Device and method for regulating tar and ammonia water separation effect

A technology of tar ammonia water separation and tar, which is applied in the direction of liquid separation auxiliary equipment, etc., can solve problems such as difficult to ensure the separation effect of tar ammonia water, affect tar deep processing production, and unfavorable gas purification production, so as to improve tar deep processing production operation and significant economic benefits and safety benefit, stable coke oven and gas purification production operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

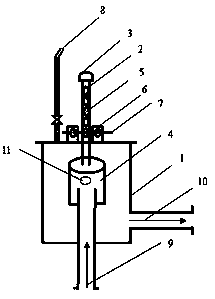

[0022] Below in conjunction with the accompanying drawings, the present invention will be further described by examples.

[0023] Refer to the attached figure 1 , a device for regulating the separation effect of tar and ammonia water, comprising a tank body 1, an adjusting rod 2, a handle 3, a movable sleeve 4, a positioning hole 5, a positioning seat 6, a positioning pin 7, a releasing cylinder 8, a tar inlet pipe 9, a tar The outlet pipe 10 and the overflow hole 11, the movable sleeve 4 is located in the tank body 1, and the movable sleeve 4 is provided with an overflow hole 11; It is directly fixed on the positioning seat 6, the lower end of the adjusting rod 2 is fixedly connected with the movable sleeve 4, the upper end of the adjusting rod 2 is provided with a handle 3, and the adjusting rod 2 is provided with a plurality of positioning holes 5 matched with the positioning pins 7; The bottom of the tank body 1 is connected to the tar inlet pipe 9, the tar inlet pipe 9 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com