Internal combustion engine cooling system, control method and vehicle

A cooling system and internal combustion engine technology, applied in the field of vehicles, can solve the problems of reducing the life of the internal combustion engine, large deformation of the cylinder block, and uneven temperature, so as to prevent excessive deformation, avoid uneven shrinkage, and improve heat dissipation energy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

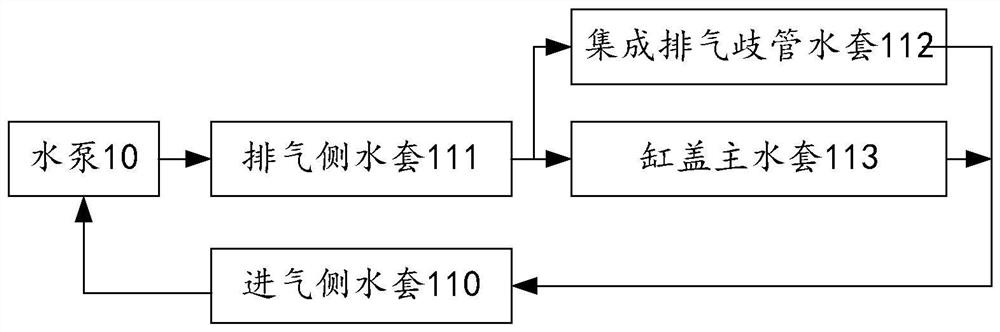

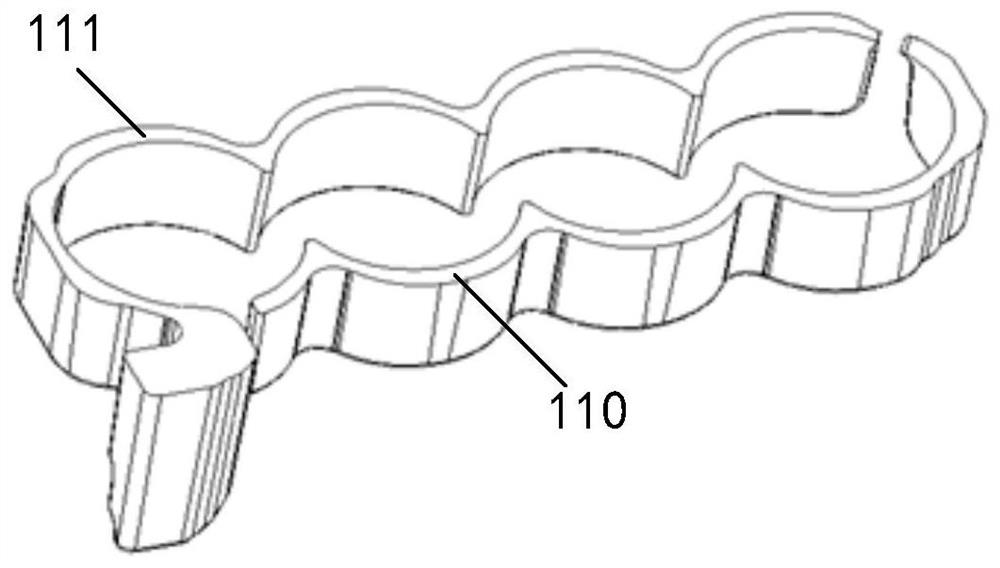

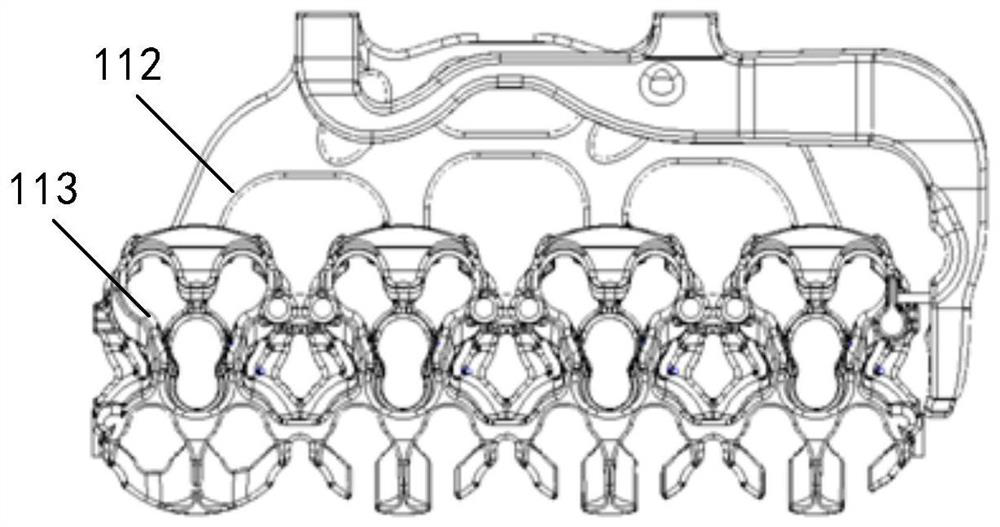

[0046] refer to Figure 1 to Figure 2-2 , provides a schematic diagram of the principle of an internal combustion engine cooling system of the present invention, the internal combustion engine cooling system includes a water pump 10 and an internal combustion engine cylinder block, and the internal combustion engine cylinder block is provided with an intake side water jacket 110 and an exhaust side water jacket 111 , Integrated exhaust manifold water jacket 112 and cylinder head main water jacket 113;

[0047] The water outlet of the water pump 10 is connected to the exhaust side water jacket 111, and the coolant is pumped to the exhaust side water jacket 111 by the water pump 10 for cooling the exhaust side of the cylinder block ;

[0048] The exhaust side water jacket 111 is connected to the cylinder head main water jacket 113 and the integrated exhaust manifold water jacket 112 at the same time, and the cylinder head main water jacket 113 is connected to the integrated exh...

Embodiment 2

[0053] refer to image 3 , diagram 2-1 and Figure 2-2 , provides a schematic diagram of the principle of an internal combustion engine cooling system of the present invention, the internal combustion engine cooling system includes a water pump 10 and an internal combustion engine cylinder block, and the internal combustion engine cylinder block is provided with an intake side water jacket 110 and an exhaust side water jacket 111 , Integrated exhaust manifold water jacket 112 and cylinder head main water jacket 113;

[0054] The water outlet of the water pump 10 is connected to the exhaust-side water jacket 111, and the coolant is pumped to the exhaust-side water jacket 111 by the water pump 10 for cooling the exhaust side of the cylinder block;

[0055] The exhaust side water jacket 111 is connected to the cylinder head main water jacket 113 and the integrated exhaust manifold water jacket 112 at the same time, and the cylinder head main water jacket 113 is connected to th...

Embodiment 3

[0069] refer to Figure 4 , the present invention provides a cooling control method for an internal combustion engine, the method comprising:

[0070] Step 101, pump the coolant to the water jacket on the exhaust side through the water pump to cool the exhaust side of the cylinder block;

[0071] Step 102, the coolant in the water jacket on the exhaust side enters the main water jacket of the cylinder head and the water jacket of the integrated exhaust manifold respectively in two routes according to a preset ratio, and is used to cool the cylinder head and the integrated exhaust manifold respectively. tube cooling;

[0072] Step 103 , the coolant in the cylinder head main water jacket and the integrated exhaust manifold water jacket converges into the intake side water jacket for cooling the intake side of the cylinder block.

[0073] A cooling method for an internal combustion engine according to the present invention is based on the aforementioned internal combustion engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com