Assembly method for embedded connection between ground beam and shear wall

An assembly method and shear wall technology, which can be applied to walls, protective buildings/shelters, and foundation structure engineering, can solve the problem of separation of two components, and achieve high bearing capacity, seismic performance, and good integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

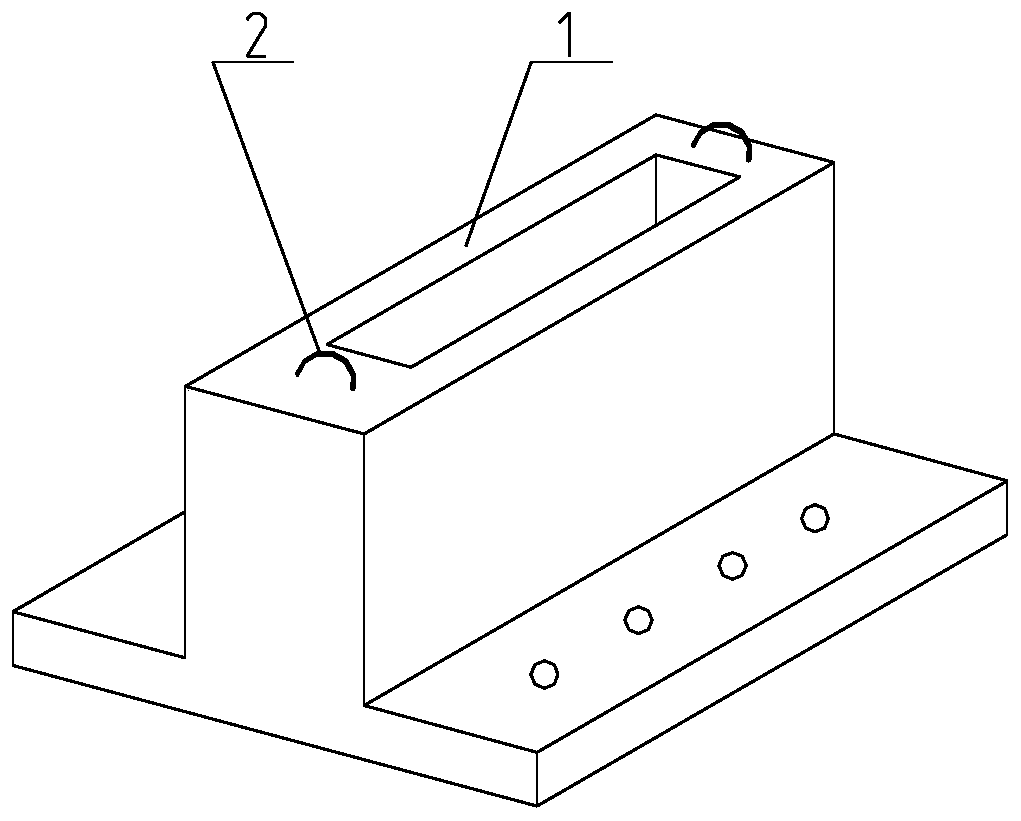

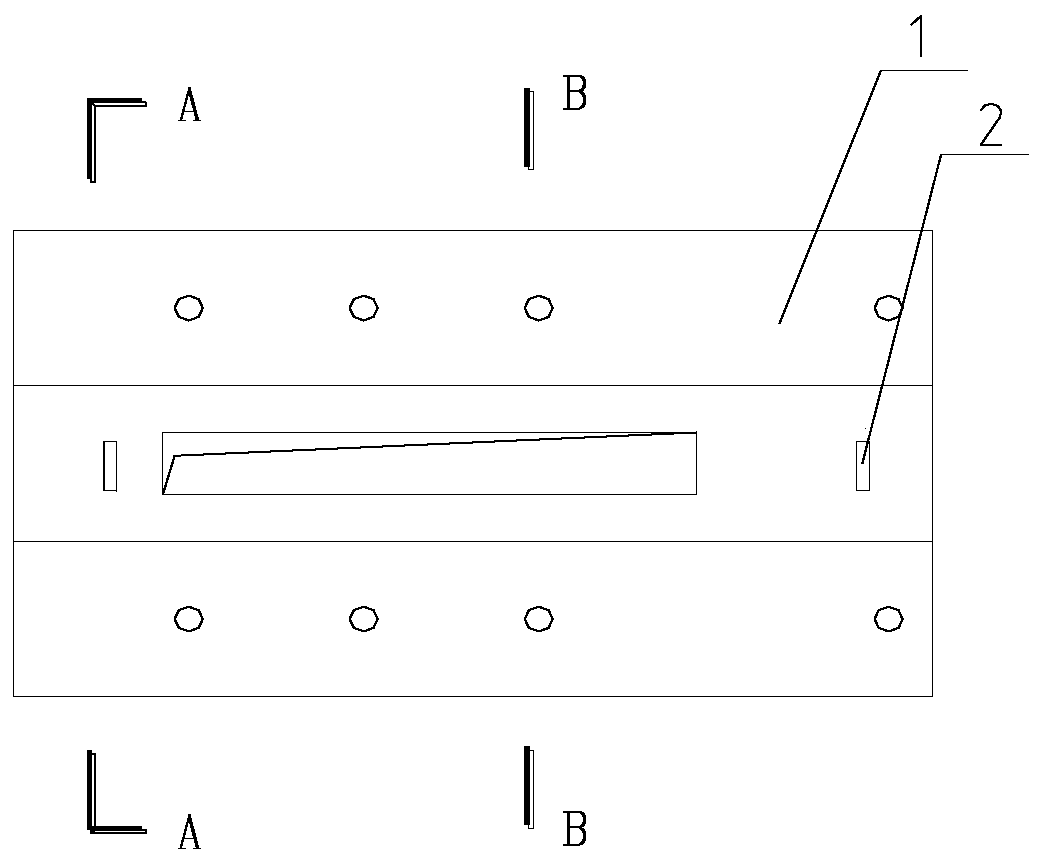

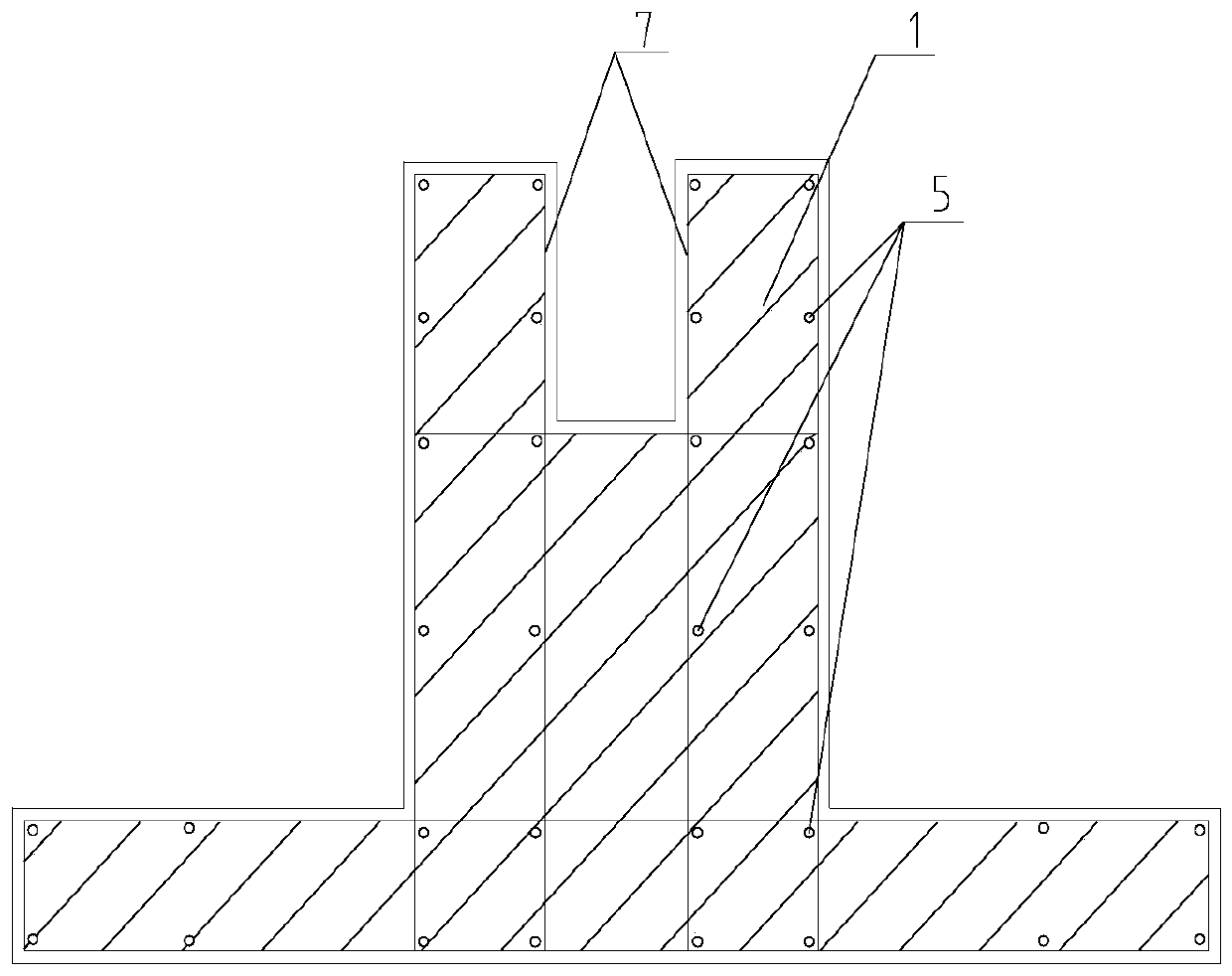

[0030] exist figure 1 , figure 2 , image 3 with Figure 4 The assembly method of the inlaid connection between the ground beam and the shear wall is shown in the ground beam schematic diagram, the middle part of the ground beam 1 is provided with a groove, and its length and width are respectively equal to the length and width of the shear wall plus the thickness of the concrete layer for connection. Specifically, the length is 1520mm, the width is 170mm, and the depth is 200mm. The depth of the groove corresponds to the height of the protruding part of the shear wall. In addition, a position other than the ground beam groove length direction is provided with a ground beam suspension ring 2 pre-embedded in the ground beam, and a reinforcing bar 5 and a reinforcement mesh sheet 7 are provided in the ground beam.

[0031] exist Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 The assembly method of the mosaic connection between the ground beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com