A construction method of armor joint based on angle steel

A construction method and technology of angle steel, applied in the direction of construction, building components, floors, etc., can solve the problems of high production cost, easy cracking of concrete, complex structure, etc., and achieve the effect of simple production, safe and reliable engineering quality, and good connection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

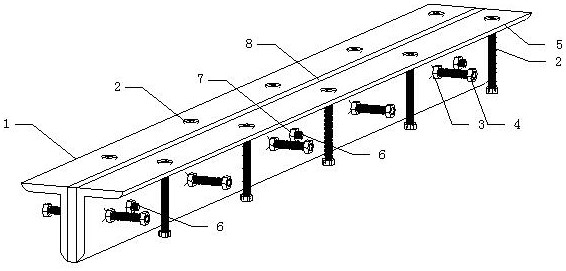

[0037] The armored seam construction method based on angle steel of the present invention, comprises the following steps:

[0038] a. Provide two angle steels, set a number of counterbore holes in the middle of the two outer right-angle side widths of the angle steels, and the distance between two adjacent counterbore holes is 200mm; the angle steels are equilateral or unequal angle steels. The specification of the angle steel is ∠75*75*8mm. The counterbore is arranged in a straight line on the right-angle side width of the angle steel. The countersunk bolts are M8 or M6 countersunk bolts.

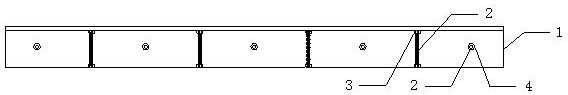

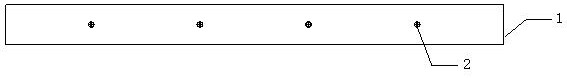

[0039] b. Provide several countersunk bolts, so that the screw of the countersunk bolt passes through the countersunk hole, and the head of the countersunk bolt sinks into the counterbore, and fits the wall of the countersunk hole; please refer to figure 1 with figure 2 , figure 1 It is a schematic diagram of the connecting structure of the countersunk bolt and the angle steel in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com