Pinch roll oil-seal-free speed reducer for steel industry

A technology of pinch rollers and reducers, which is applied in the direction of mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problems of easy aging, affecting sealing performance and service life, dust ingress, etc., to avoid high temperature aging, Good sealing and dustproof effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further description will be made below in conjunction with drawings and embodiments.

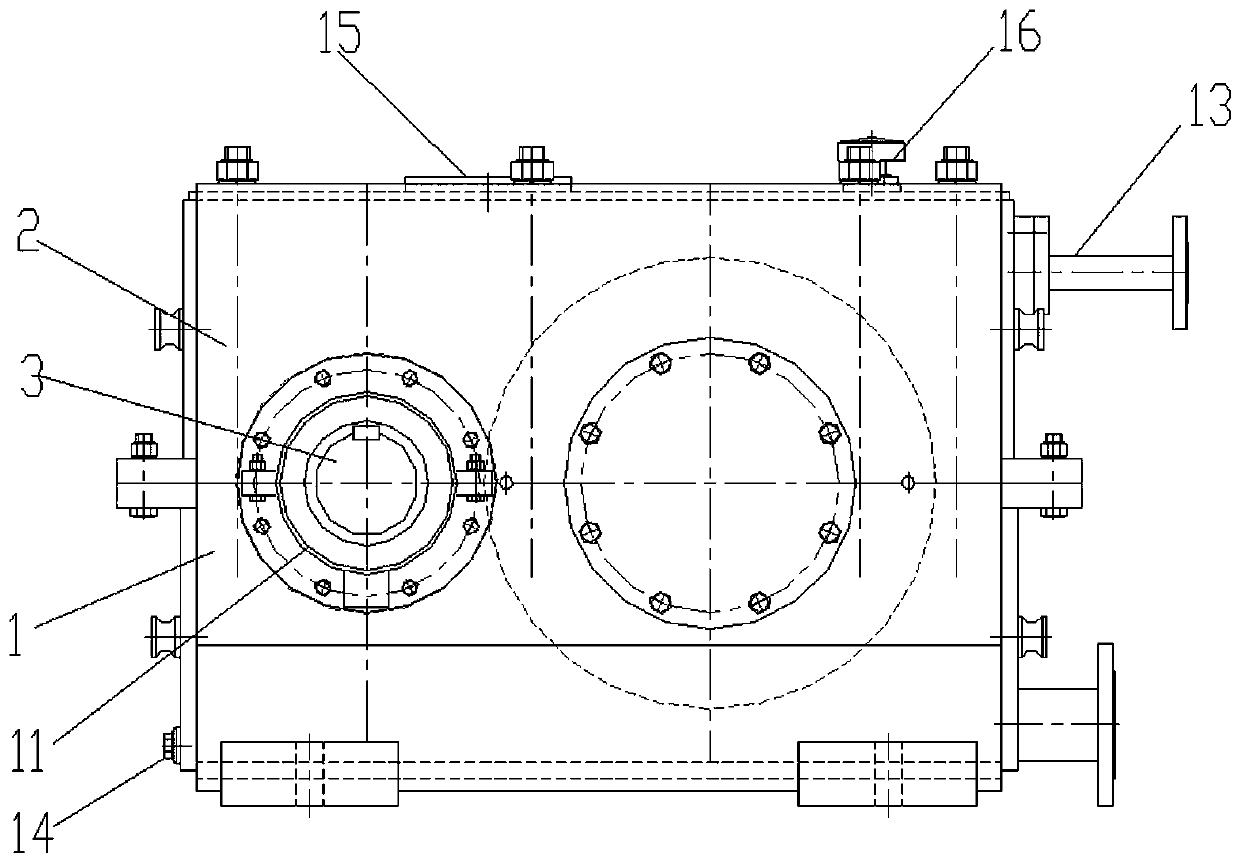

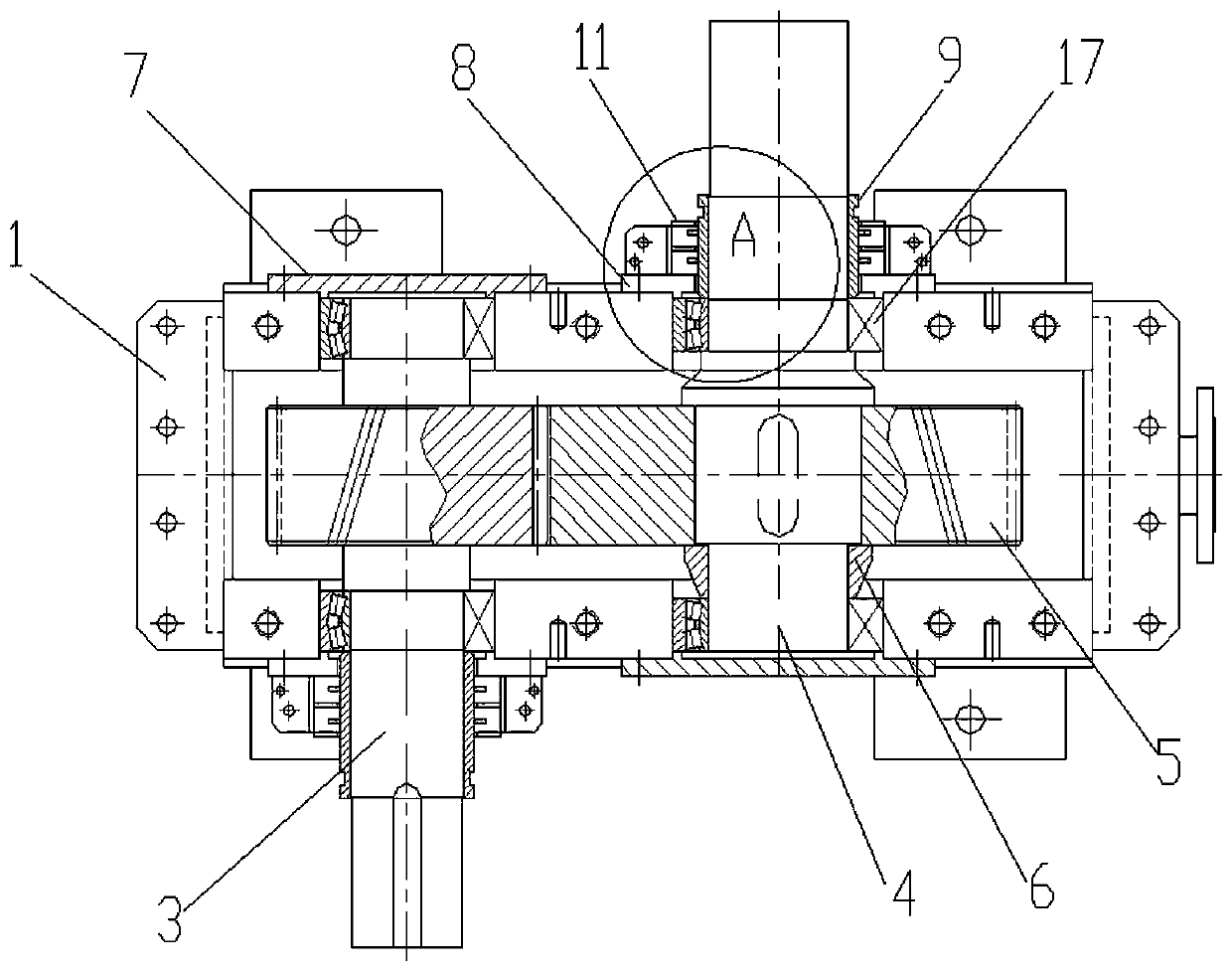

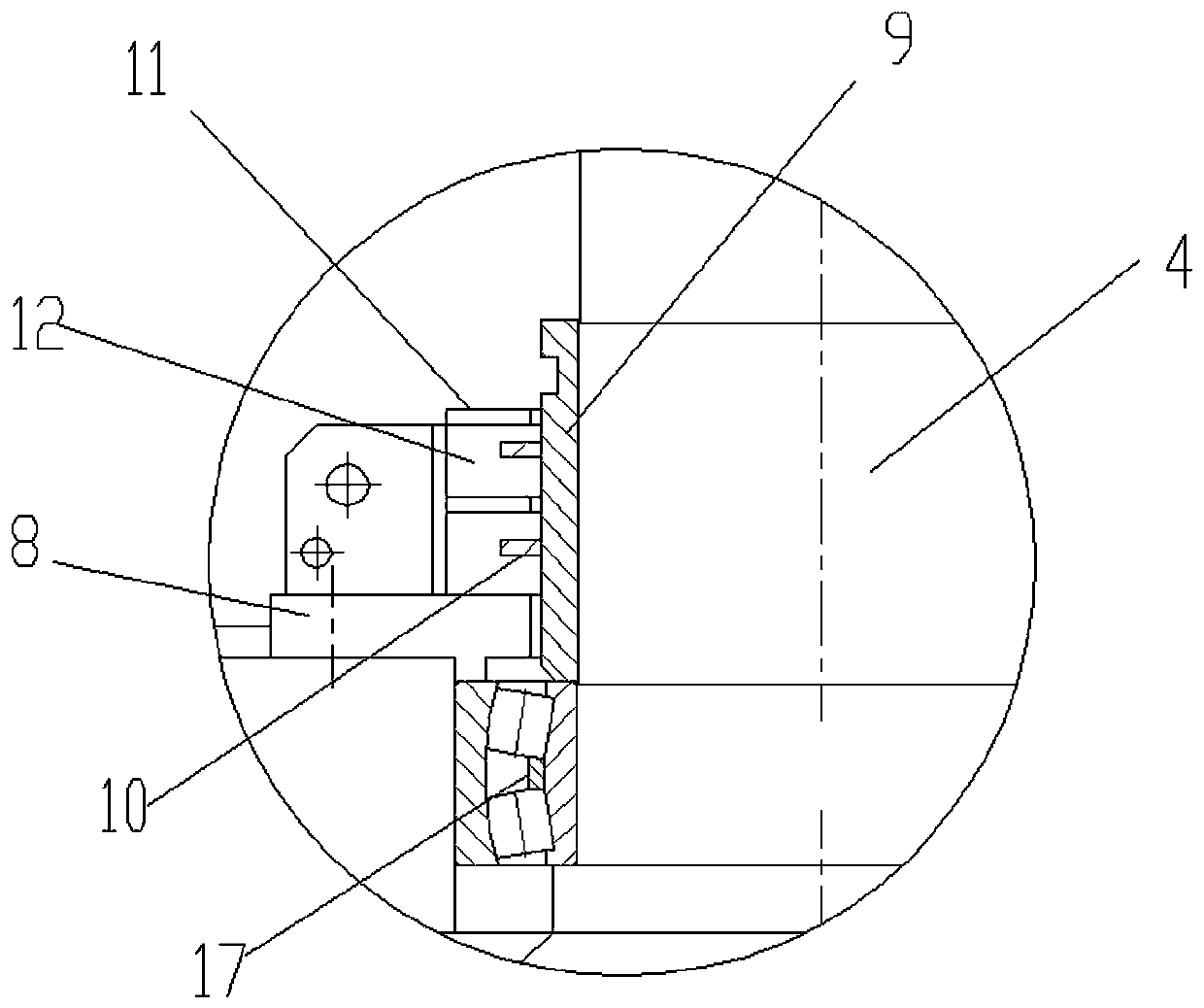

[0017] figure 1 , 2 , 3 shows: an oil-seal-free reducer for pinch rollers in the iron and steel industry includes a box body 1, a box cover 2, an input shaft 3, an output shaft 4, a gear 5, a spacer ring 6, a stuffy cover 7, and a transparent cover 8 , Oil throwing ring 9, oil throwing ring sheet 10, semicircular oil throwing shell 11, inlet / release pipeline 13, screw plug 14, sight hole cover 15, ventilation cover 16. The input shaft 3 and the output shaft 4 protrude from the box body 1 in opposite directions and are covered by the box cover 2. One end of the input shaft 3 is encapsulated by the stuffy cover 7, and the other end penetrates the through cover 8, and the input shaft is crimped on the box body through the cover. The supporting bearing 17, the oil throwing ring 9 is sleeved on the input shaft outside the supporting bearing, and more than two oil throwing ring pieces 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com