Chain traction cutting trolley

A chain and trolley technology, which is applied in the field of chain traction and cutting trolleys, can solve problems such as affecting transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

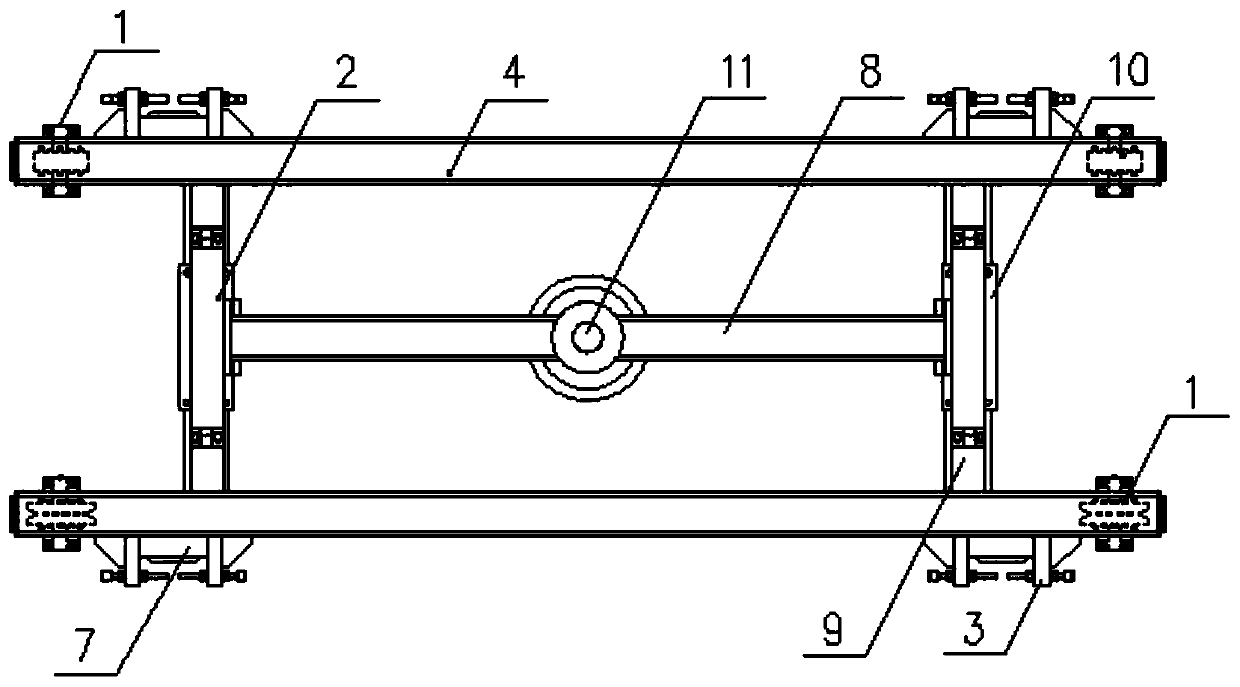

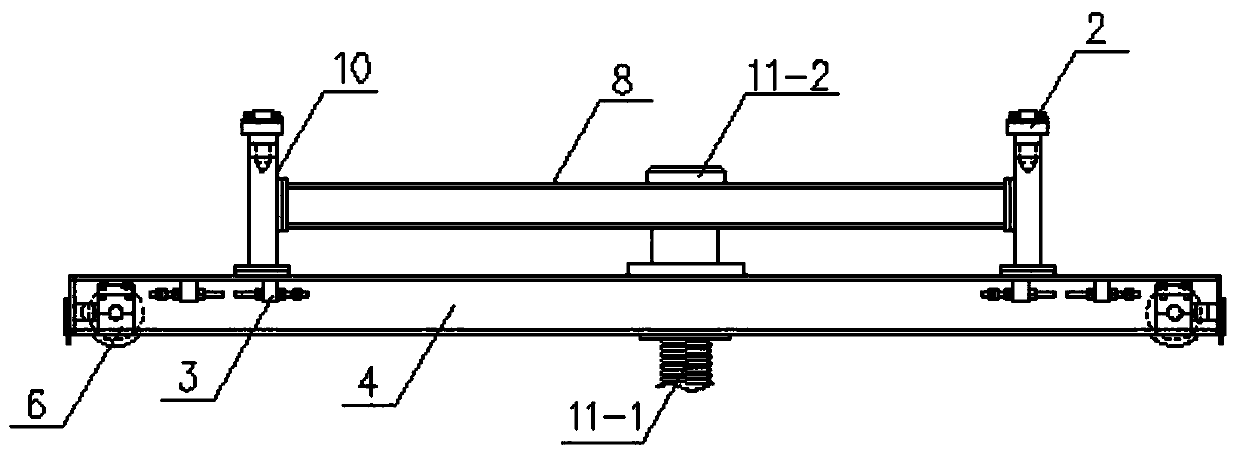

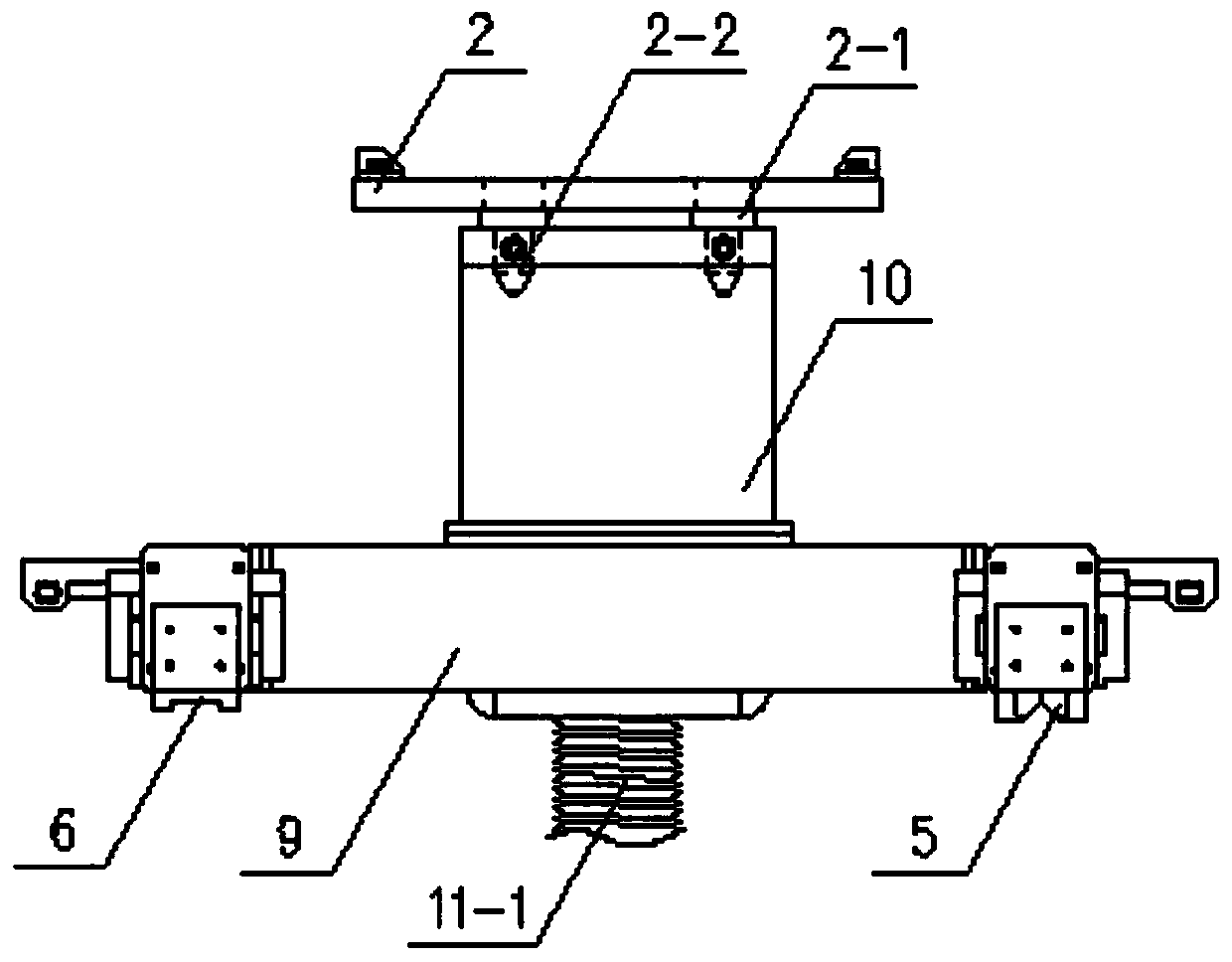

[0018] Such as figure 1 with figure 2 As shown, a chain traction cutting trolley includes a vehicle frame; a track obstacle removal device 1 is installed at the bottom of the vehicle frame 4, and a carrier 10 is vertically installed on the longitudinal beam 9 in the middle of the vehicle frame 4, and the carrier Bracket 2 is installed on 10, and four sets of chain joints 3 are installed on the side wall of vehicle frame 4. Bearing seat 7 is fixedly installed in the middle of said chain joint 3, and said bearing seat 7 is connected with sprocket through transmission shaft 3-2. 3-4, the sprocket 3-4 is engaged with the transmission chain for transmission. Among them, the driving motor drives the sprocket 3-4 to transmit the power to the chain joint 3, and the chain joint 3 drags the frame 4 to transport along the track. During the transportation, the trolley completes the real-time cleaning process for the track through the track clearing device 1 .

[0019] Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com