Mobile phone camera module surface inspection fixture

A camera module and surface detection technology, which is applied in image communication, television, branch office equipment, etc., can solve the problems of long time spent and achieve the effect of improving production efficiency and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

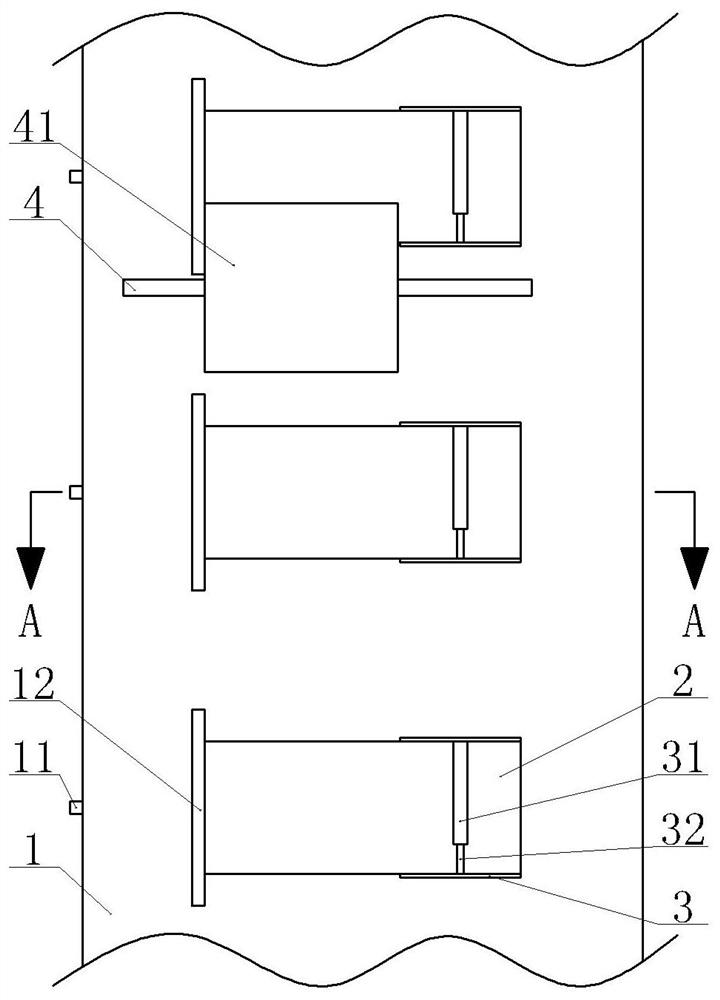

[0034] Mobile phone camera module surface inspection fixture, such as figure 1 As shown, it includes a frame, a driving part, a conveyor belt 1 and a pressing part. The frame is provided with two rotating shafts, both of which are arranged horizontally and both of which run through the frame and are matched with the frame. The two rotating shafts A driving wheel and a driven wheel are respectively arranged on the top, and the driving wheel, the driven wheel and the conveyor belt 1 constitute a conveyor belt mechanism. The driving member is fixed on the frame by bolts and connected with the rotating shaft where the driving wheel is located through a shaft coupling.

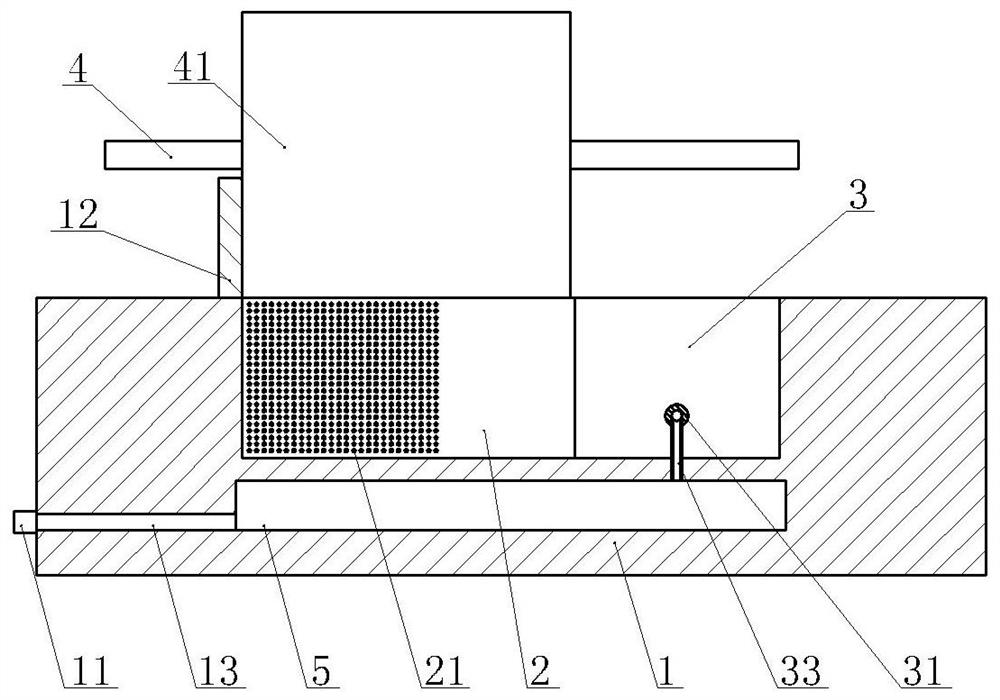

[0035] The conveyor belt 1 is provided with several detection units along the length direction of the conveyor belt 1, such as figure 2 As shown, the detection unit includes a detection groove 2 and an air intake pipe 13. The length of the detection groove 2 is greater than the sum of the lens of the camera and t...

Embodiment 2

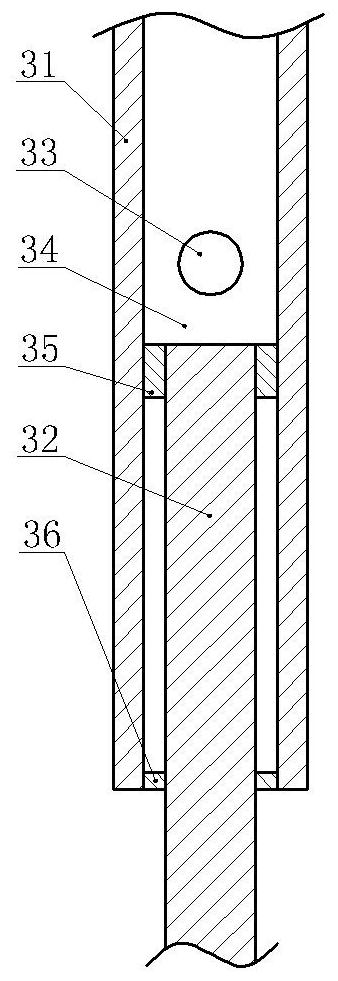

[0044] On the basis of Example 1, such as Figure 4 As shown, the conveyor belt 1 in this embodiment is vertically provided with a push-out chamber 6, the push-out chamber 6 is located below the lens accommodation area and below the pressurized chamber 5, the upper end of the push-out chamber 6 communicates with the pressurized chamber 5, and the push-out chamber A piston 61 is arranged transversely in the interior of the piston 6, and the piston 61 is slidingly sealed with the ejection chamber 6. The piston 61 separates the push-out chamber 6 into an upper slide-down chamber and a lower push-up chamber. A spring 65 is arranged in the push-up chamber, and the two ends of the spring 65 are welded to the bottom of the push-up chamber and the piston 61 respectively. A push rod 62 is glued vertically on the piston 61, and the upper end of the push rod 62 runs through the bottom of the conveyor belt 1 and extends into the detection tank 2; a ring-shaped positioning block 63 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com