Sample pretreatment device capable of automatically identifying liquid level height and sample treatment device

A technology of sample pretreatment and liquid level height, applied in the field of analytical chemistry, can solve the problems of many operations required, high cost, complicated centrifugation operation, etc., and achieve the effect of avoiding centrifugation operation, precise pipetting, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

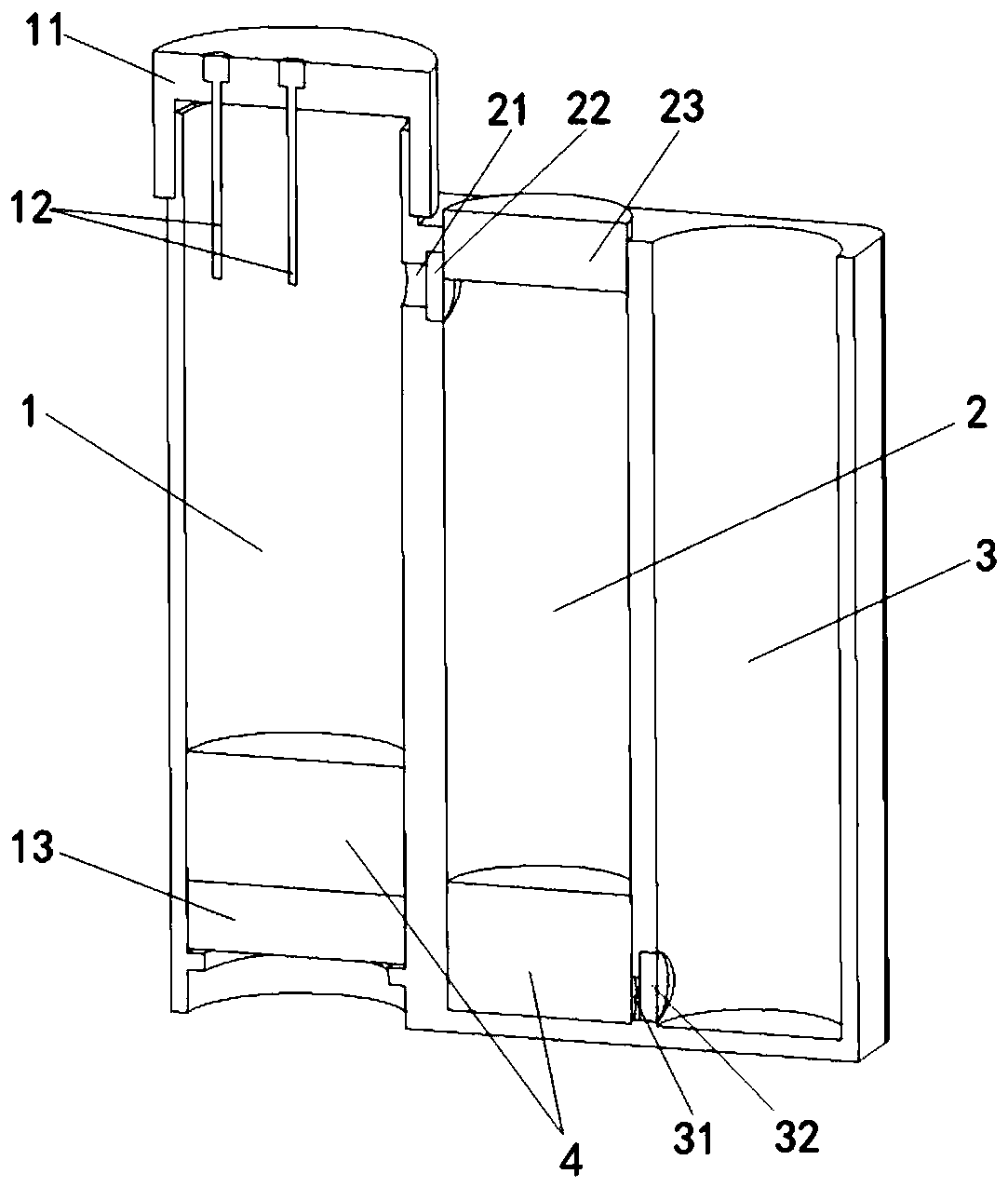

[0078] A sample pretreatment device that automatically recognizes the liquid level, such as figure 1 As shown, the main pipe 1 made of polypropylene material, the primary pipe 2 and the secondary pipe 3 are connected in parallel, the distance between the main pipe 1 and the primary pipe 2, the primary pipe 2 and the secondary pipe 3 A through hole is provided; the top of the main pipe 1 is covered with a top cover 11 on which an electrode 12 is connected; the bottom of the main pipe 1 is connected with a piston 13 .

[0079] The main pipe 1 is a hollow cylindrical structure, and the hollow interior is also a cylindrical structure with a vertical axis and an inner diameter of 5 cm. The top of the main pipe 1 is covered with a top cover 11 (polypropylene material). The top cover 11 is a cylindrical groove structure with an open end, the opening is vertically downward, and the thickness of the bottom surface of the groove is 5mm. Bottom abutment. Two independent and parallel el...

Embodiment 2

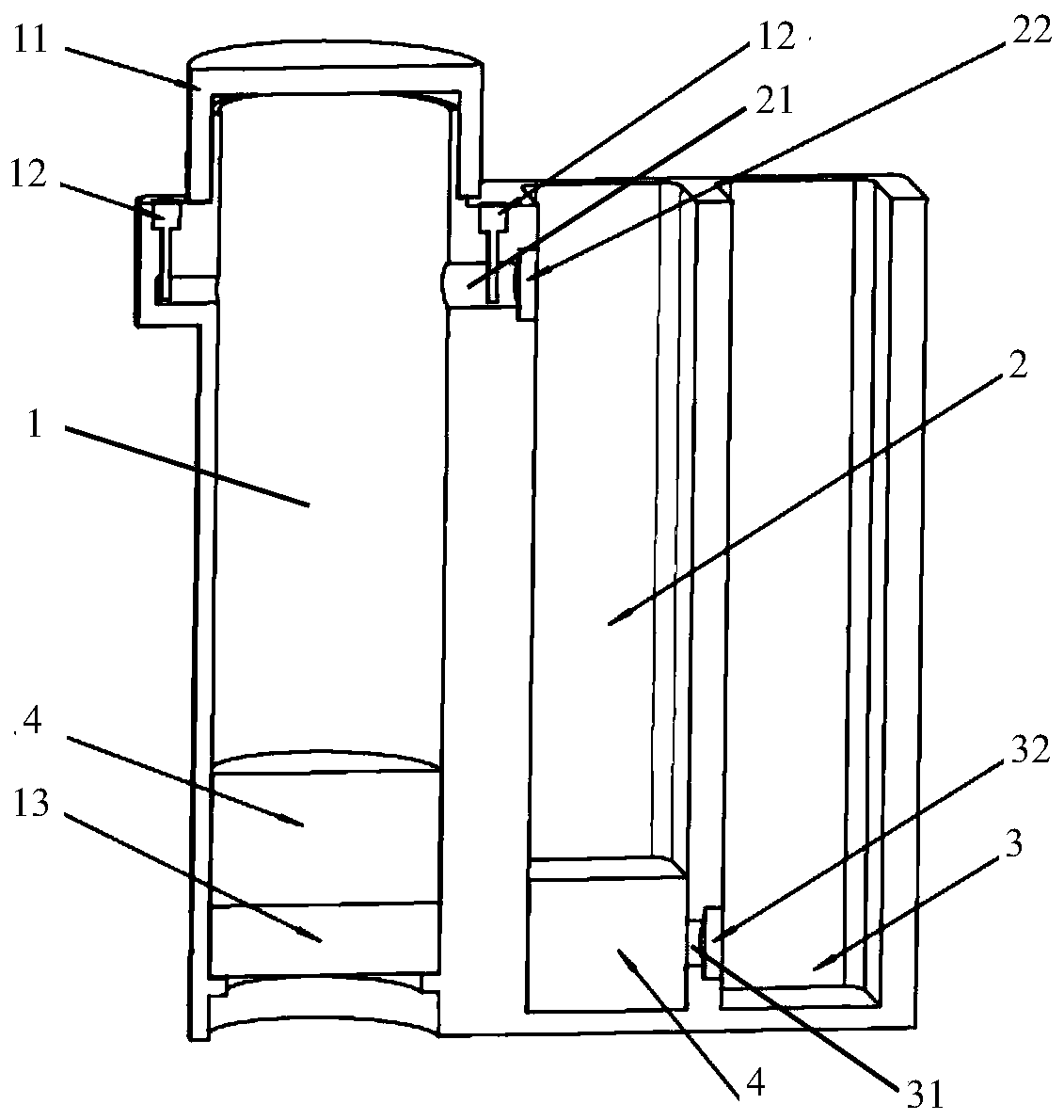

[0086] A sample pretreatment device that automatically recognizes the liquid level, such as figure 2 Shown, the difference with embodiment 1 is:

[0087] (1) Two wire electrodes 12 are respectively located on both sides of the pipe wall of the main pipe 1, and can be in contact with the solution in the main pipe 1. One of the wire electrodes 12 is inserted in the first through hole 21, and the other wire electrode 12 is inserted into the first through hole 21. Located in the side wall of the main pipe 1 opposite to the first through hole 21, the lengths of the two wire electrodes 12 are both 10 mm;

[0088] (2) the inner diameter of the main pipe 1 is 4cm, the groove bottom surface thickness of the top cover 11 is 3mm, the peripheral length of the first-level attached pipe 2 and the second-level attached pipe 3 is 2cm, and 200mg C18, 150mgPSA, 50mg graphitized carbon adsorbent.

[0089] Except above-mentioned difference, the structure of all the other parts and connection r...

Embodiment 3

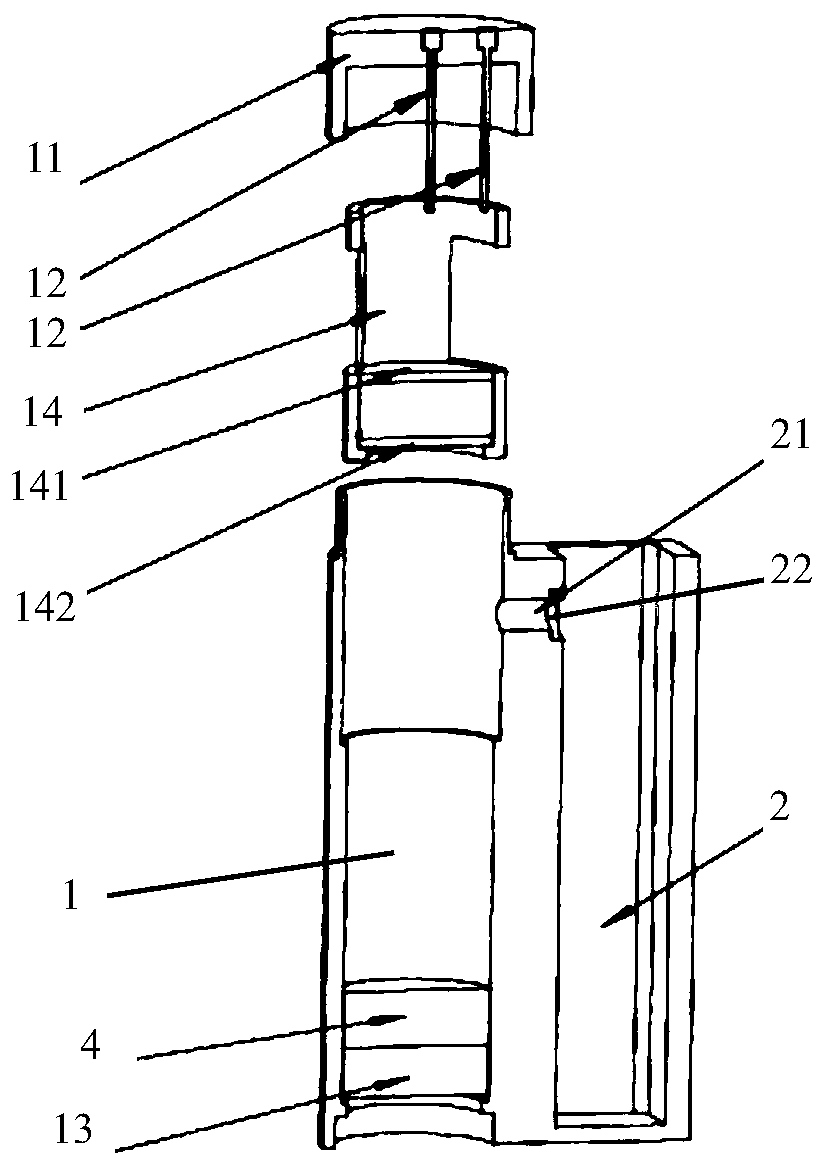

[0092] A sample pretreatment device that automatically recognizes the liquid level, such as image 3 As shown, the main pipe 1 made of polypropylene material and the first-stage attached pipe 2 are connected in parallel, and a first through hole 21 is arranged between the main pipe 1 and the first-stage attached pipe 2; the top of the main pipe 1 is covered with a top cover 11, and the top An electrode 12 is connected to the cover 11 ; an inner plug 14 is arranged under the top cover 11 , and a piston 13 is connected to the bottom of the main pipe 1 .

[0093] The main pipe 1 is a hollow cylindrical structure, and the hollow interior is also a cylindrical structure with a vertical axis and an inner diameter of 3 cm. The top of the main pipe 1 is covered with a top cover 11. The top cover 11 is a cylindrical groove structure with one end open. The opening is vertically downward. Two independent and parallel electrodes 12 are vertically disposed on the top surface of the top co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com