Tilt frame adjustment mechanism

A technology of adjustment mechanism and tilting frame, which is applied in the field of plastic film production, can solve problems such as extrusion deformation of film bubbles and uneven thickness of film bubbles, achieve uniform thickness, convenient width adjustment, and improve film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

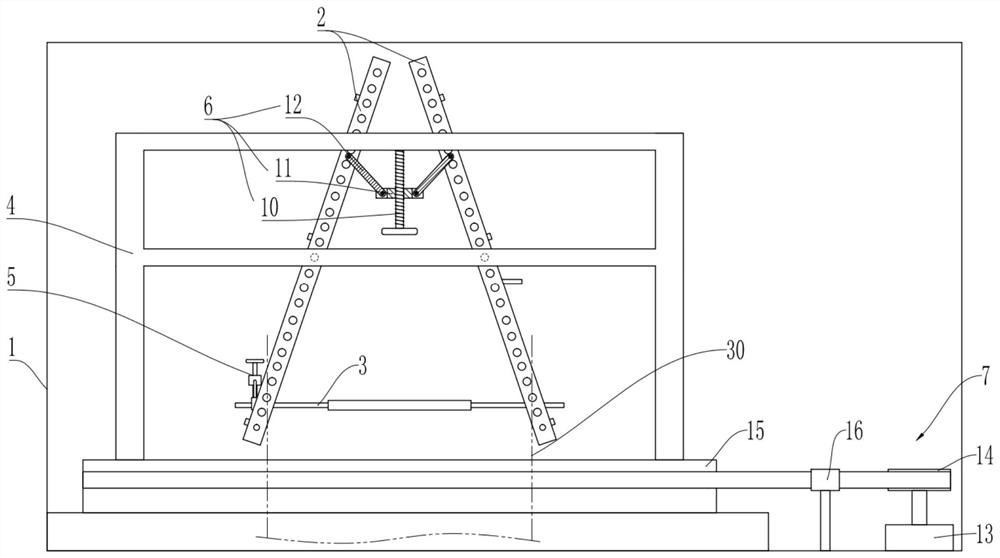

[0038] Embodiment one is basically as attached Figure 1 to Figure 3 Shown:

[0039] The tilting frame adjustment mechanism includes a frame 1, a herringbone plate, a limit roller 3, a support frame 4, a width adjustment assembly 5, an angle adjustment assembly 6 and a drive assembly 7 located on the frame 1. The herringbone plate includes two opposite The tilting frame 2, the limit roller 3 is located between the two tilting frames 2; the two tilting frames 2 and the supporting frame 4 are connected and rotated to be connected with a rotating shaft, the inclined frame 2 is suspended on the supporting frame 4 through the rotating shaft, and the drive assembly 7 Used to drive the support frame 4 to rotate.

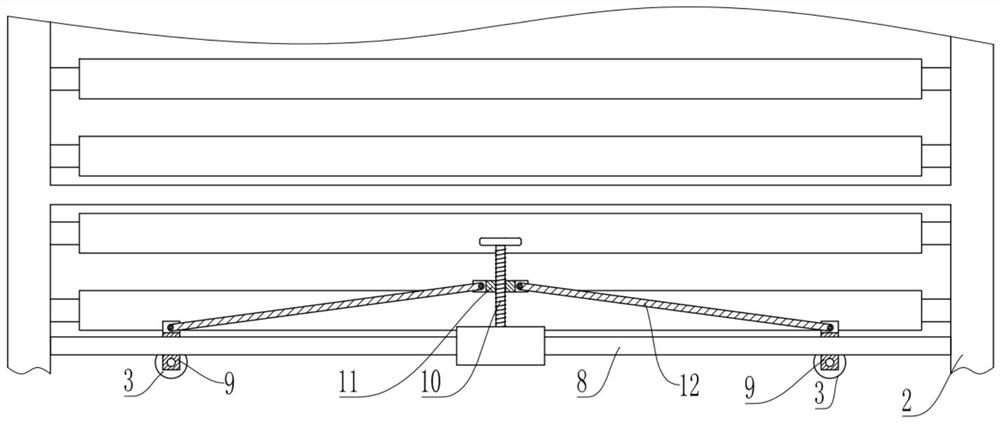

[0040] combine figure 2 , the two inclined frames 2 are provided with a horizontal slide bar 8, the slide bar 8 is provided with a slide block 9, and the slide block 9 slides laterally on the slide bar 8 through a bearing.

[0041] The left end of limit roller 3 is slid...

Embodiment 2

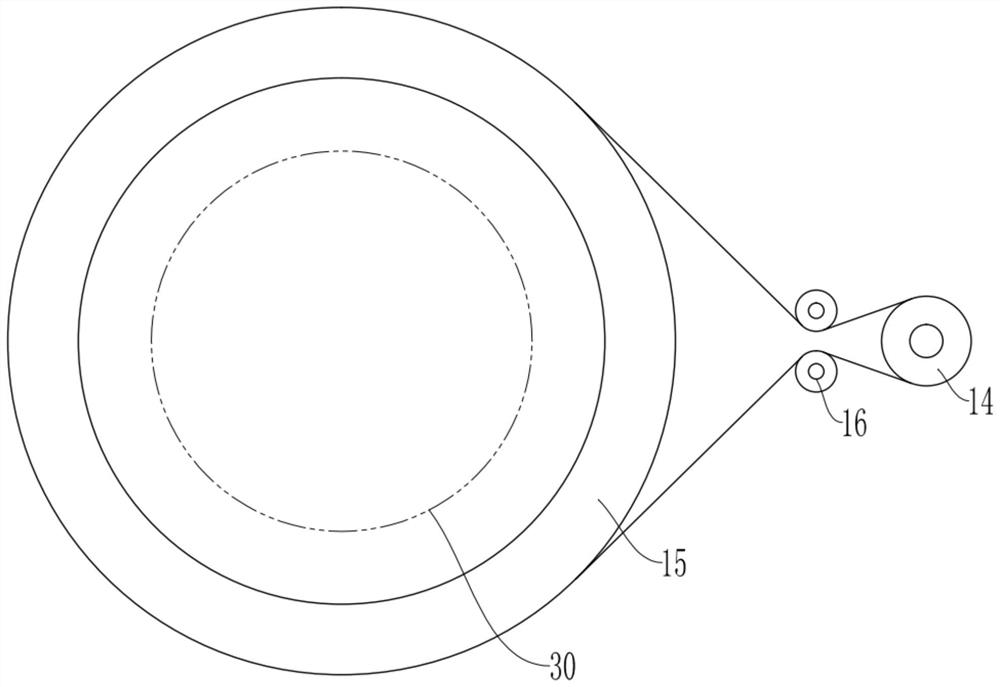

[0051] Embodiment two is basically as attached Figure 4 to Figure 6 Shown:

[0052] In Embodiment 2, a humidification assembly 17 is added on the basis of Embodiment 1. The humidification assembly 17 includes a rotating plate 18 and several humidification tubes 19 uniformly distributed along the circumference of the film bubble 30. Several humidification tubes 19 enclose the film bubble 30. The frame 1 A cover plate 20 is installed on the cover plate 20 through screws, the humidifying cylinder 19 is fixed on the cover plate 20 through screws, and the rotating plate 18 is connected with the turntable 15 through bolts.

[0053] to combine Figure 4 and Figure 5 The humidifying cylinder 19 is provided with a connecting rod 21 and a piston 22, the piston 22 is vertically slidably connected in the humidifying cylinder 19, the bottom end of the connecting rod 21 is fixedly connected with the piston 22, the top of the connecting rod 21 passes through the humidifying cylinder 19, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com