Laser cutting device and method for controlling plasma through electromagnetic field to regulate and control crack expansion

A laser cutting and plasma technology, applied in laser welding equipment, circuits, manufacturing tools, etc., can solve the problems of laser stealth cutting efficiency not meeting relevant requirements, expansion of wafer damage area, etc., to achieve good cross-sectional flatness, cutting The effect of improved efficiency and improved flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

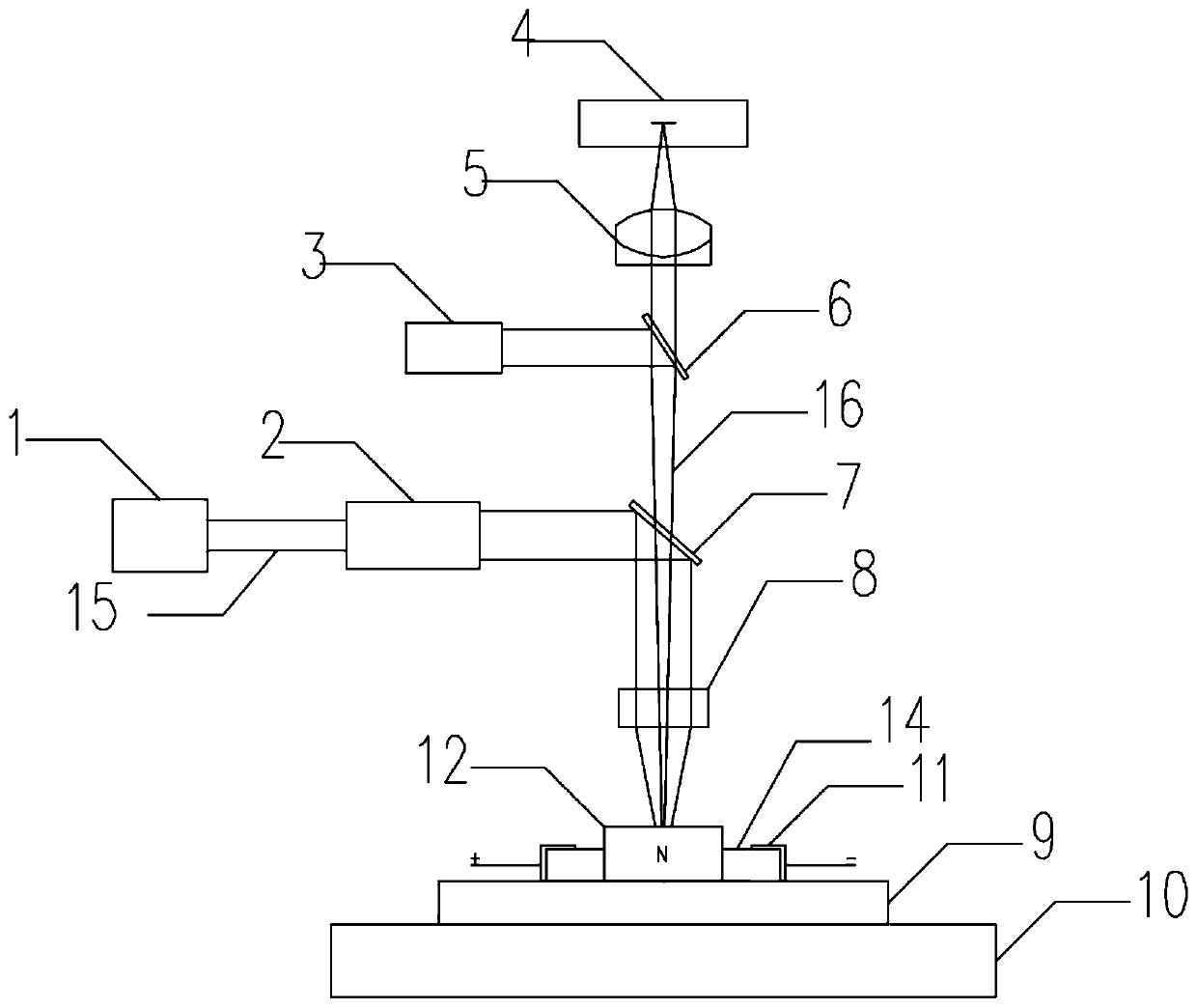

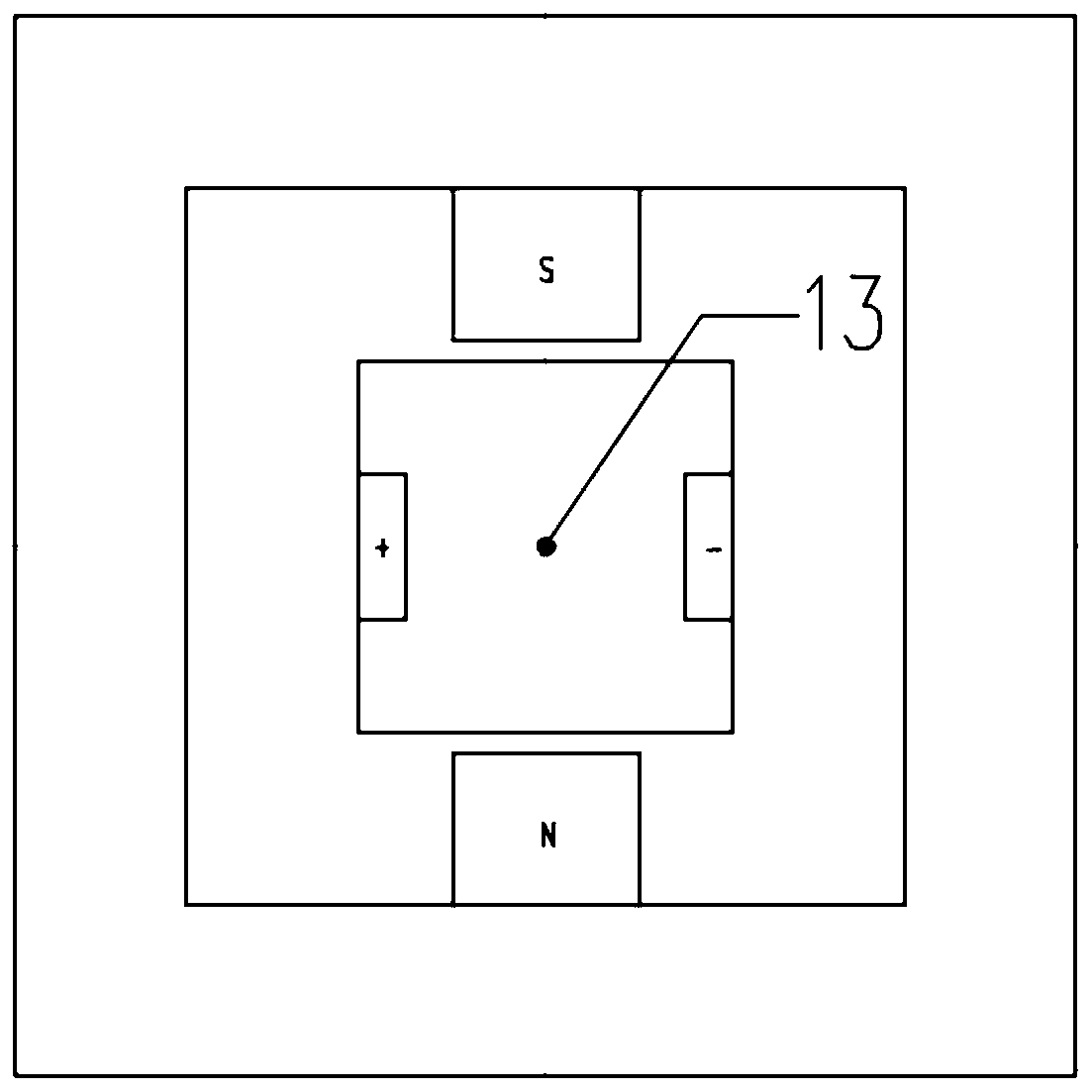

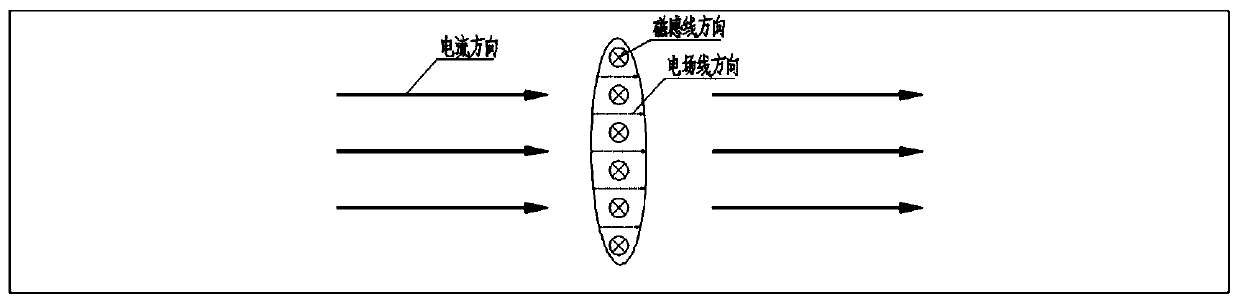

[0044] The laser cutting device for controlling crack propagation by electromagnetic field control plasma includes: a multi-axis mobile platform 9; an imaging system for acquiring surface images of the workpiece 14 processed on the multi-axis mobile platform 9; an invisible cutting device for generating laser beams 15, laser beams 15 converges to the inside of the workpiece 14 to be processed to form a high-energy stealth cutting laser focal spot 13. The workpiece material at the focal spot absorbs energy and then vaporizes and ionizes to form plasma, which expands and impacts the material to form cracks; and the electromagnetic field generating device uses It is used to generate the electric field force and magnetic field force (Lorentz force) exerted on the plasma to make the plasma move. As a result, the plasma accelerates and further impacts the formed cracks to expand the cracks. By controlling the spatio-temporal position and field energy of the electromagnetic field, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com