Pipe device having a bonded joint

A technology that combines connection and pipe fittings, applied in the direction of hose connection devices, pipes/pipe joints/fittings, pipe connection arrangements, etc., can solve problems such as leakage, small torque, etc., and achieve low leakage rate, increased area, and high tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

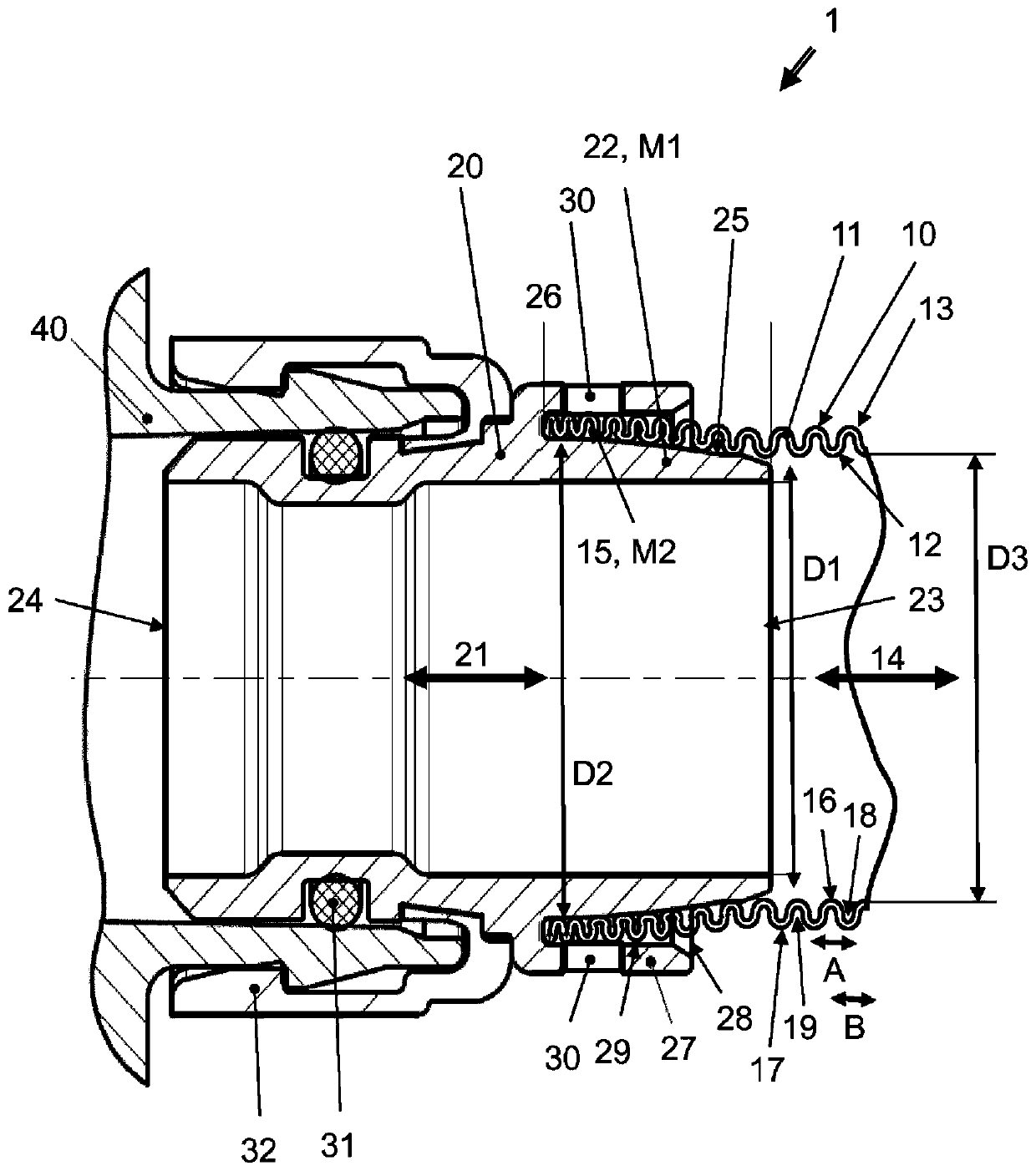

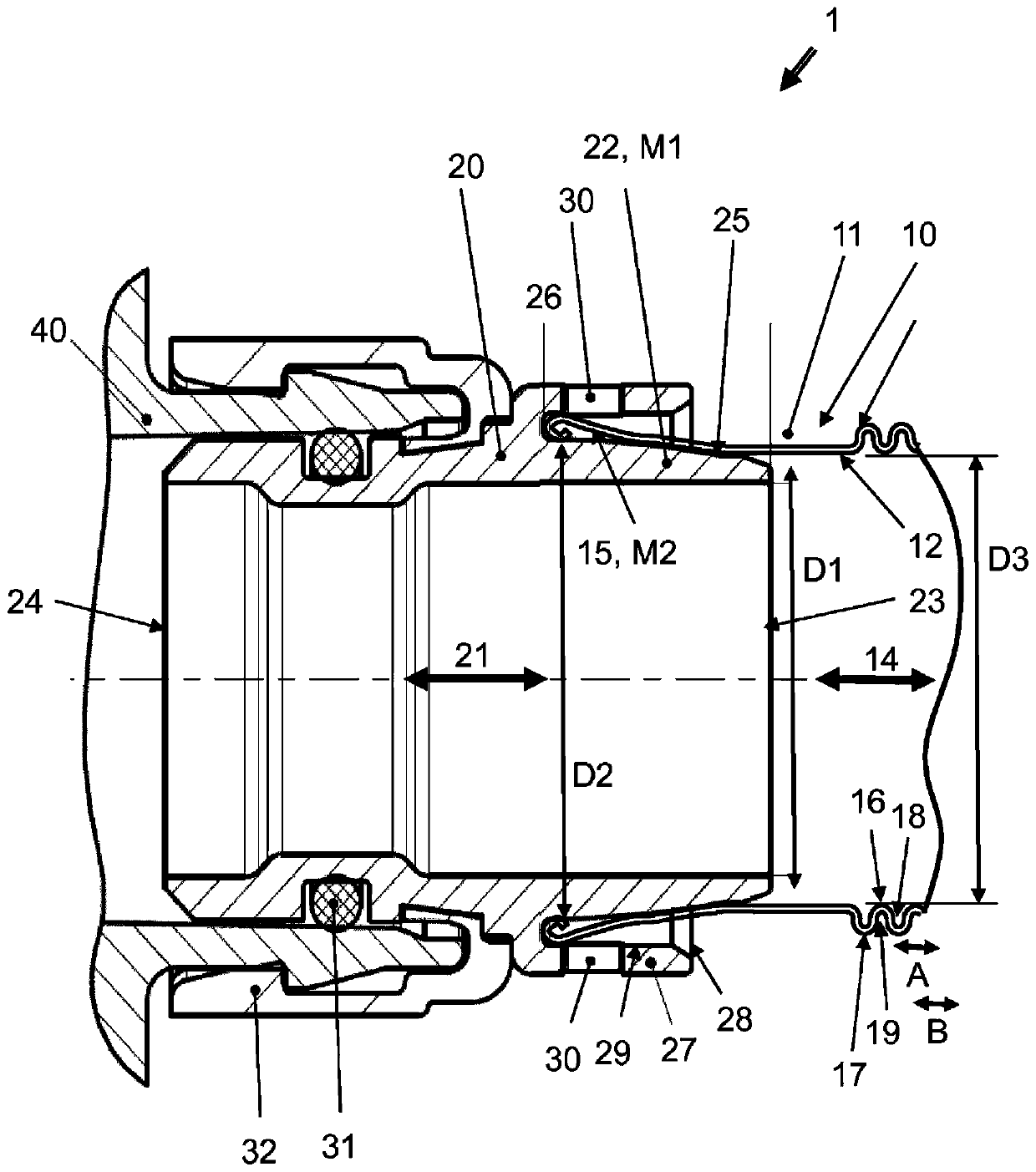

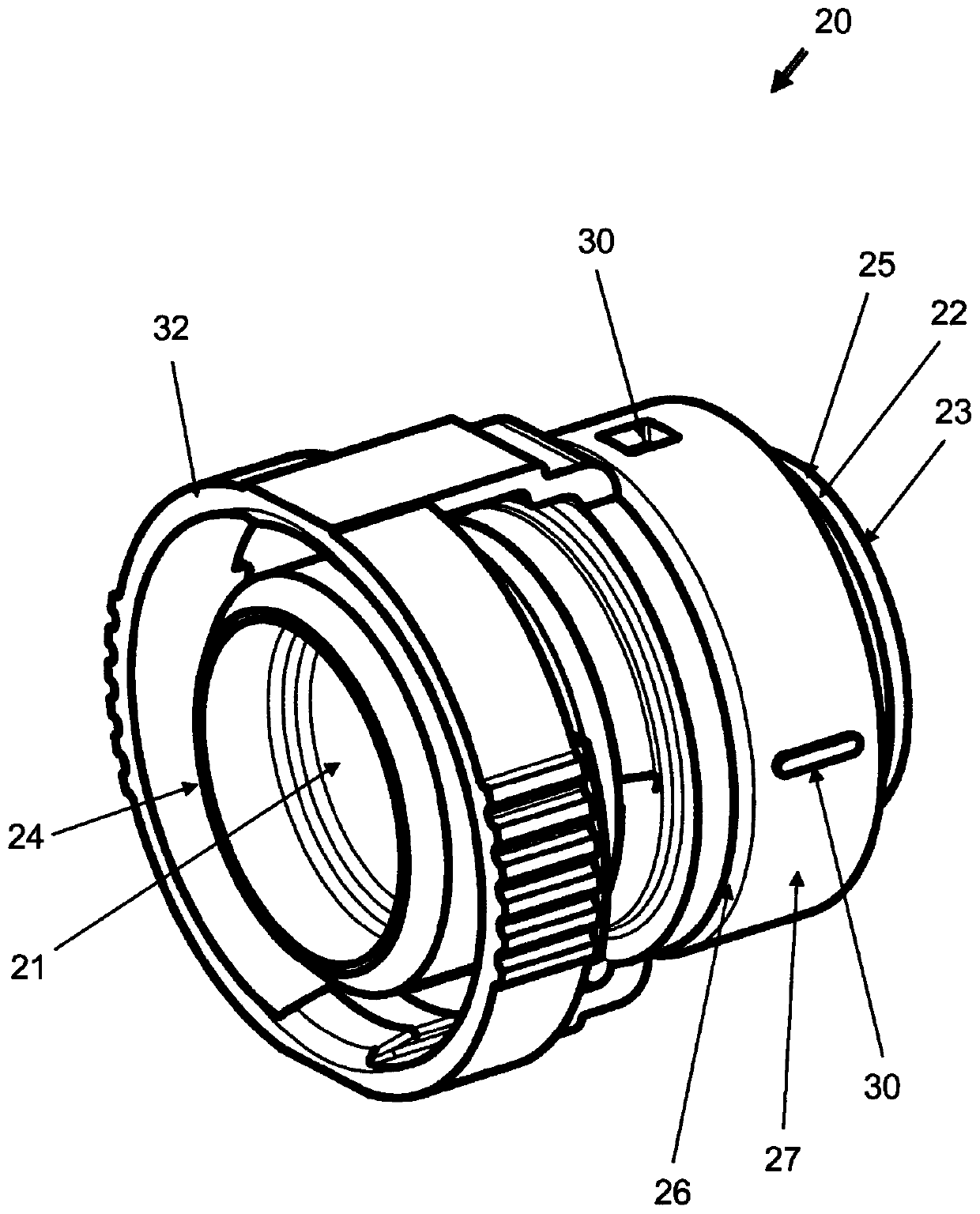

[0036] figure 1 and figure 2 Respectively shows a longitudinal section of a pipe arrangement 1 with a pipe 10, a connecting element 20, or a pipe connection between the pipe 10 and the connecting element 20, the pipe 10 is a corrugated pipe fitting. image 3 In addition, a perspective view of the connecting element 20 is shown.

[0037] according to figure 1 , 2 The connecting element 20 of and 3 forms a through passage 21 extending from a connecting piece 22 to a second opening 24 , and the connecting piece 22 has a first opening 23 . The through channel 21 is straight, which means that the through channel 21 does not produce any direction change. The connecting piece 22 forms an outer peripheral surface 25 and has a stop portion 26 and an outer peripheral collar 27 . An annular gap 28 is formed between the outer peripheral collar 27 and the outer peripheral surface 25 of the connecting member 22 . The annular gap 28 opens in a longitudinal direction and in the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com