Novel construction process for preventing a constructional column from overflowing slurry

A construction technology and a technology for structural columns, which are applied in the field of new construction column anti-spill slurry construction technology, can solve the problems of concrete cement slurry overflow, large gap between formwork and bricks, and structural column hemp surface, etc., so as to avoid leakage and improve molding quality. , the effect of suppressing spillover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

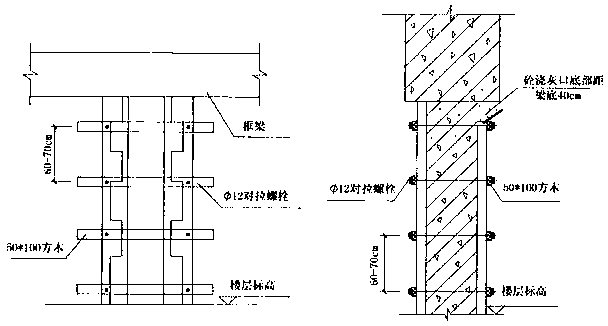

[0019] As shown in the figure, a new type of anti-overflow slurry construction technology for structural columns, the specific steps are:

[0020] Step 1: Leave the structural column in order to retreat first and then advance, and set up three retreats and three advances;

[0021] Step 2: Make the template according to the size of the construction column;

[0022] Step 3: Use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com