High-color-fastness polyester microfiber dyeing method

A technology with high color fastness and dyeing method, applied in the direction of dyeing method, fiber type, fiber treatment, etc., can solve the problems of dye shedding, large specific surface area, poor dye fastness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

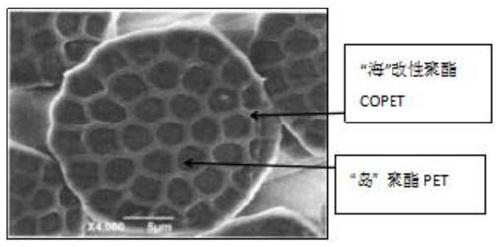

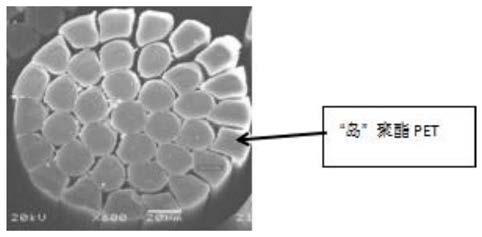

[0030] (1) Preparation of 37-island polyester Dingdao superfiber non-woven fabric: firstly, 37-island 5dtex×51mm, 70% PET / 30% COPET bicomponent Dingdao sea-island staple fiber is needle-punched to 400g / m 2 Polyester microfiber non-woven fabric.

[0031] (2) Water-based polyurethane impregnation: polyester microfiber non-woven fabric impregnated with a solid content of 35%, aliphatic water-based polyurethane with a viscosity of 600cps, polyester superfiber non-woven fabric impregnated with 220% liquid, and dried in an up and down blowing oven.

[0032] (3) Dyeing and finishing the non-woven fabric impregnated with polyurethane after drying: weigh the base fabric in step 2) and pour it into the dyeing vat, because the fiber fineness is 5dtex and the diameter is very small, the particle size of the disperse dye is selected Below 0.5 μm, because the particle size of the dye is small, the dispersibility in the solution is good. In the dyeing bath at 130 ° C, the disperse dye is eas...

Embodiment 1

[0035] 1) Preparation of 37-island polyester fixed-island superfiber non-woven fabric: the fineness is 5dtex, 70% PET / 30% COPET two-component 37-island fixed-island fiber is processed into a grammage of 400g / m through the acupuncture process 2 Microfiber non-woven fabric;

[0036] 2) Water-based polyurethane impregnation: impregnating water-washed polyurethane with a solid content of 35%;

[0037] 3) Dyeing and finishing the non-woven fabric impregnated with polyurethane and dried with disperse dyes: after drying at 220%, carry out high-temperature and high-pressure dyeing at 130°C, and select the particle size of disperse dyes to be about 2 μm;

[0038] 4) The base fabric in step 3) is subjected to alkali reduction treatment: after dyeing and washing, carry out alkali reduction finishing, the concentration of sodium hydroxide is 3%, react at 95°C for 60 minutes, and the polyester superfiber suede obtained after washing and drying leather.

[0039] The color fastness to wet ...

Embodiment 2

[0041] 1) Preparation of 37-island polyester fixed-island superfiber non-woven fabric: the fineness is 3.5dtex, 70% PET / 30% COPET two-component 37-island fixed-island fiber is processed into a grammage of 400g / m through the acupuncture process 2 Microfiber non-woven fabric;

[0042] 2) Water-based polyurethane impregnation: impregnating water-washed polyurethane with a solid content of 35%;

[0043] 3) Dyeing and finishing the non-woven fabric impregnated with polyurethane and dried with disperse dyes: after drying at 220%, carry out high-temperature and high-pressure dyeing at 130°C, and select the particle size of disperse dyes to be about 0.5 μm;

[0044] 4) The base fabric in step 3) is subjected to alkali reduction treatment: after dyeing and washing, carry out alkali reduction finishing, the concentration of sodium hydroxide is 3%, react at 95°C for 60 minutes, and the polyester superfiber suede obtained after washing and drying leather.

[0045] The color fastness to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com