Bright and clean x-ray source for x-ray based metrology

一种X射线、光源的技术,应用在巨大电流的X射线管、X射线管、X射线设备等方向,能够解决辐射低能量、限制利用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Reference will now be made in detail to prior art examples and some embodiments of the invention, examples of which are illustrated in the accompanying drawings.

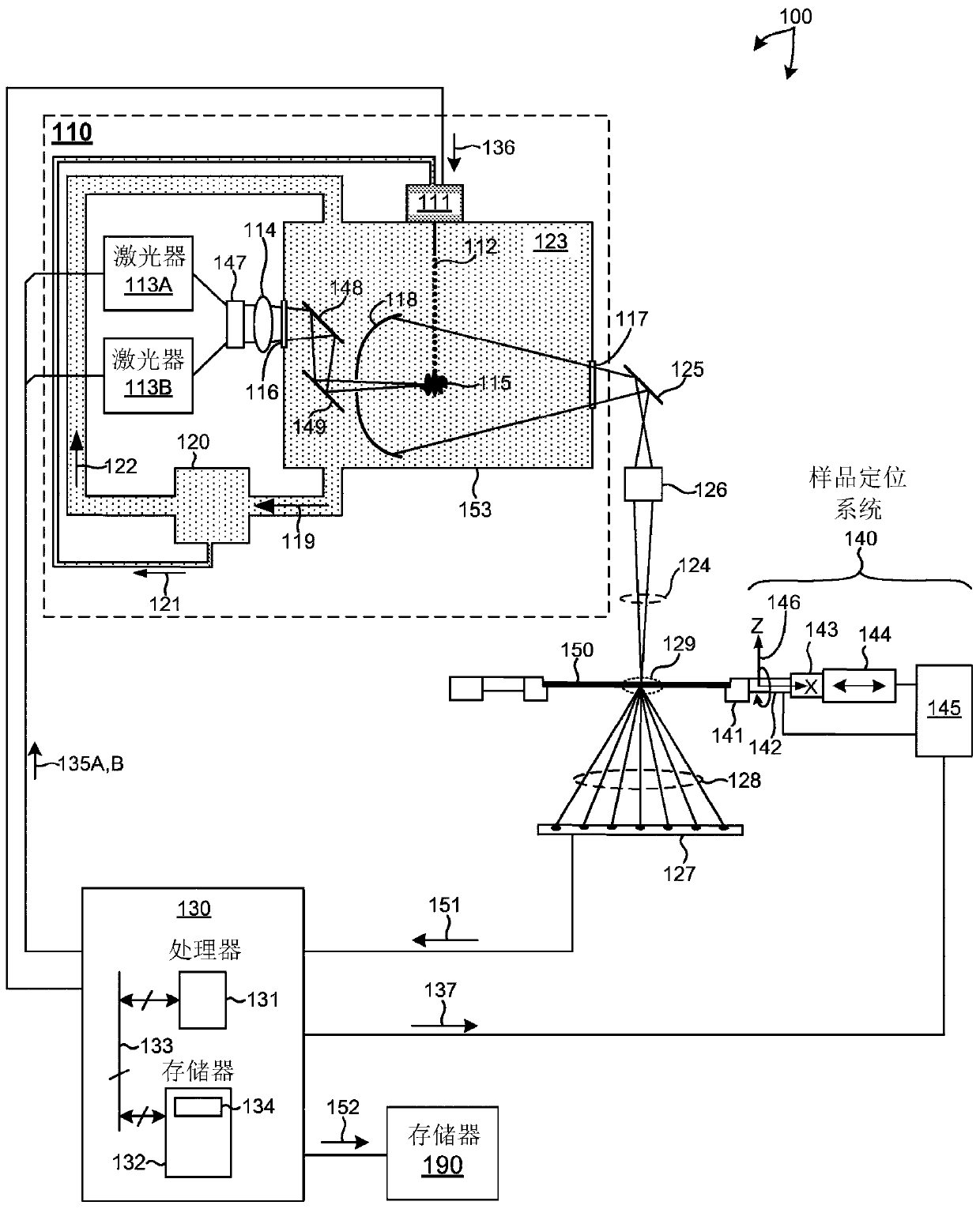

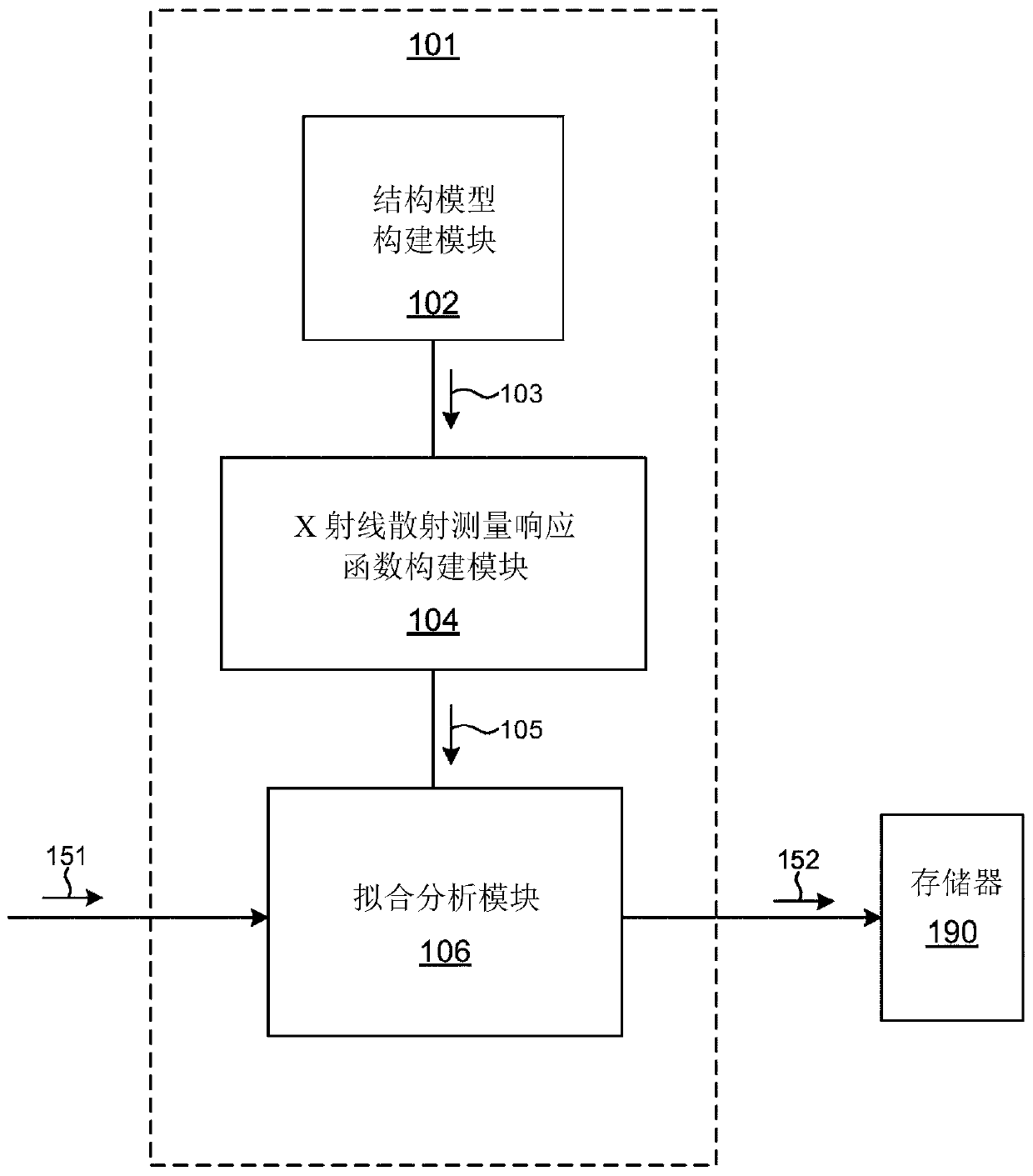

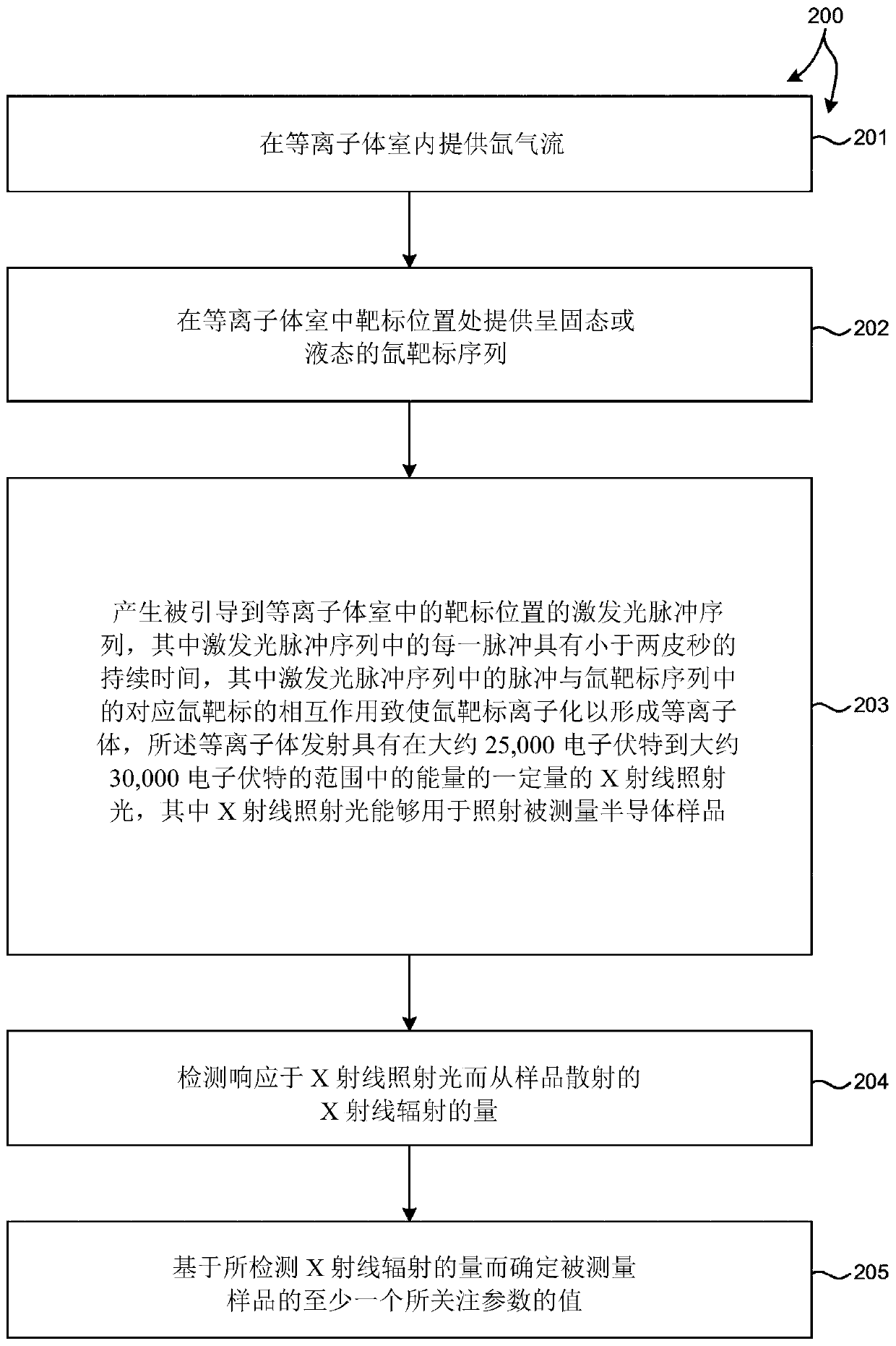

[0025] Methods and systems for x-ray-based semiconductor metrology utilizing clean, rigid x-ray radiation sources are described herein. More specifically, laser-produced plasma (LPP) light sources produce high brightness (that is, greater than 10 13 photon / (second.mm 2 .mrad 2), hard x-ray exposure. To achieve this high brightness, the LPP light source directs a highly focused (e.g., less than 10 micron illumination spot on the target), extremely short duration (e.g., less than 2 picoseconds) laser beam to a dense xenon target in liquid or solid state. The interaction of a focused laser pulse with a high-density xenon target induces a plasma. Radiation from the plasma is collected by collection optics and directed to the sample being measured. Due to the use of non-metallic target materials, the resultin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com