Printed plate water cleaning structure and method

A printed board, board water technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as product damage, achieve the needs of cleaning, reduce impact, and reduce personnel. effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with embodiment; The following embodiment is not for the limitation of the present invention, only as the mode of supporting the realization of the present invention, any equivalent structural replacement within the technical framework disclosed in the present invention, all is the present invention. the scope of protection of the invention;

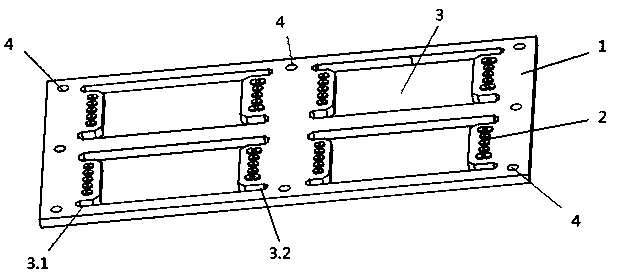

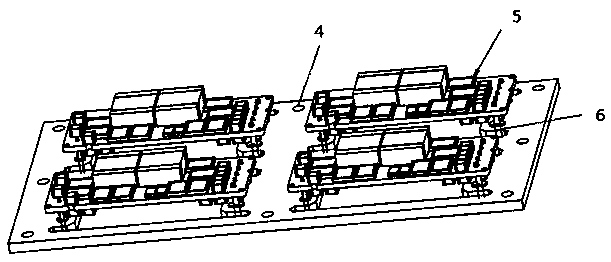

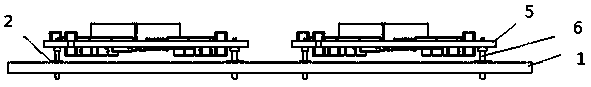

[0022] combined with figure 1 A printed board water cleaning structure described in , including a main body tray 1 of an electronic product, a plurality of rectangular slot holes 3 are arranged on the main body tray 1 of the electronic product, and fixing holes 2 are arranged at both ends of the rectangular slot hole 3 ; The two ends of the rectangular slot 3 are set to a "U"-shaped structure, forming an "I"-shaped slot; the two ends of the "I"-shaped slot are respectively provided with symmetrical thin slots 3.1 and thin slots 3.2. The main body tray 1 of the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com