Tire recycling and cutting device

A cutting device and tire technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of labor-intensive, labor-intensive, and low-efficiency tire skin cutting, and achieve a stable cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

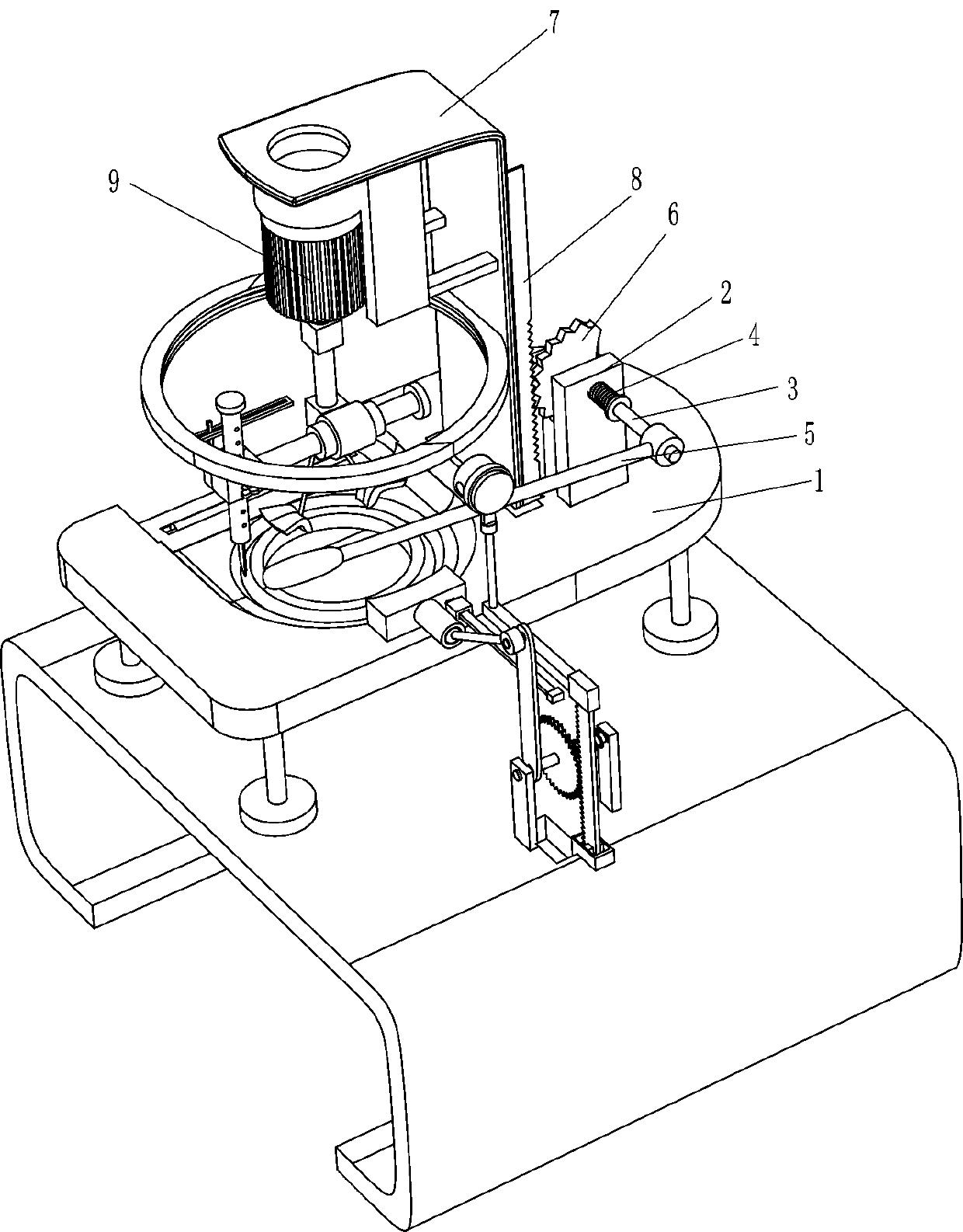

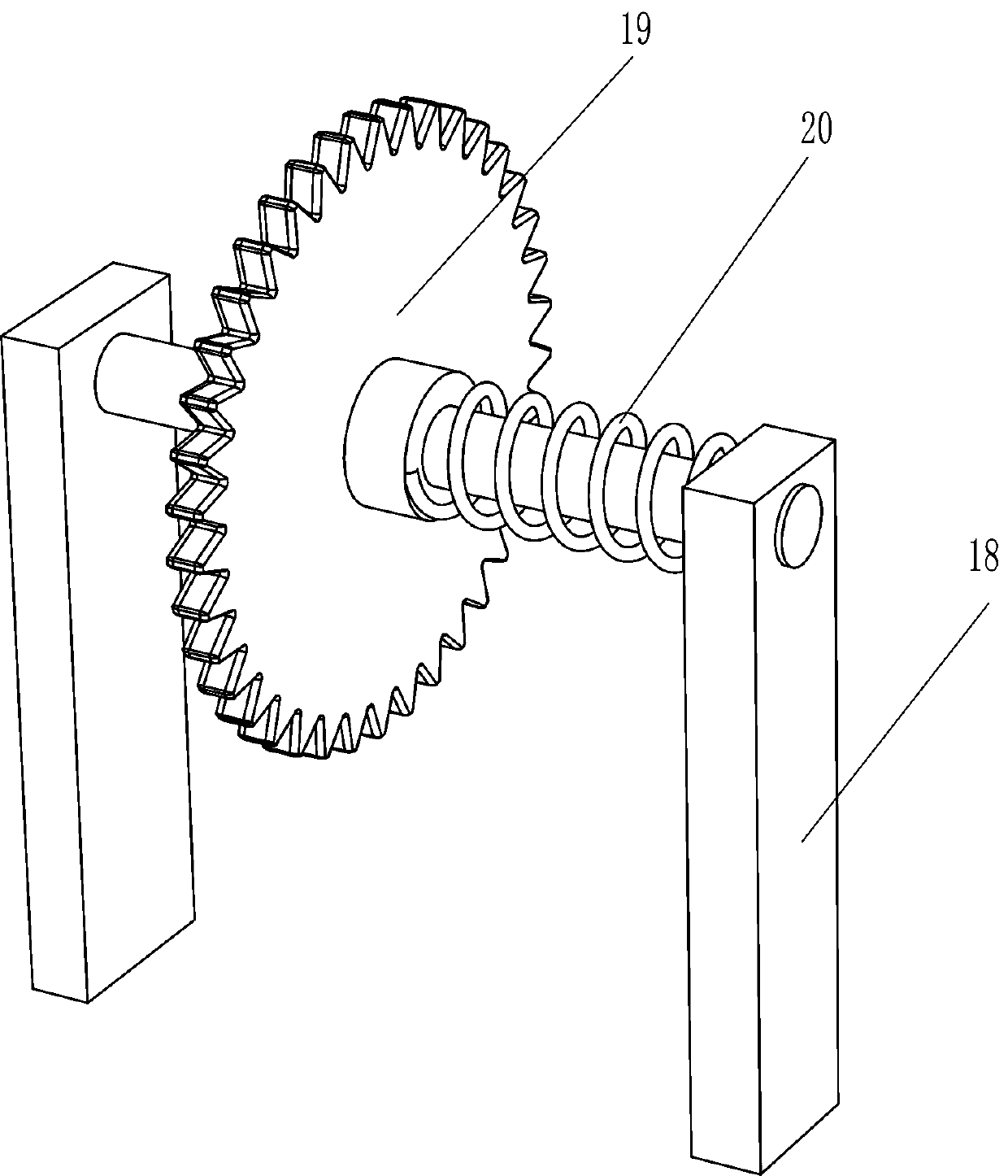

[0022] A tire recycling cutting device, such as Figure 1-3 As shown, it includes a support 1, a roller 201, a first support plate 2, a first rotating rod 3, a first return spring 4, a first swinging rod 5, a sector gear 6, a slide plate 7, a first rack 8, and a motor 9 and the cutting device 10, the upper left side of the workbench is provided with a support 1, the left part of the support 1 is embedded with a rotating drum 201, the upper side rear of the support 1 is provided with a slide plate 7, and the inside top of the slide plate 7 is installed There is a motor 9, the output shaft of the motor 9 is provided with a cutting device 10, the right part of the rear side of the slide plate 7 is provided with a first rack 8, and the support 1 on the rear side of the slide plate 7 is symmetrically provided with a first support plate 2. The upper part of the first support plate 2 on the left and right sides is rotatably provided with the first rotating rod 3, and the first rotati...

Embodiment 2

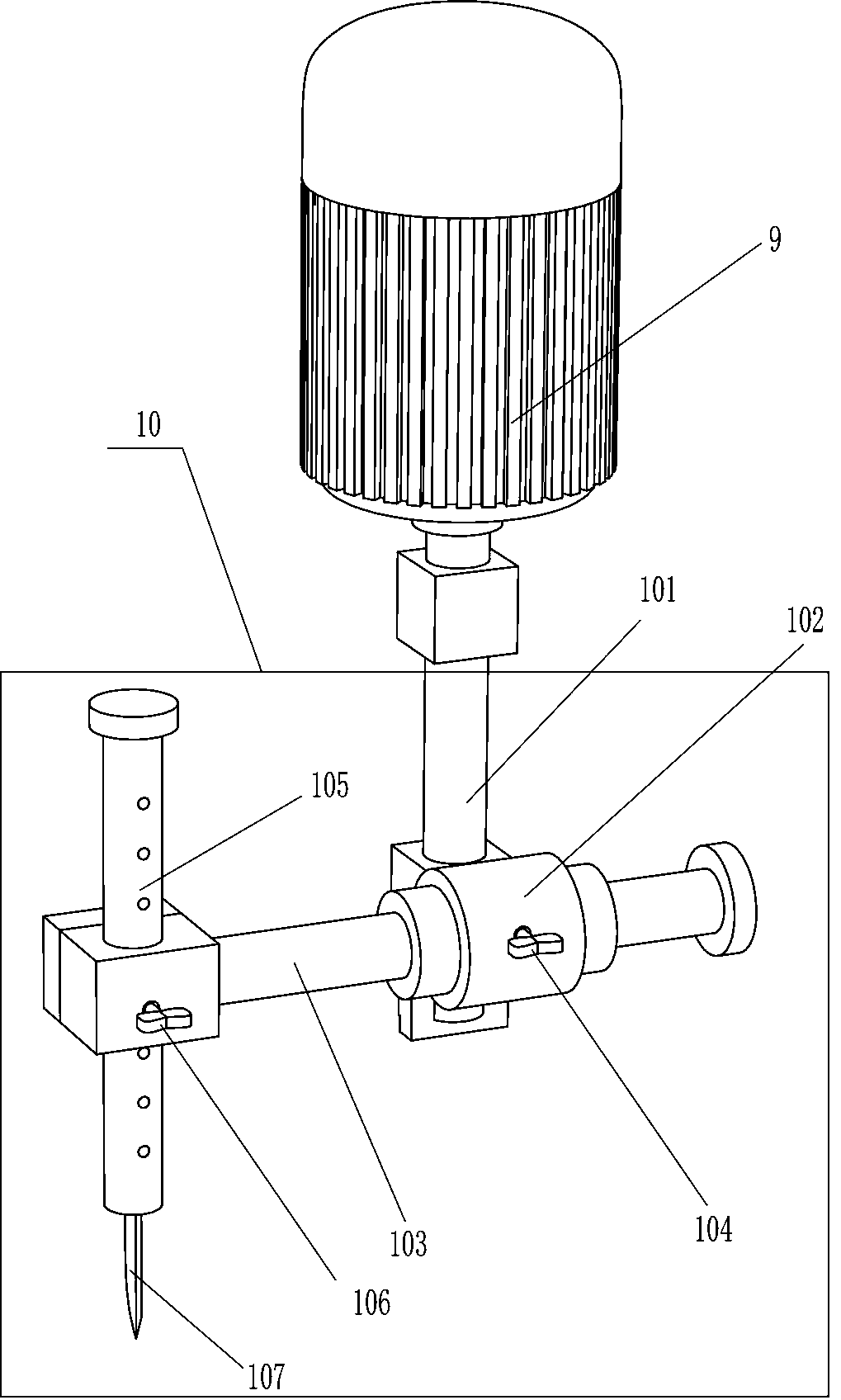

[0027] On the basis of Example 1, such as Figure 4-7 As shown, it also includes a fixed seat 11, a shaft sleeve 111, a second swing lever 12 and a second spring 13, the bottom end of the rotating shaft 101 is provided with a fixed seat 11, and the bottom of the fixed seat 11 is provided with a shaft sleeve 111, and the shaft sleeve 111 A second swing lever 12 is provided on the left side of the front and rear symmetrical rotation type, and a second spring 13 is arranged between the second swing lever 12 inner sides on the front and rear sides.

[0028]Also comprise annular slide rail 14, annular slide block 15, hollow slide bar 16 and pin bar 17, slide plate 7 inboard middle part is provided with annular slide rail 14, is provided with annular slide block 15 slidingly on annular slide rail 14, and annular slide block 15 is provided with a hollow slide bar 16, and the hollow slide bar 16 is slidably provided with a pin bar 17, and the bottom end of the pin bar 17 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com