Column type hollow fiber filter membrane and preparation method thereof

A fiber filter membrane and split-type technology, which is applied in the field of split-type hollow fiber filter membranes and its preparation, can solve the problems of easy water leakage at the joints of the membrane shell, low overall strength of the membrane shell, and difficulty in leak point detection, etc., to achieve the packaging method Simplicity, high packaging efficiency, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

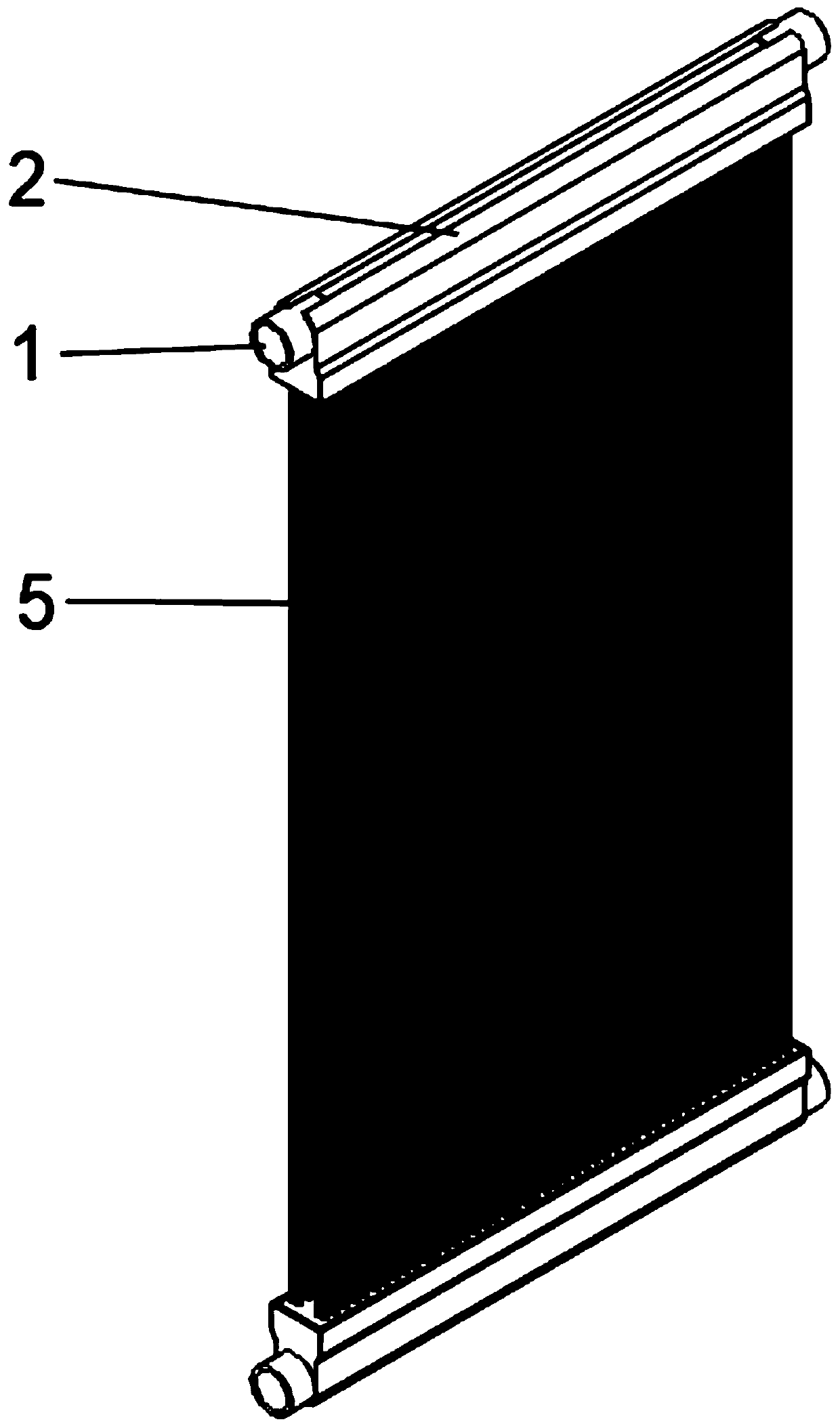

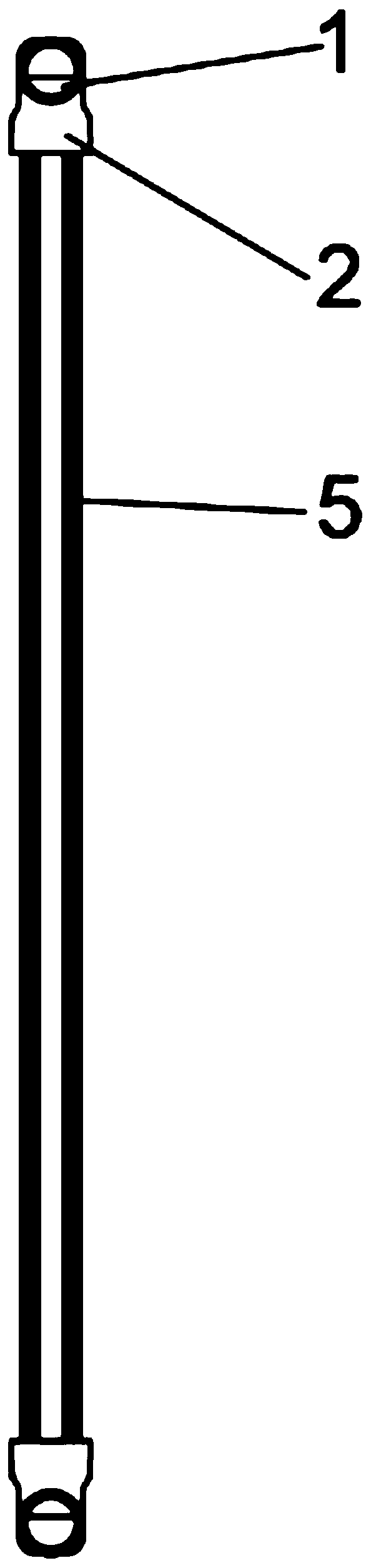

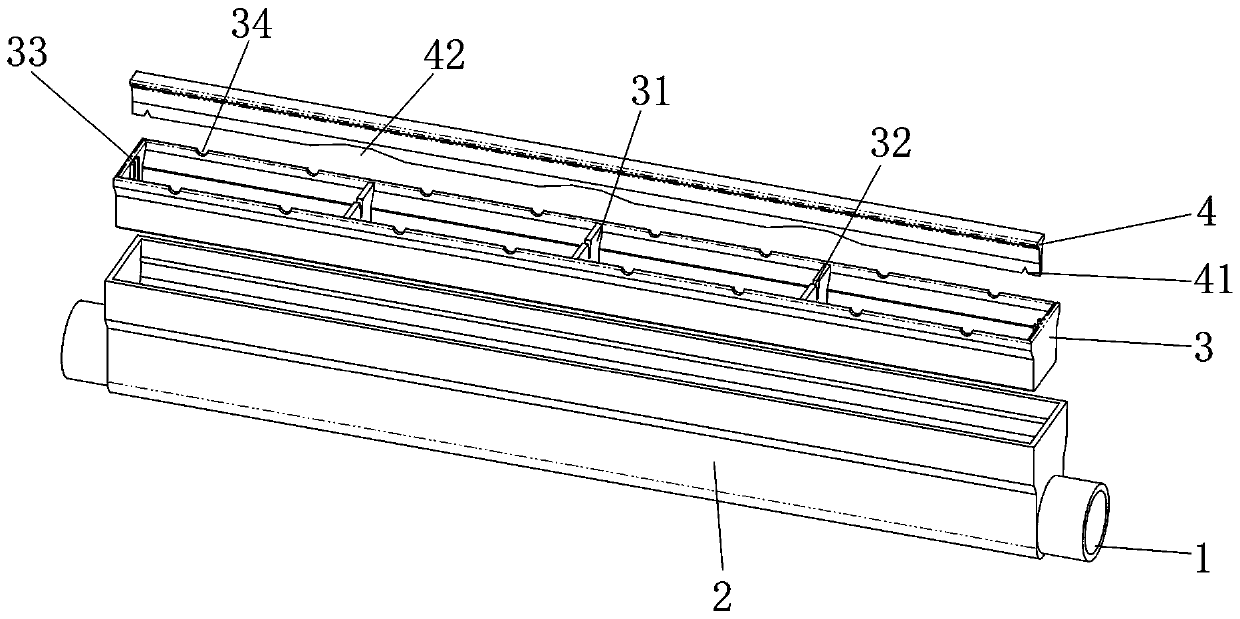

[0060] Such as Figure 1~Figure 4 Shown is a split-type hollow fiber filter membrane, which is prepared according to the following steps:

[0061] (1) Insert the membrane filament with the blocked end into the membrane filament packaging groove (3), and divide the membrane filament (5) into left and right rows with the membrane filament parting strip (4), and place the membrane filament parting strip (4) ) into the matching positioning groove (32) in the film packaging groove (3), and fill the film packaging glue (8);

[0062] (2) After the membrane filament packaging glue (8) is solidified, cut off the bottom of the membrane filament packaging groove (3), and cut out the membrane filament end hole (10);

[0063] (3) Bond the membrane filament packaging groove (3) to the water collecting pipe (2) with the membrane shell adhesive glue (6);

[0064] (4) Fill the membrane filament packaging glue (8) in the water collection pipe (2), and the membrane filament packaging glue (8) ...

Embodiment 2

[0088] A split type hollow fiber filter membrane is prepared according to the following steps:

[0089] (1) Insert the membrane filament with the blocked end into the membrane filament packaging groove, and divide the membrane filament into two rows on the left and right with the membrane filament parting strip, insert the membrane filament parting strip into the matching bayonet in the membrane filament packaging groove In the middle, filling film packaging glue;

[0090] (2) After the membrane filament packaging glue is solidified, cut off the bottom of the membrane filament packaging groove, and cut out the membrane end hole;

[0091] (3) Bond the membrane filament packaging groove to the water collecting pipe with the membrane shell bonding glue;

[0092] (4) Filling the water collection pipe with the membrane filament packaging glue, the membrane filament packaging glue completely submerges the membrane filament packaging groove and the membrane filament parting strip, a...

Embodiment 3

[0102] Such as figure 1 , figure 2 , image 3 with Figure 5 Shown is a split-type hollow fiber filter membrane, which is prepared according to the following steps:

[0103] (1) Insert the membrane filament with the blocked end into the membrane filament packaging groove, and divide the membrane filament into two rows on the left and right with the membrane filament parting strip, insert the membrane filament parting strip into the matching bayonet in the membrane filament packaging groove In the middle, filling film packaging glue;

[0104] (2) After the membrane filament packaging glue is solidified, cut off the bottom of the membrane filament packaging groove, and cut out the membrane end hole;

[0105] (3) Bond the membrane filament packaging groove to the water collecting pipe with the membrane shell bonding glue;

[0106] (4) Filling the water collection pipe with the membrane filament packaging glue, the membrane filament packaging glue completely submerges the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com