Dynamic filtering pressing dehydrator

A pressing dehydration and dynamic filtration technology, which is applied in filtration separation, dehydration/drying/concentrated sludge treatment, separation methods, etc., can solve problems such as long filtration time, increased specific resistance of filter cake, and complicated production of diaphragm filter plates, etc. Achieve good sealing effect and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

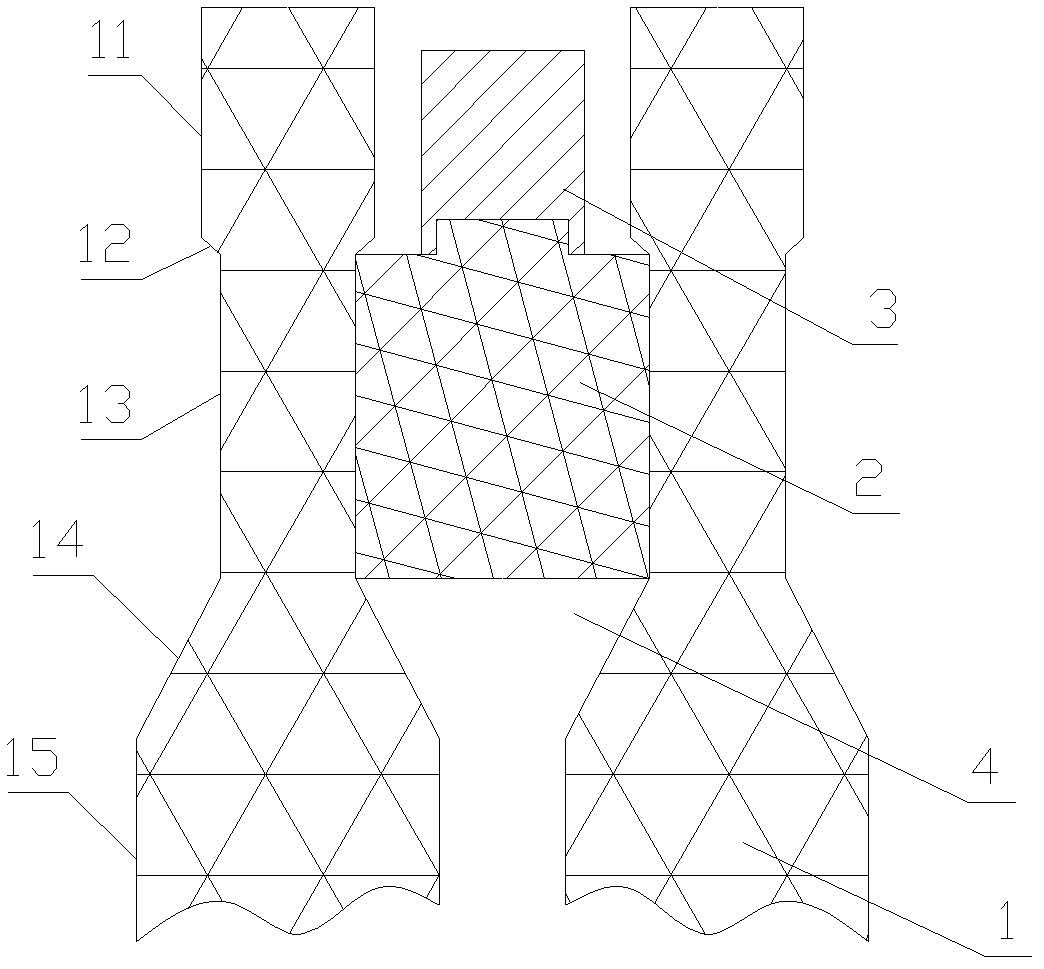

[0012] refer to figure 1 Illustrate the embodiment of the dynamic filter press dehydrator of the present invention, comprise at least one filter unit, each filter unit comprises two parallel filter plates 1, between the two filter plates, an elastic body 2 is arranged at the outer edge of the filter plate An elastic press frame composed of a filter frame 3, the filter frame 3 is arranged outside the elastic body, the thickness of the filter frame is smaller than the thickness of the elastic body, the elastic body and the filter plate are sealed and bonded, and the elastic press frame and two pieces The filter plate encloses the filter chamber 4, and the planes of the filter plates on both sides of the filter chamber are filter press planes. The thickness of the filter plate at 15 places on the press filter plane is greater than the thickness at 13 places on the elastic body bearing plane, and the thickness of the elastic body in the uncompressed state is greater than Elastomer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com