Wavelet denoising method for partial discharge of DC gas-insulated electrical equipment

A technology for partial discharge and electrical equipment, applied in the field of partial discharge wavelet denoising of DC gas-insulated electrical equipment, can solve the problems of increasing signal standardization, re-sampling, complex calculation process, inapplicability, etc., to improve the risk factor evaluation and simple calculation , the effect of improving detection accuracy and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

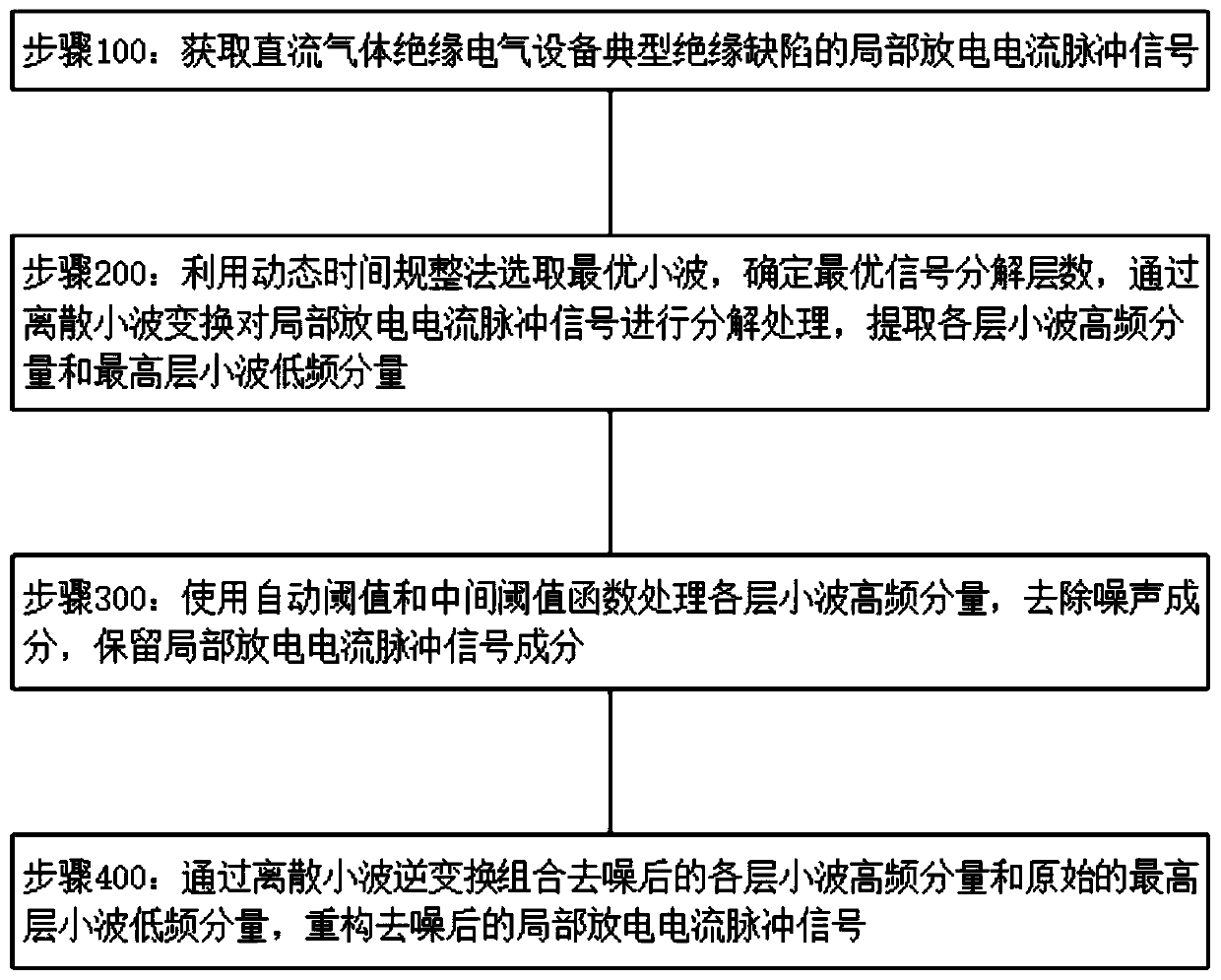

[0039] refer to Figure 1 to Figure 8 A partial discharge wavelet denoising method for DC gas-insulated electrical equipment is shown, which includes steps:

[0040] Step 1): Obtain partial discharge current pulse signals of typical insulation defects of DC gas-insulated electrical equipment;

[0041] Step 2): Using the dynamic time warping method to select the optimal wavelet, determine the optimal number of signal decomposition layers, decompose the partial discharge current pulse signal through discrete wavelet transform, and extract the wavelet high frequency components of each layer and the highest wavelet low frequency component;

[0042] Step 3): use automatic threshold and intermediate threshold functions to process wavelet high-frequency components of each layer, remove noise components, and retain partial discharge current pulse signal components;

[0043] Step 4): Combining the denoised wavelet high-frequency components of each layer and the original highest-level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com