Device capable of conveniently drilling holes in fractured rock mass and drilling method thereof

A rock mass, convenient technology, applied in the direction of drilling equipment and methods, earthwork drilling, drill pipe, etc., can solve the problems of difficult to meet high quality standards, low construction efficiency, inconvenient construction, etc., to save construction materials and increase construction time , time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

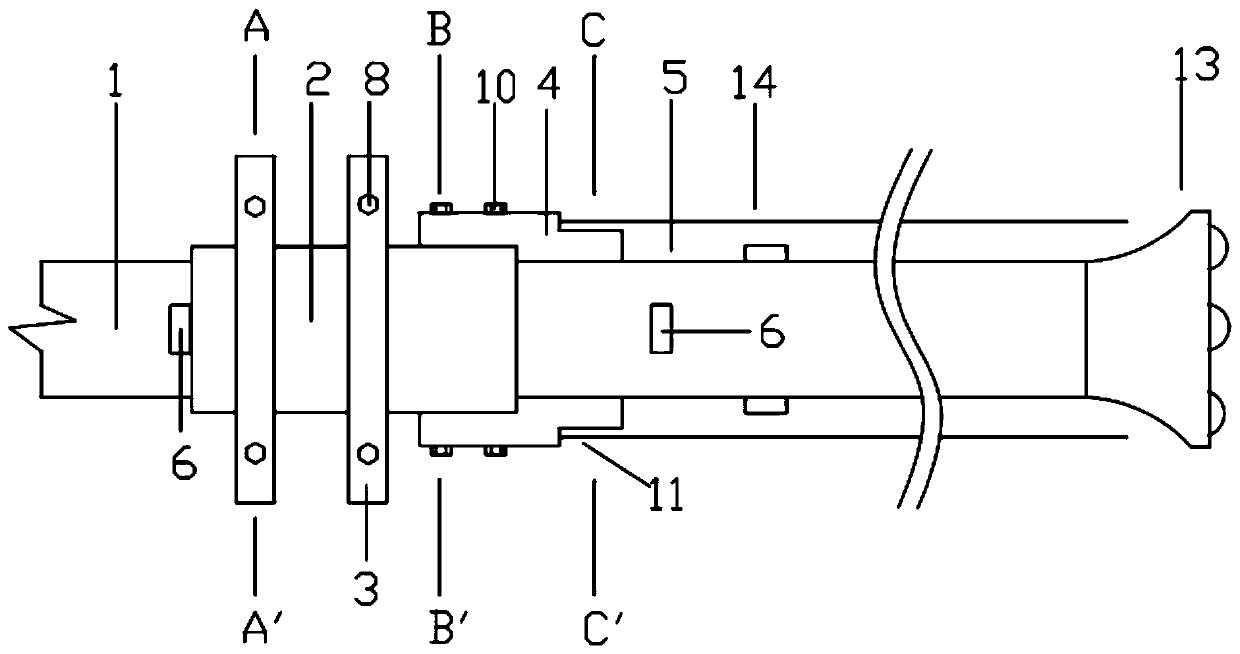

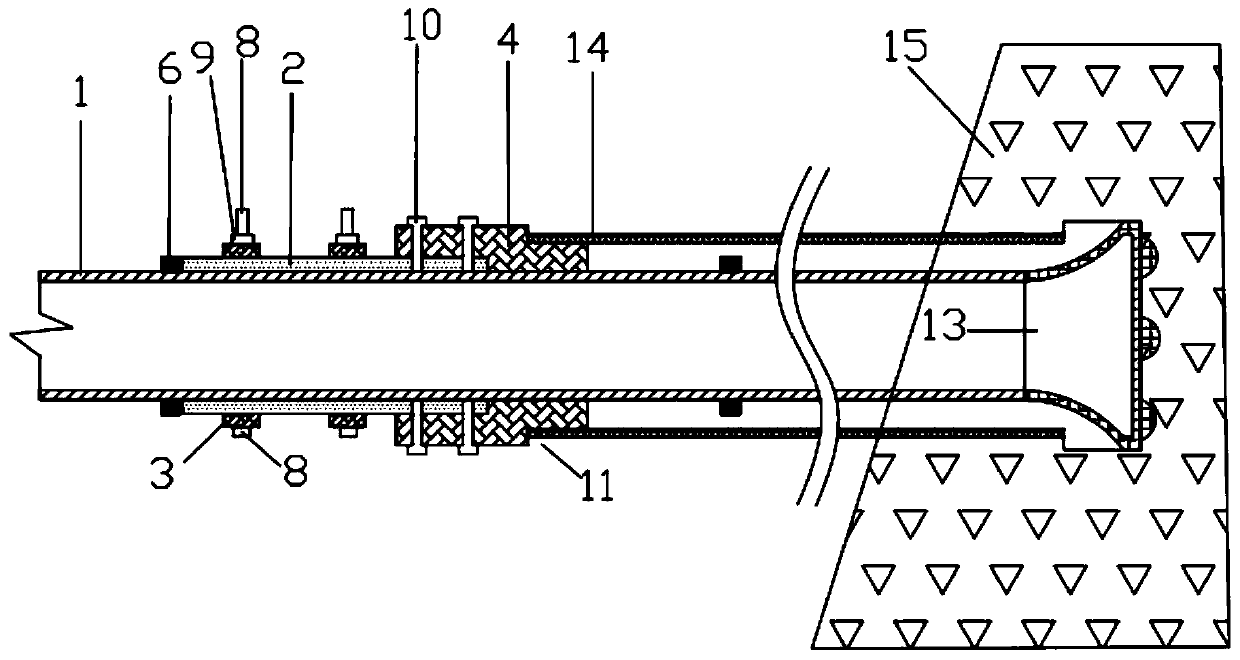

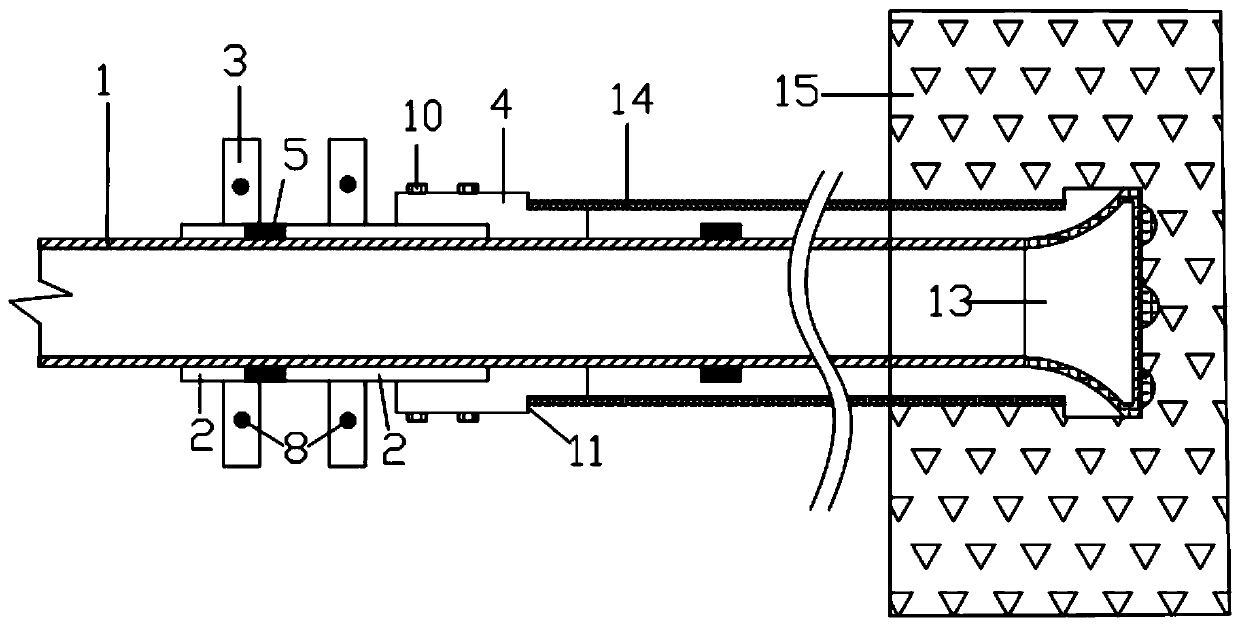

[0045] As a specific embodiment provided by the present invention, preferably, the locking mechanism includes 2 sets, and each set includes 2 fixing rods 3, and 2 screw rods 8 and nuts 9 connect the 2 screw rods 8 and 9 through the screw holes on the fixing rod 3. The small semicircular chuck 2 is locked.

[0046] As a specific embodiment provided by the present invention, preferably, the two fixing rods 3 are respectively welded to the two small semicircular chucks 2 .

[0047] As a specific embodiment provided by the present invention, preferably, the rotation limiting protrusion 5 and the axial limiting protrusion 6 form a set of limiting structures, and more than two sets of upper limiting structures are arranged on the drill pipe 1 .

[0048] As a specific implementation mode provided by the present invention, it will be described in detail below.

[0049] The invention is suitable for follow-up of wall casing when drilling in broken rock body, prevents surrounding rock ...

Embodiment 1

[0059] Embodiment 1: as a kind of specific embodiment provided by the present invention, a kind of method for the device drilling that facilitates drilling in broken rock mass as described above is characterized in that, comprises the following steps:

[0060] Step 001: The drilling rig is in place, and the drill pipe assembly with follow-up wall casing is installed;

[0061] Step 002: While opening a hole in the broken rock mass, the wall casing is pushed up by the shoulder at the hole, and the wall is drilled;

[0062] Step 003: When the wall casing follows up to the hole, lift the drill pipe and drill bit out of the hole, and connect the wall casing and drill pipe length;

[0063] Step 004: Continue to drill holes, and the retaining casing continues to follow the retaining wall until it penetrates the broken rock mass and drills to a complete rock mass;

[0064] Step 005: Lift the drill pipe, remove the drill pipe assembly and eccentric drill bit with follow-up wall casing...

Embodiment 2

[0065] Embodiment 2: A method of drilling in a broken rock body. The difference from Embodiment 1 is that the hole is drilled at a complete slope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com