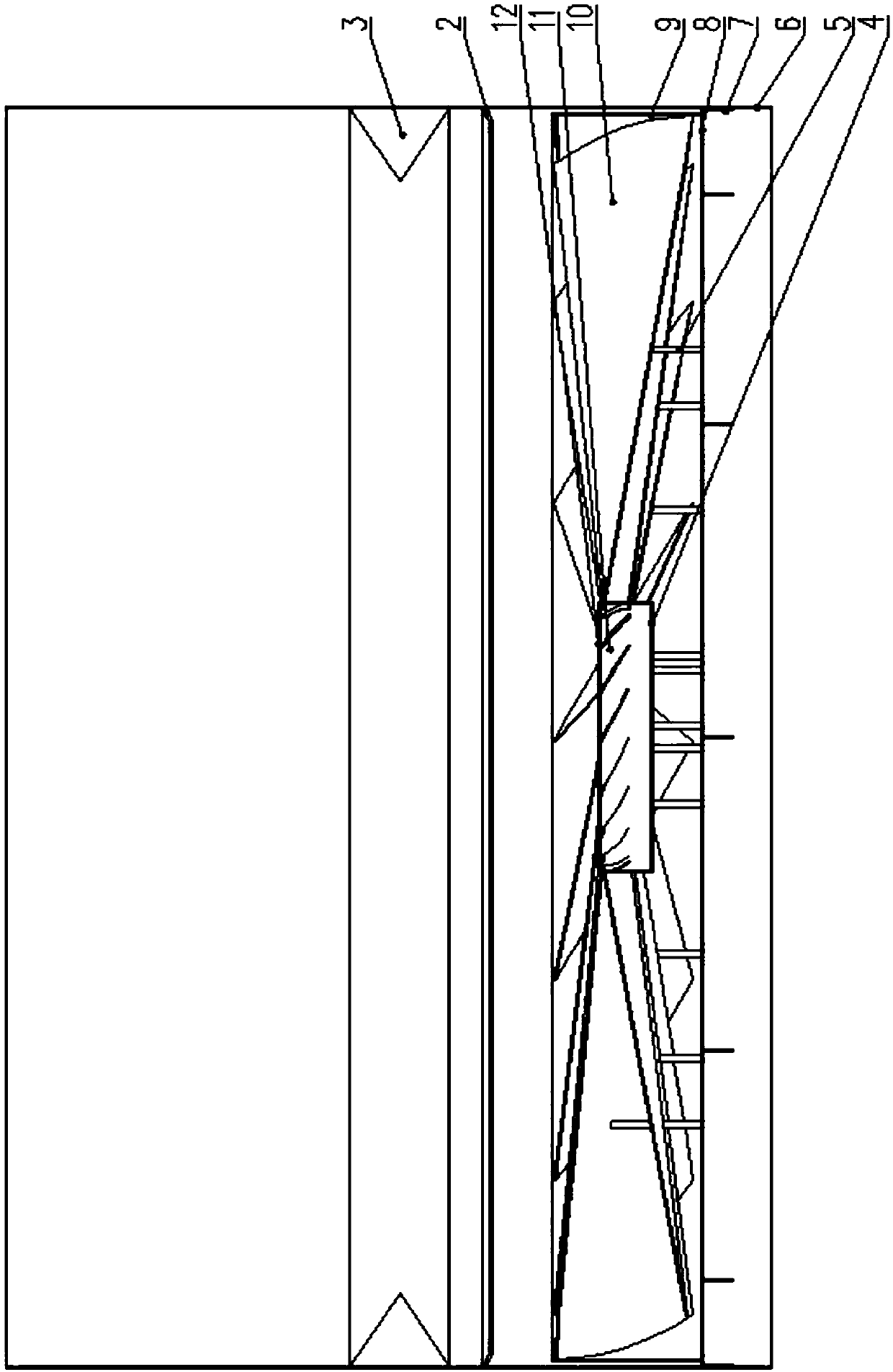

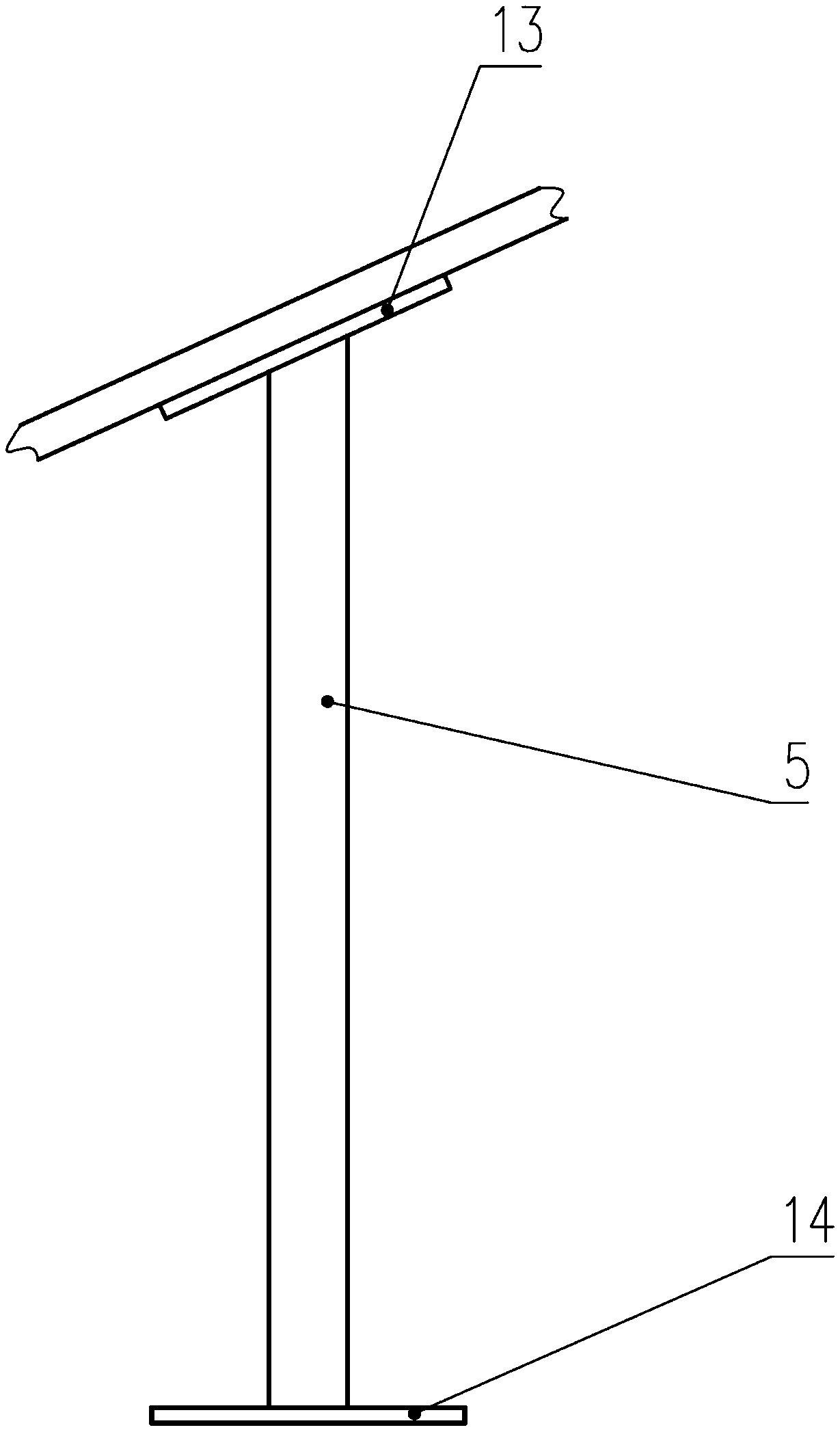

[0037] A high-efficiency purification device for the wet smoke plume of a calcium-based wet desulfurization tower straight exhaust chimney, such as figure 1 As shown, the device includes a flue gas purification unit 1, a water retaining ring 2 and a deflector 3, the water retaining ring is coaxially arranged above the flue gas purification unit, and the deflector is coaxially arranged at intervals Above the water retaining ring, and the central axis of the flue gas purification unit, water retaining ring, deflector is consistent with the central axis of the chimney 6 on the top of the absorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com