Method for calculating tooth surface wear of double circular arc harmonic reducer

A technology of harmonic reducer and calculation method, applied in the direction of calculation, computer-aided design, design optimization/simulation, etc., can solve the problems of the complexity of wear mechanism, restricting the reliability of harmonic reducer, and difficult to determine the load distribution law, etc. achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

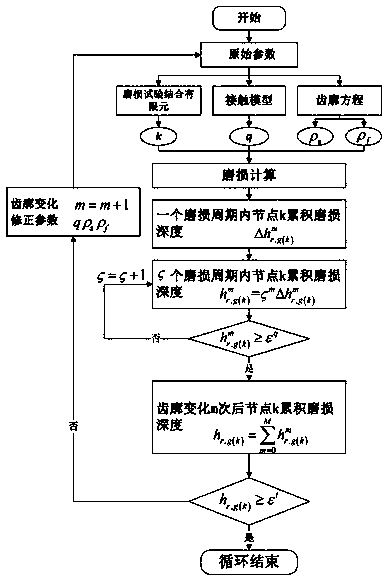

[0024] Such as figure 1 The calculation method of the present invention shown is as follows:

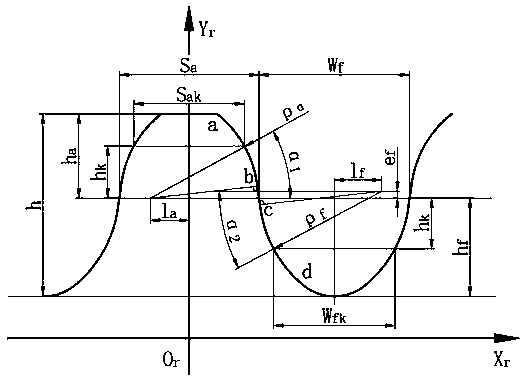

[0025] The establishment of the tooth profile equations of the flexible gear and the rigid gear of the double-arc harmonic reducer: the harmonic reducer adopts a special double-arc tooth shape, and the double-arc tooth shape is composed of arcs at both ends and a straight line, such as figure 2 Shown is a schematic diagram of a double-arc tooth profile. According to the basic parameters of the tooth surface, the tooth profile equation of the flexspline is constructed. In order to consider the influence of the elastic deformation of the flexspline on the conjugate motion, the envelope method is used to solve the tooth profile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com