Microwave sintering and drafting device for pasty polytetrafluoroethylene extruded fibers

A polytetrafluoroethylene and microwave sintering technology, applied in the direction of drawing spinning, artificial filament heat treatment, etc., can solve the problems of uneven thermal shrinkage of fibers, slow heating speed, high energy consumption, and achieve uniform temperature distribution and temperature rise. The effect of fast speed and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

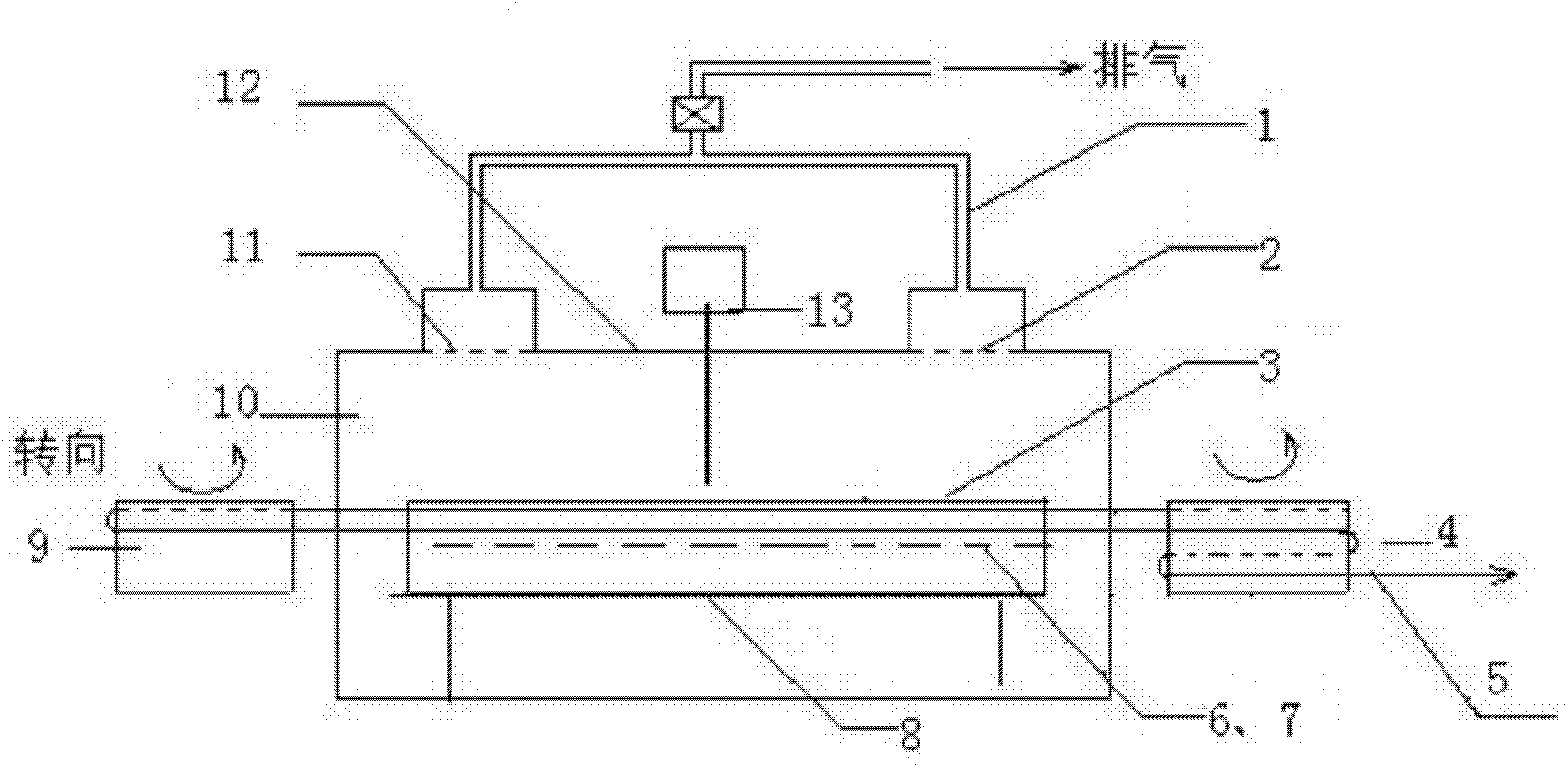

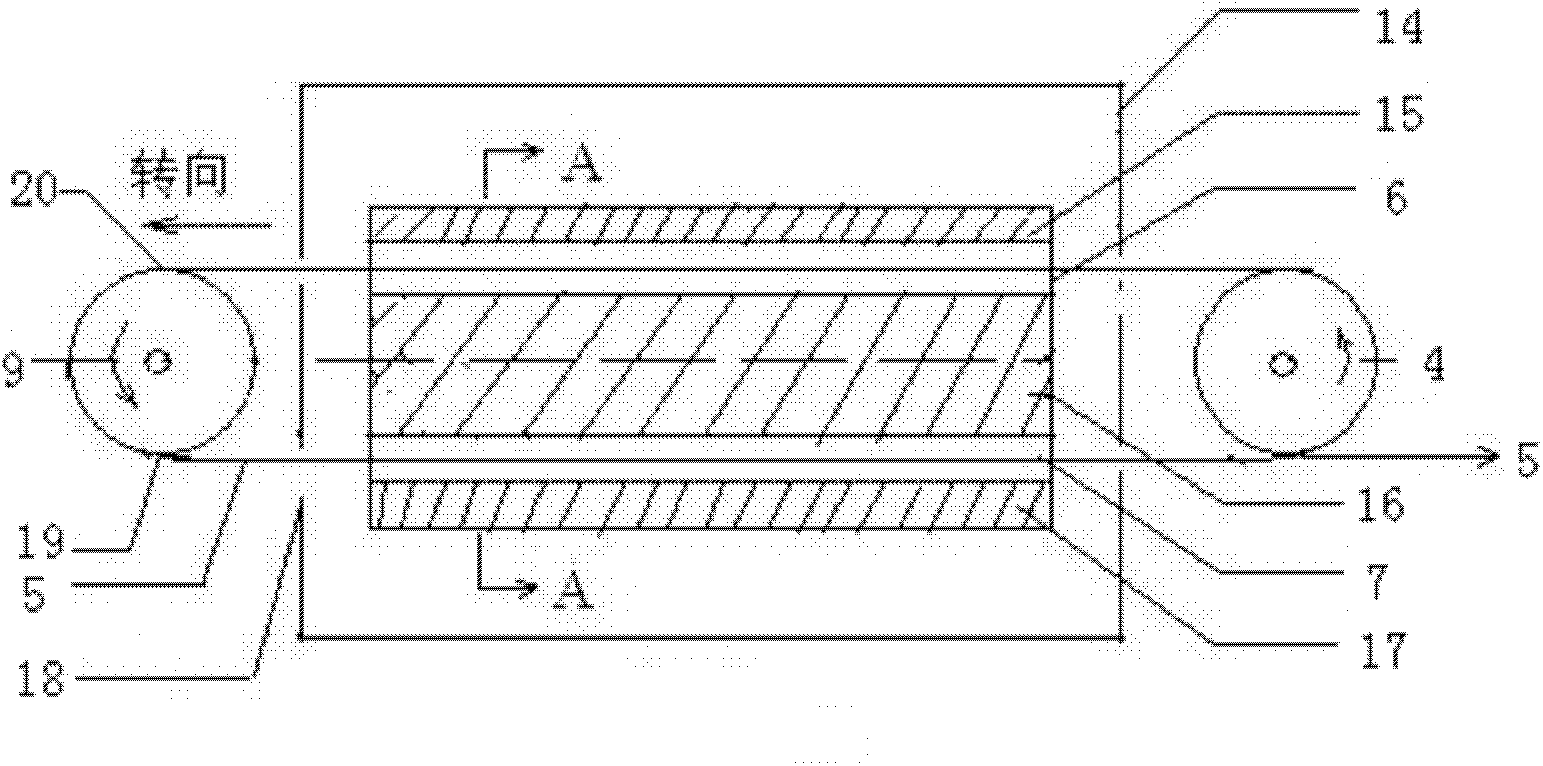

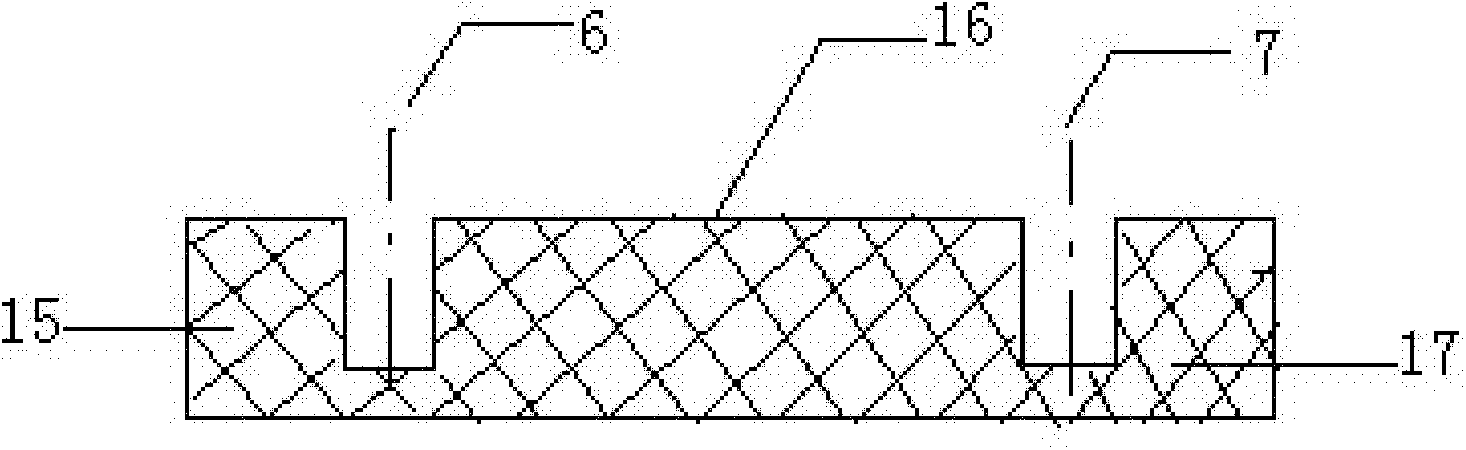

[0017] The present invention includes a microwave heating system, a sintering device 3 , a temperature measurement system and a control system 13 , a transmission system and an exhaust system 1 . Wherein, the microwave heating system includes a microwave heating chamber and a microwave generator, and the microwave generator is an existing technology. The microwave heating chamber includes a microwave heating chamber bottom 14, a microwave heating chamber side 10 and a microwave heating chamber top 12, and the There are fiber inlet and outlet ports 18, and the top 12 of the microwave heating cavity is provided with an exhaust hole with an aperture smaller than the microwave wavelength. The microwave generator is composed of 3 to 5 magnetrons with adjustable heating power, and its frequency is 915MHZ, or 2450MHZ are all available; the temperature measurement system is composed of infrared temperature measurement instruments, which are existing technologies and are located at the ...

Embodiment 2

[0020] During work, the linear velocity of the main drive wheel 4 can be set to be 3 to 4 times that of the slave drive wheel 9 . The polytetrafluoroethylene fiber guide port 18 is introduced, and after passing through the guide port 18 and the sintering tank 6 of the sintering device, winding from the rotating wheel 9, and then introduced by another guide port 18, and passing through another sintering tank 7 and then winding the main Rotate wheel 4 and lead to drafting process. Set the microwave heating temperature to 380°C and the heating rate to 60°C / min, start the microwave heating system to start heating the medium (15, 16, 17), and start the main drive wheel 4 and exhaust system 1 at the same time to make the PTFE Vinyl fibers are sintered slowly through the sintering tanks (6, 7) and stretched 3 to 4 times. Correspondingly, the temperature measurement system and the control system 13 installed on the top of the cavity simultaneously measure the temperature of the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com