Maximise the value of a sulphide ore resource through sequential waste rejection

A technology of ore and ore flow, applied in the field of maximizing the value of sulfide ore resources through continuous waste discharge, can solve problems such as uneconomical, and achieve the effect of optimizing operating costs and optimizing mineral value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

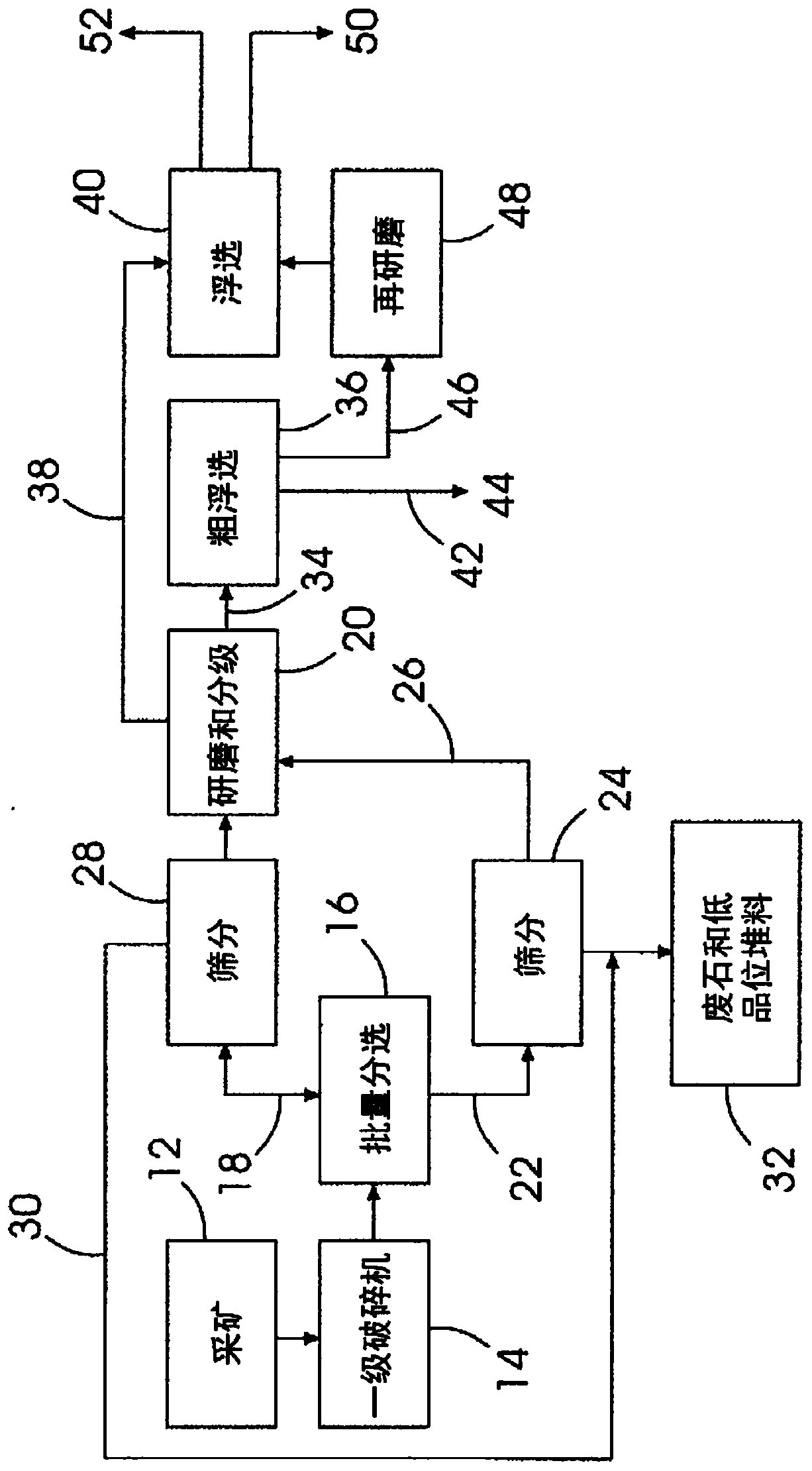

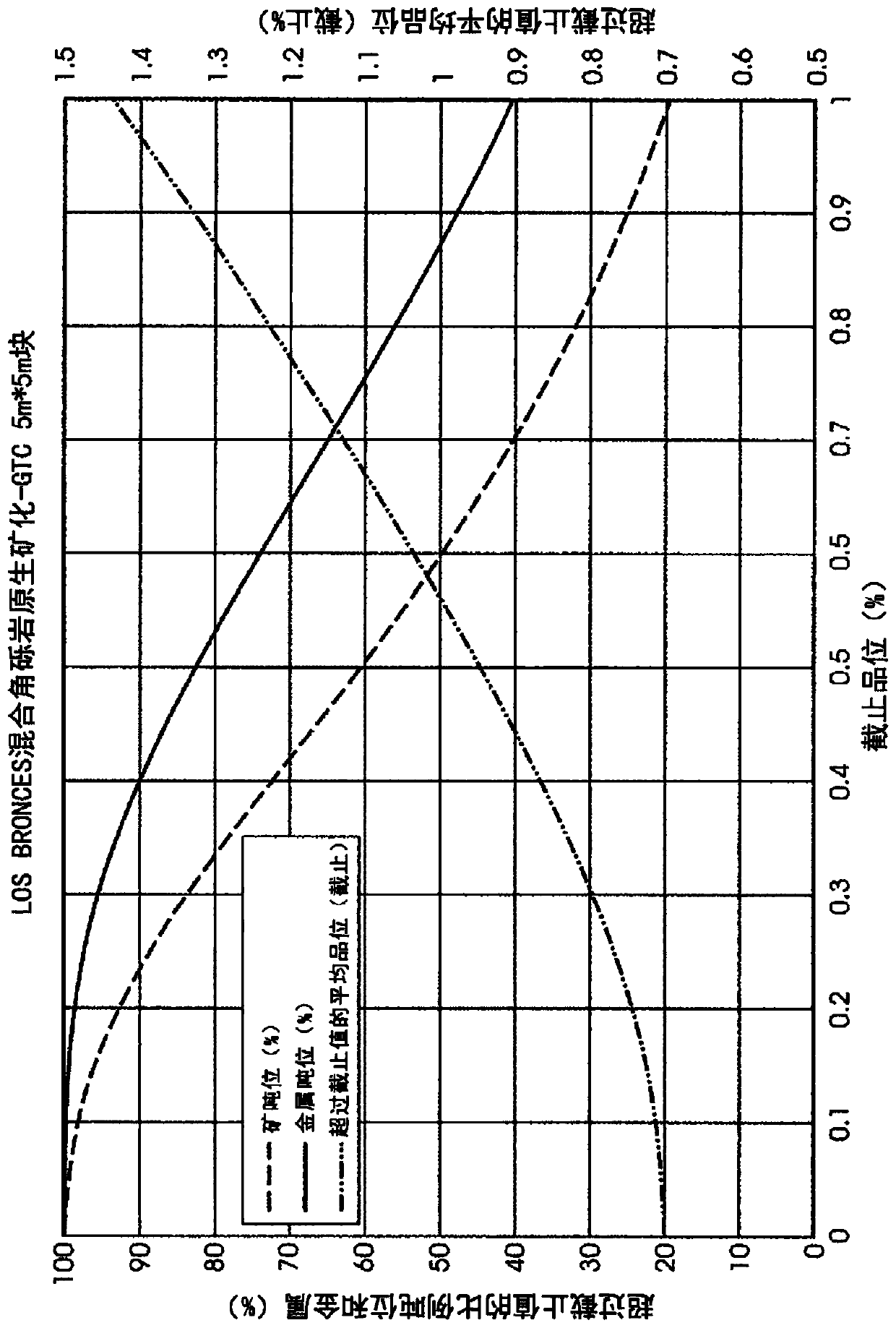

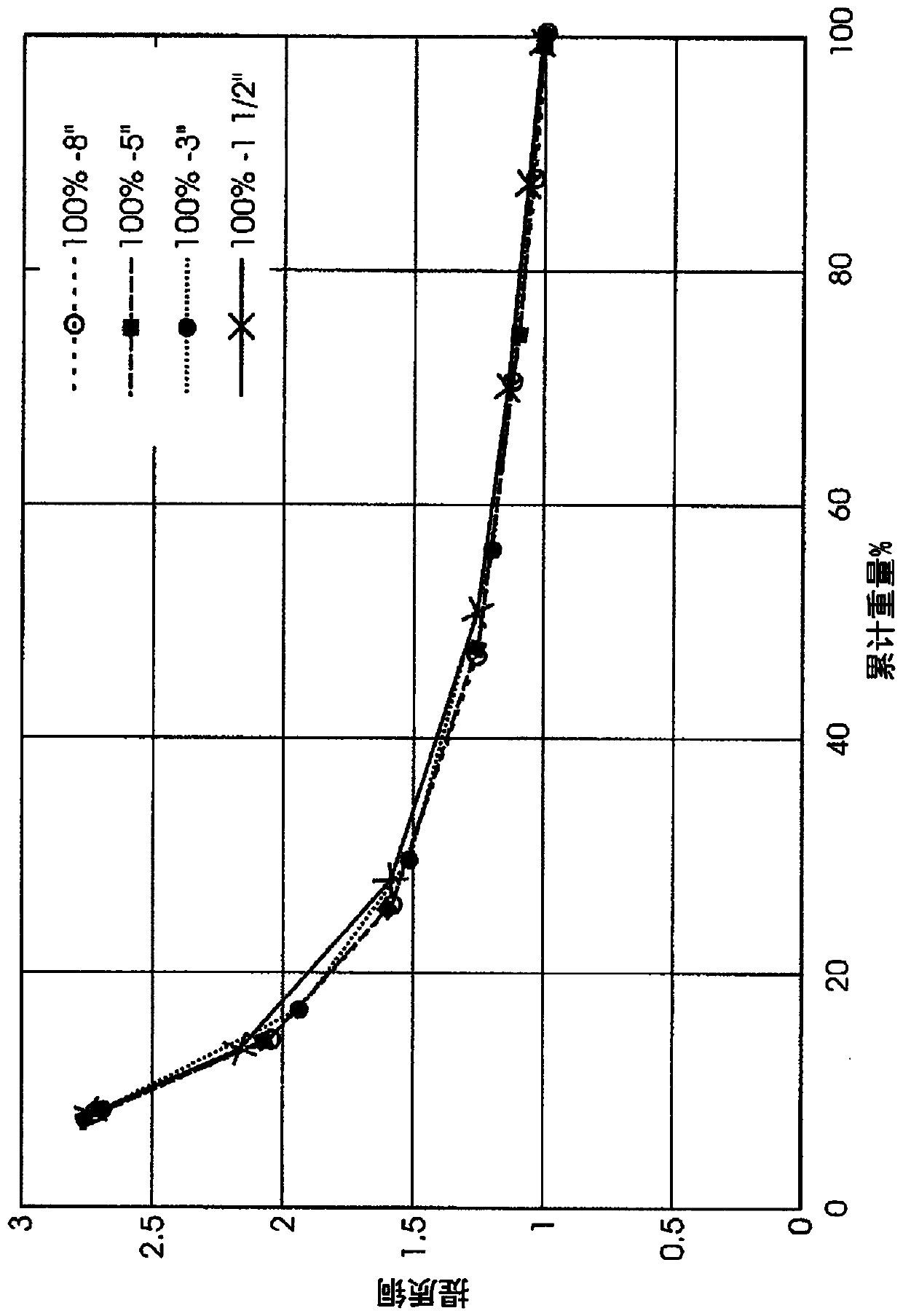

[0061] The present invention relates to a method that takes advantage of the natural heterogeneity of sulfide ore bodies and utilizes beneficiation techniques in a novel multistage configuration to remove the maximum amount of waste gangue prior to fine crushing. This excluded gangue is usually below economic reprocessing grade (ie waste), but can also be present as heap leaching feed; or as a low-grade stock that is processed later in the mine's life (grade analysis).

[0062] The exact amount of benefit will depend on the grade recovery characteristics of the particular ore body. However, using these technologies in combination, water and crushing energy consumption is typically reduced by 50-80% at the same mining cut-off grade (CoG). Alternatively, mining cut-off grades can be lowered, extending the life of the mine, achieving only slightly lower reductions in overall water and energy consumption. The present invention can also significantly reduce unit costs of productio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com