Embedded device for creeping formwork suspension

A pre-embedded device and climbing formwork technology, which is applied in the field preparation of formwork/formwork/working frame, building components, construction, etc., can solve problems such as poor load-bearing capacity, low construction efficiency, and affecting the aesthetics of the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

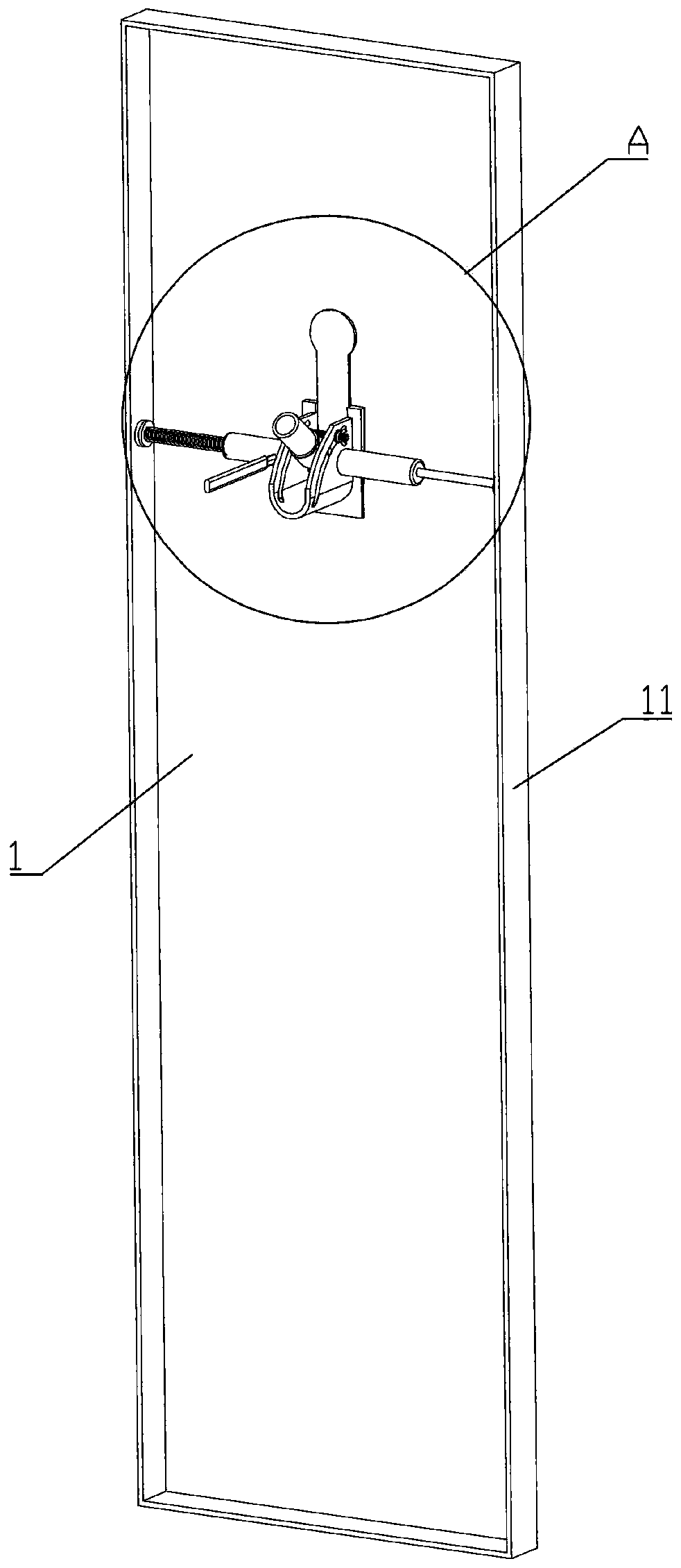

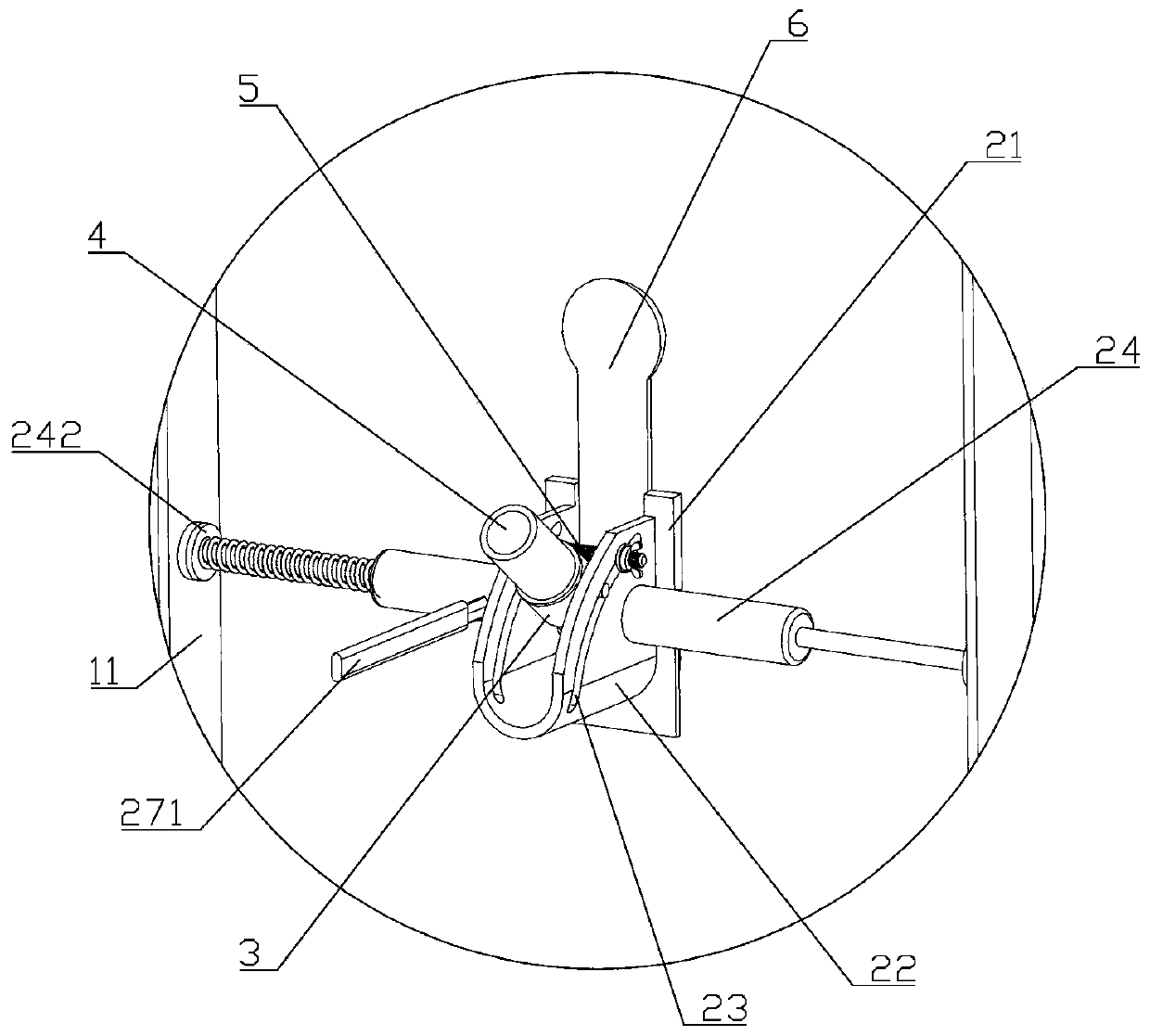

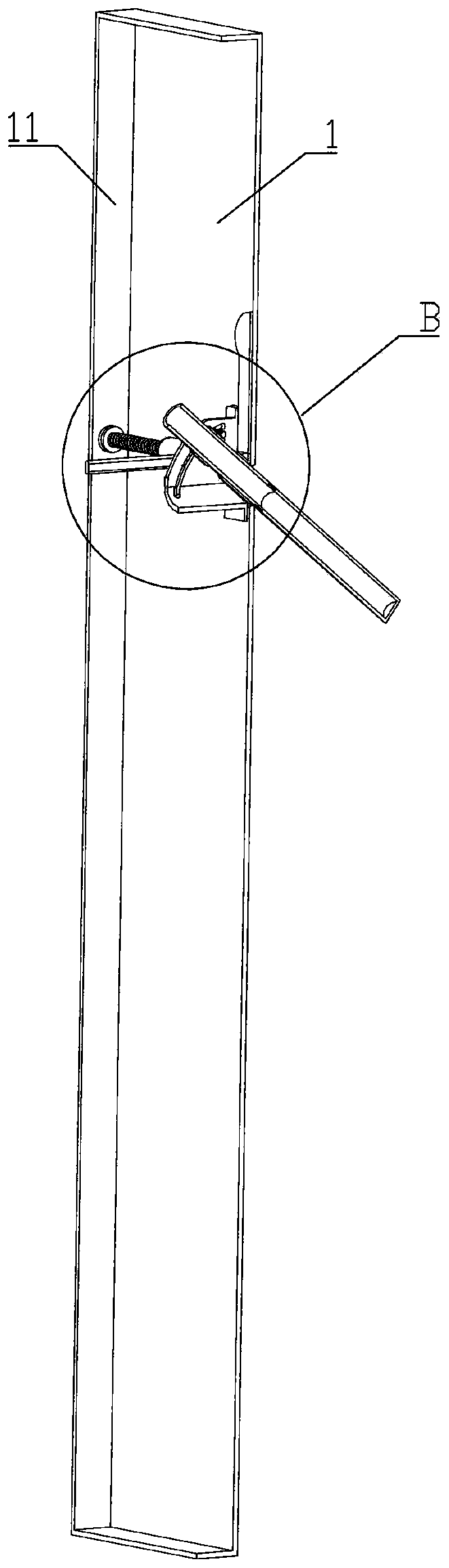

[0036] Such as Figure 1-10 As shown, a pre-embedded device for climbing formwork suspension, including a pre-embedded part 4 pierced on the aluminum formwork 1, the aluminum formwork 1 is provided with a back flute 11 and a reserved hole 12, and the pre-embedded part 4 is obliquely pierced Located in the reserved hole 12 of the aluminum template 1 , the embedded part 4 includes a fixed pipe 41 and an embedded pipe 42 . The embedded part 4 is connected with a fixing mechanism, and the fixing mechanism is fixedly installed on the aluminum formwork 1. The fixing pipe 41 is pierced on the fixing mechanism, and one end of the fixing pipe 41 is pierced in the reserved hole 12. The embedded pipe 42 and the fixing The pipe 41 is detachably connected, and after pouring and forming, the pre-embedded pipe 42 remains in the wall to form an inclined reserved hole. The fixing mechanism includes an integrally formed base 21 and a mounting frame 22, the side walls of the opposite sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com