Aluminum-loaded noble metal monolithic catalyst as well as preparation method and application thereof

A monolithic catalyst and precious metal technology, applied in the field of air purification, can solve the problems of cumbersome catalyst preparation process, high energy consumption in the preparation process, and restrictions on popularization and application, and achieve good market application value and promotion prospects, and the effect of low product and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Soak the metal aluminum honeycomb carrier with a length, width and height of 165×165×215mm and a mass of 66g in 0.5mol / L pickling solution for 20min, take it out and rinse it with water;

[0035] 2. Put the acid-washed metal aluminum honeycomb carrier into the precious metal precursor liquid (0.04mmol / L palladium chloride and 1mmol / L sodium chloride), and continue to react in a constant temperature water bath at 40°C for about 5 hours, then take it out and rinse with water clean;

[0036] 3. Dry the material obtained in step 2 at 100° C. to a constant weight to prepare a monolithic catalyst supported by metal aluminum and Pd metal.

[0037] This embodiment obtains that the mass content of noble metal Pd in the overall catalyst is 0.02%, and its catalytic combustion purification activity to toluene is at the reaction temperature T when the conversion rate of toluene is 10% and 90%. 10 = 192°C and T 90 = 261°C.

Embodiment 2

[0039] 1. Put the metal aluminum honeycomb carrier with a length, width and height of 165×165×215mm and a mass of 66g in 2.5mol / L pickling solution for 5 minutes, take it out and rinse it with water;

[0040] 2. Then put the pickled metal aluminum honeycomb carrier into the precious metal precursor liquid (0.10mmol / L palladium chloride and 2mmol / L ethylenediamine), and continue to react in a constant temperature water bath at 60°C for about 3 hours, then take out the water rinse off;

[0041] 3. Dry the material obtained in step 2 at 100° C. to a constant weight to prepare a monolithic catalyst supported by metal aluminum and Pd metal.

[0042] The mass content of noble metal Pd in the monolithic catalyst obtained in this embodiment is 0.05%, and its catalytic combustion purification activity to toluene is at the reaction temperature T when the conversion rate of toluene is 10% and 90%. 10 =186°C and T 90 = 252°C.

Embodiment 3

[0044] 1. Soak the metal aluminum honeycomb carrier with a length, width and height of 165×165×215mm and a mass of 66g in 1.5mol / L pickling solution for 10min, take it out and rinse it with water;

[0045] 2. Then put the pickled metal aluminum honeycomb carrier into the noble metal precursor liquid (0.21mmol / L palladium chloride and 3mmol / L sodium edetate), and continue to react in a constant temperature water bath at 70°C for about 3h Then remove and rinse with water;

[0046] 3. Dry the material obtained in step 2 at 100° C. to a constant weight to prepare a monolithic catalyst supported by metal aluminum and Pd metal.

[0047]The mass content of noble metal Pd in the monolithic catalyst obtained in this embodiment is 0.10%, and its catalytic combustion purification activity to toluene is at the reaction temperature T when the conversion rate of toluene is 10% and 90%. 10 = 183°C and T 90 = 229°C.

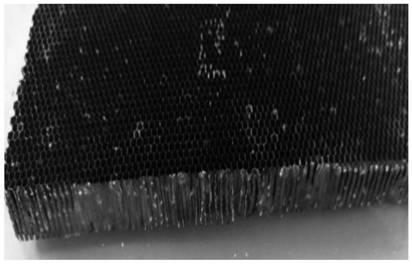

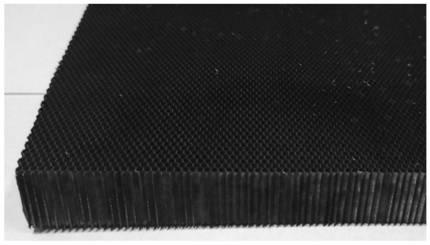

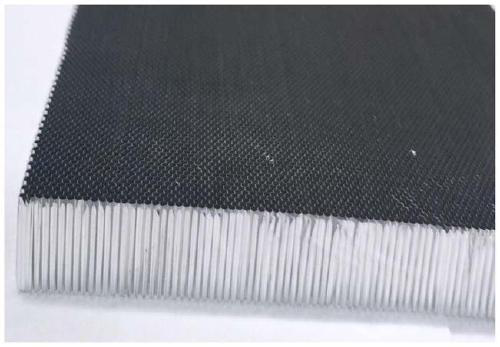

[0048] figure 1 with image 3 They are the physical picture and SEM ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com