Withstand voltage detection device for high-performance electrical copper wire and working method of device

A technology of withstand voltage detection and detection device, which is applied in the direction of measurement device and application of stable tension/pressure to test the strength and strength characteristics of materials, can solve the problems of continuous detection of copper wires, etc., and achieves easy operation and working principle. Simple, increased frequency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

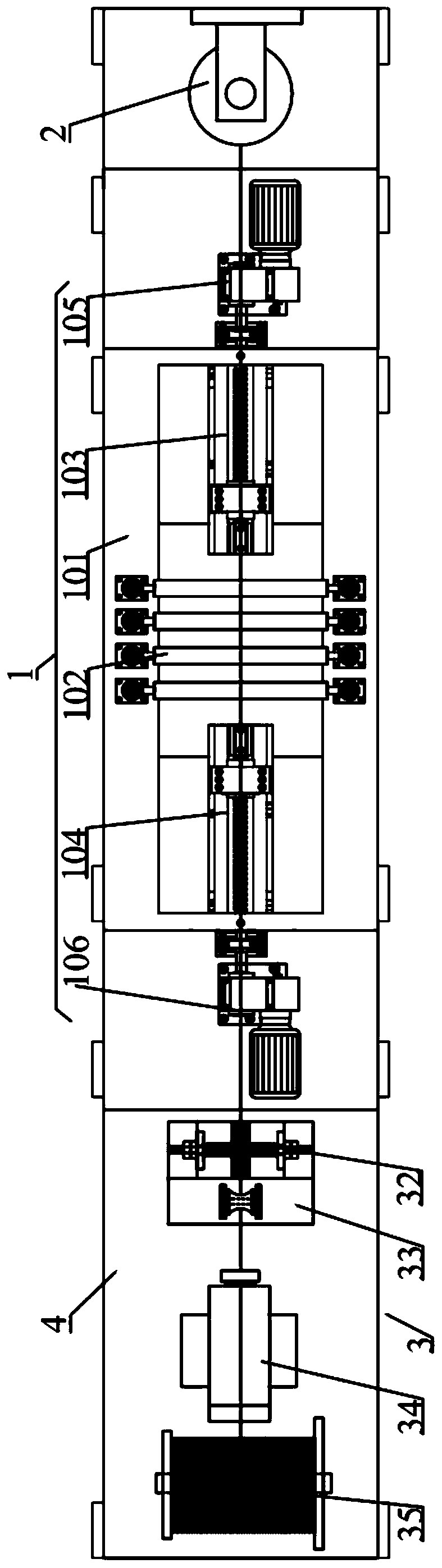

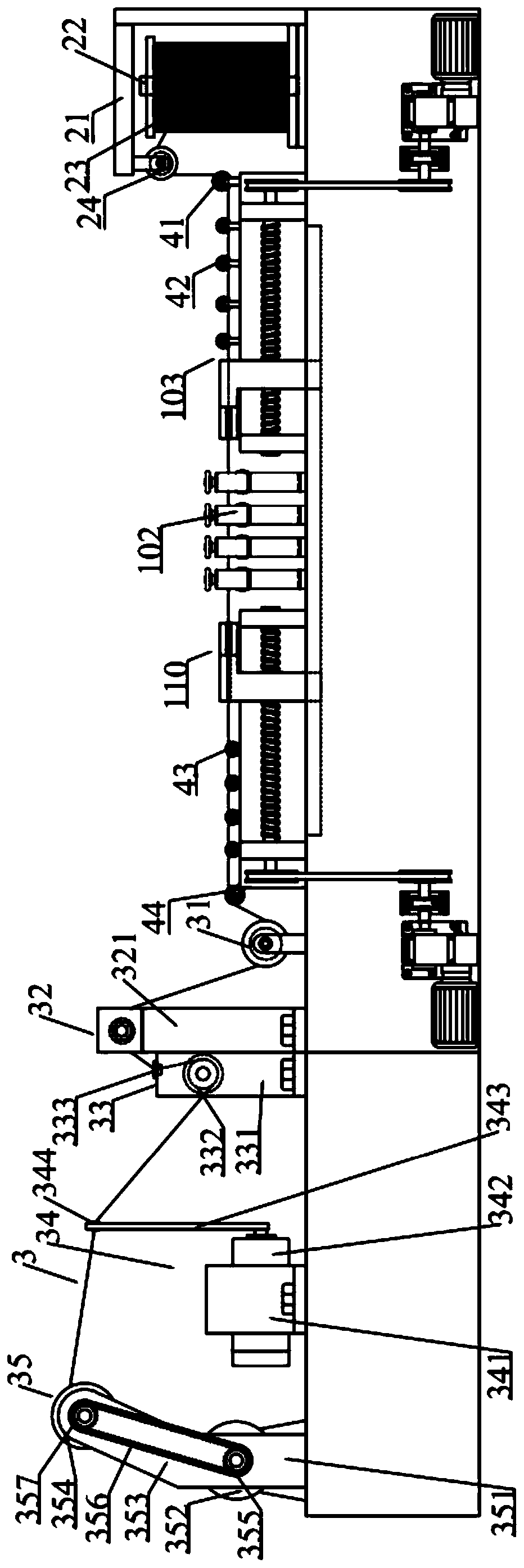

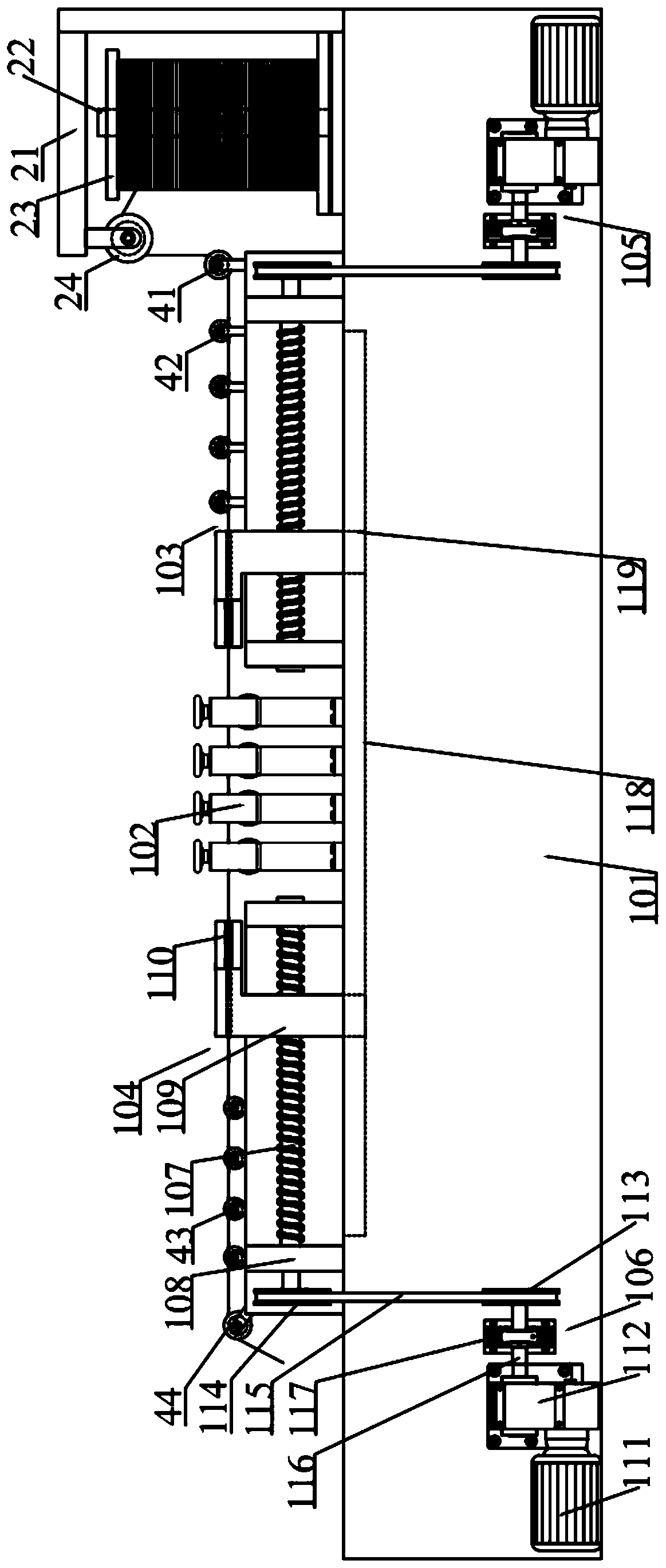

[0042] like figure 1 , 2 The shown high-performance electrical copper wire withstand voltage detection device includes a copper wire tension test assembly 1, a copper wire pay-off assembly 2, a copper wire winding assembly 3 and a detection device support platform 4. The copper wire tension test Component 1, copper wire pay-off component 2 and copper wire winding component 3 are all fixedly arranged on the upper end surface of the detection device support platform 4, and copper wire pay-off component 2, copper wire tension test component 1 and copper wire winding The components 3 are arranged in sequence according to the conveying direction of the copper wires.

[0043] like image 3 The copper wire tension test assembly 1 shown includes a test platform 101, a group of copper wire support assemblies 102, a copper wire pressing assembly 103, a copper wire pressing assembly 2 104, a tension driving assembly 105 and a tension driving assembly Two 106, the copper wire supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com