Method for processing steering front axle of underground tank car

A processing method and technology of the front axle, which can be used in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., and can solve the problems of difficult processing and the length of the whole bridge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings and embodiments.

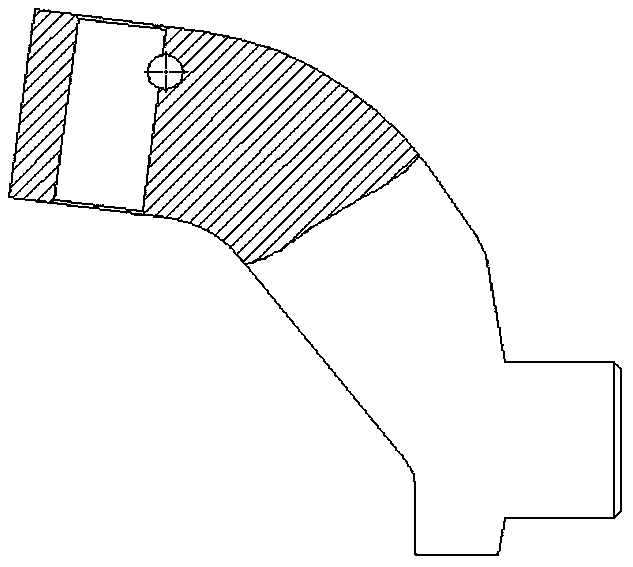

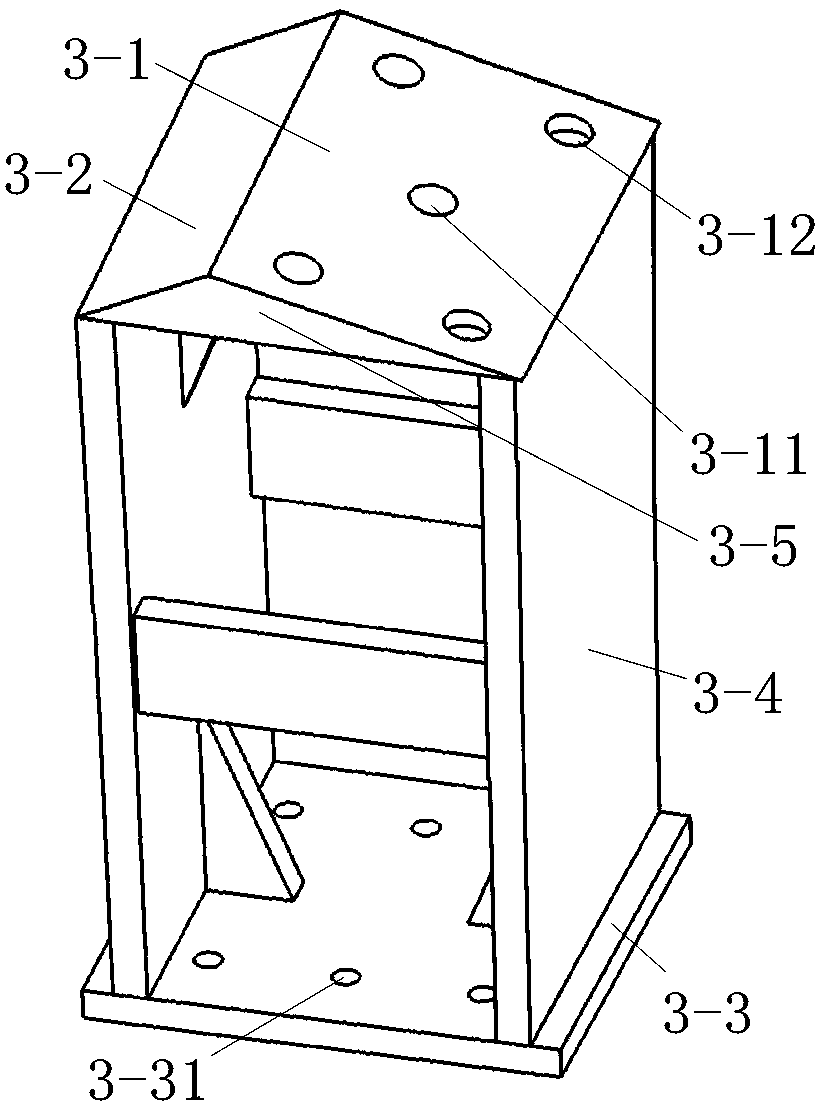

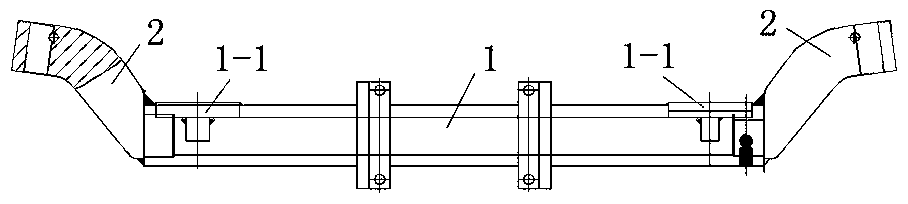

[0022] Such as Figure 1 to Figure 4 As shown, a processing method for steering the front axle of an underground tanker uses self-designed positioning tool 3 for auxiliary processing. The positioning tool 3 includes a bottom plate 3-3, and side plates 3-4 are vertically fixed on both sides of the bottom plate 3-3. , the top of the side plates 3-4 on both sides of the bottom plate 3-3 is provided with a top plate 3-5, and one side of the top plate 3-5 is obliquely upwardly provided with an angle of 7.5° towards the center of the top plate 3-5 from the side edge. Inclined surface I3-1, the side of the higher side of the inclined surface I3-1 or the side close to the higher side of the inclined surface I3-1 is provided with an inclined surface II3 obliquely downward in the direction away from the inclined surface I3-1 -2, the inclined surface II3-2 runs through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com