Conductive plate, track lamp and production method of conductive plate

A technology of conductive plates and track lights, which is applied in the direction of electric light source, printed circuit parts, printed circuit secondary treatment, etc., can solve the problems of long production cycle and high cost of carbon oil, and achieve strong anti-color change ability, stable structure, good corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a two-wire single-loop conductive plate.

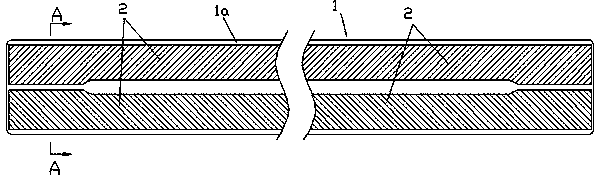

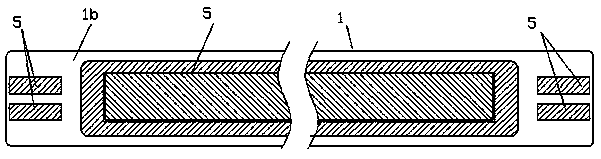

[0048] Such as Figure 1-5 As shown, a conductive plate 1 includes a substrate 10 and copper sheets 11 covering both sides of the substrate 10 , and the copper sheets 11 completely cover both surfaces of the substrate 10 .

[0049] The conductive plate 1 is an FR4 conductive plate, that is, the base material 10 of the conductive plate is a heat-resistant material, and FR4 is the code name of the flame-resistant material grade. The conductive plate 1 is a two-wire single-circuit conductive plate. The conductive plate 1 includes a conductive surface 1a and wiring On the surface 1b, two conductive strips 2 are arranged side by side on the conductive surface 1a, and a gap is left between the two conductive strips 2, so that the two conductive strips 2 are relatively independently arranged on the conductive surface 1a.

[0050] The two conductive strips 2 extend along the length direction of the conductive ...

Embodiment 2

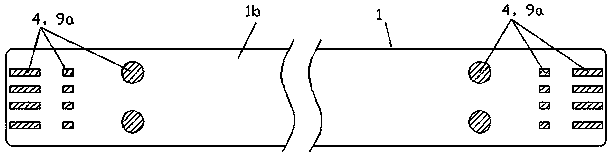

[0059] This embodiment provides a three-wire single-loop conductive plate.

[0060] The conductive plate in this embodiment is basically the same as that in Embodiment 1, except that this embodiment is a three-wire single-circuit conductive plate.

[0061] Such as Figure 6-8 As shown, the conductive plate 1 includes a conductive surface 1a and a wiring surface 1b, and three conductive strips 2 are arranged side by side on the conductive surface 1a, and a gap is left between two adjacent conductive strips 2, so that the three conductive strips 2 are relatively independently arranged on the conductive surface. By setting the through hole 6 and the inner wall of the through hole 6 is covered with a conductive layer, the three conductive strips 2 are respectively connected to the line 5 on the wiring surface to realize power conduction and / or signal transmission.

[0062] This embodiment is different from Embodiment 1 in that: the conductive plate 1 of this embodiment is provid...

Embodiment 3

[0065] This embodiment provides a track light.

[0066] Such as Figure 9 and 10 As shown, the track light includes a guide rail 8 and a conductive plate 1 fixed in the guide rail 8 as described in Embodiment 1 or Embodiment 2, and also includes a light source installed on the guide rail 8 (not shown in the figure), The light emitting source is electrically connected to the conductive plate 1 , so that the light emitting source passes through the conductive plate 1 and emits light.

[0067] The guide rail 8 of the track light has a certain length, so that the track light can slide in the guide rail 8 according to the usage conditions, thereby adjusting the irradiation position and the irradiation angle to meet different irradiation requirements. The length of the conductive plate 1 corresponds to the length of the guide rail 8, so that the When the light emitting source is slidably installed on the guide rail 8 , the light emitting source is always electrically connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com