Atomic gas chamber temperature closed-loop control method based on optical pumping saturated absorption

An atomic gas chamber and temperature closed-loop technology, applied in temperature control, physical/chemical change thermometers, thermometers, etc., can solve the problem that a single thermistor cannot truly reflect the temperature change of the gas chamber, limit the adjustability of the temperature control range, and Flexibility, magnetic field interference and other issues, to achieve the effect of avoiding magnetic field interference, improving adjustability, and reducing the influence of temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

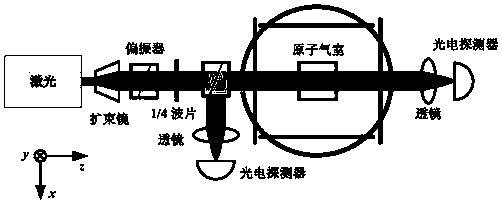

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0046] A method for closed-loop temperature control of an atomic gas cell based on optically pumped saturated absorption, comprising the following steps:

[0047] (1) Temperature measurement based on optically pumped saturated absorption

[0048] The light intensity signal transmitted through the gas cell is closely related to the saturated vapor pressure density of atoms in the atomic gas cell. The fluctuation of the gas cell temperature will directly affect the saturated vapor pressure density, and then affect the transmitted light intensity. Therefore, the temperature information of the gas chamber can be directly calculated by detecting the light intensity signal passing through the gas chamber.

[0049] Step 1: The laser generates laser light corresponding to the atomic energy level transition frequency, which is divided into tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com