Cutting device for corrugated cardboard production line

A corrugated cardboard and cutting device technology, which is applied in metal processing and other directions, can solve problems such as collapse, foaming, degumming, and corrugation, and achieve the effects of stable cutting, stable cutting, and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

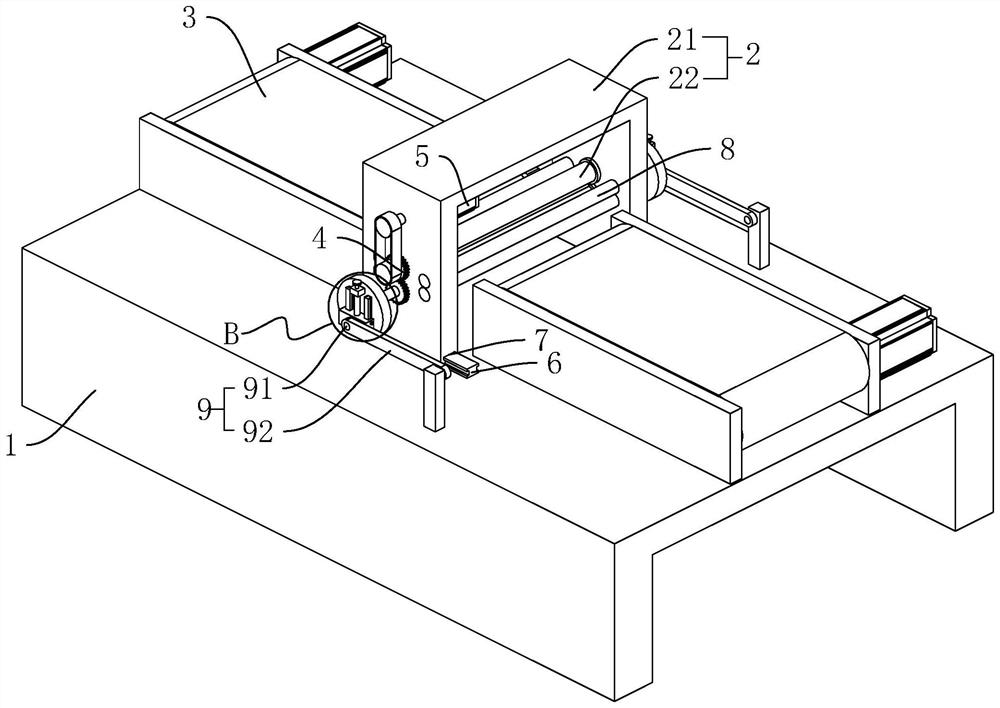

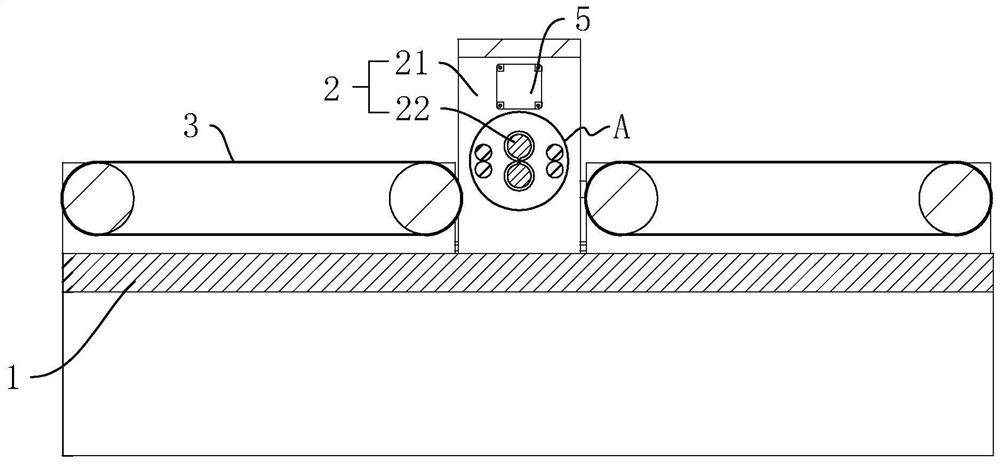

[0040] A cutting device for a corrugated cardboard production line, which is used to be installed between the slitting machine and the stacker of the corrugated cardboard production line, so that the corrugated cardboard coming out of the slitting machine is first cross-cut by the cutting device and then transported to the stacker for further processing. stack. likefigure 1 As shown, the cutting device includes a frame 1, the upper end of the frame 1 is provided with a cutting assembly 2, and the both sides of the cutting assembly 2 along the conveying direction of the corrugated cardboard are respectively provided with conveyor belts 3, and the corrugated cardboard can be further processed by the conveyor belt 3. delivery.

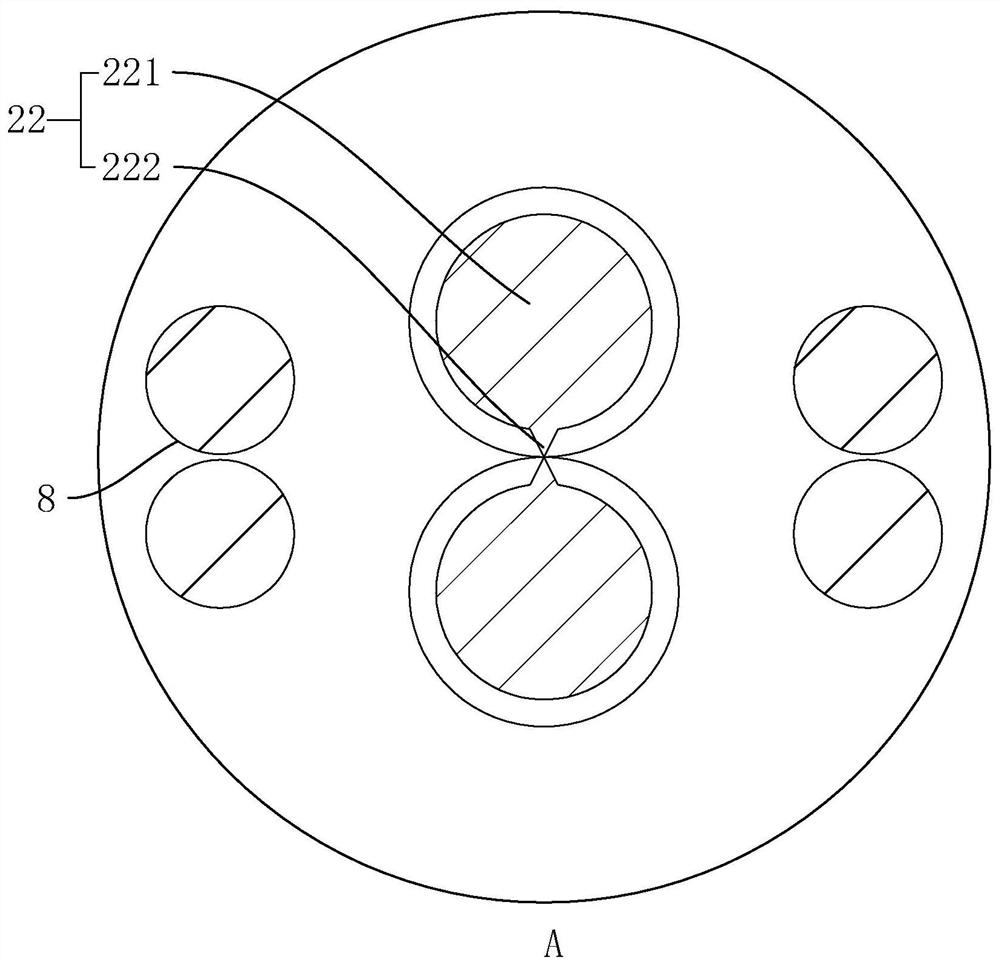

[0041] like figure 2 , image 3 As shown, the cutting assembly 2 includes a mounting frame 21 arranged on the frame 1, and two spiral knives 22 distributed up and down and rotatably connected to the mounting frame 21. The axes of rotation of the two h...

Embodiment 2

[0052] A cutting device for a corrugated cardboard production line, such as Figure 5 As shown, the difference from Embodiment 1 is that the structure of the transmission assembly 9 is different. Each transmission assembly 9 includes a mounting plate 93 fixedly arranged on the frame 1, two horizontal and opposite racks 94 arranged on the mounting plate 93, coaxially fixed on one of the rotating rollers 221 and connected to the two Rack 94 fits incomplete teeth 95 . The incomplete tooth 95 includes a rotating part 951 fixedly connected to the axial end of the rotating roller 221, and a plurality of tooth parts 952 fixed on the outer wall of the rotating part 951. Just after the upper rack 94 is disengaged, the tooth portion 952 is also just opened and engaged with the lower rack 94 . In actual use, the rotating part 951 of the incomplete tooth 95 is in the shape of a disc, and the diameter of the rotating part 951 can also be selected to be smaller, so that the reciprocating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com