Low bend loss optical fiber with a chlorine doped core and offset trench

A core, fiber technology, applied in the direction of multi-layer core/clad fiber, graded index core/clad fiber, clad fiber, etc., can solve the problem of low microbending loss, difficult macrobending loss, low Cable cut-off wavelength and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach A

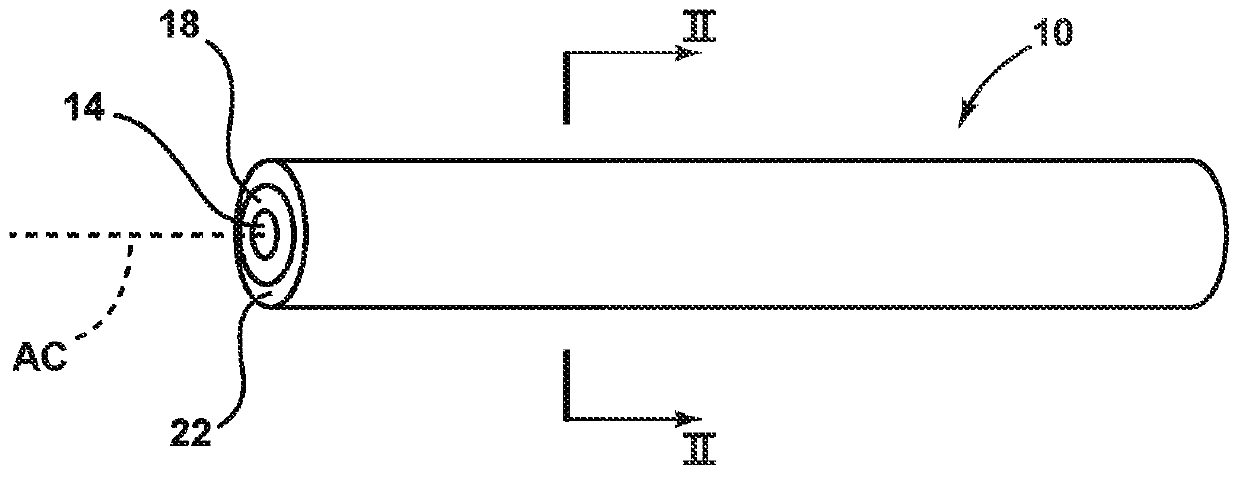

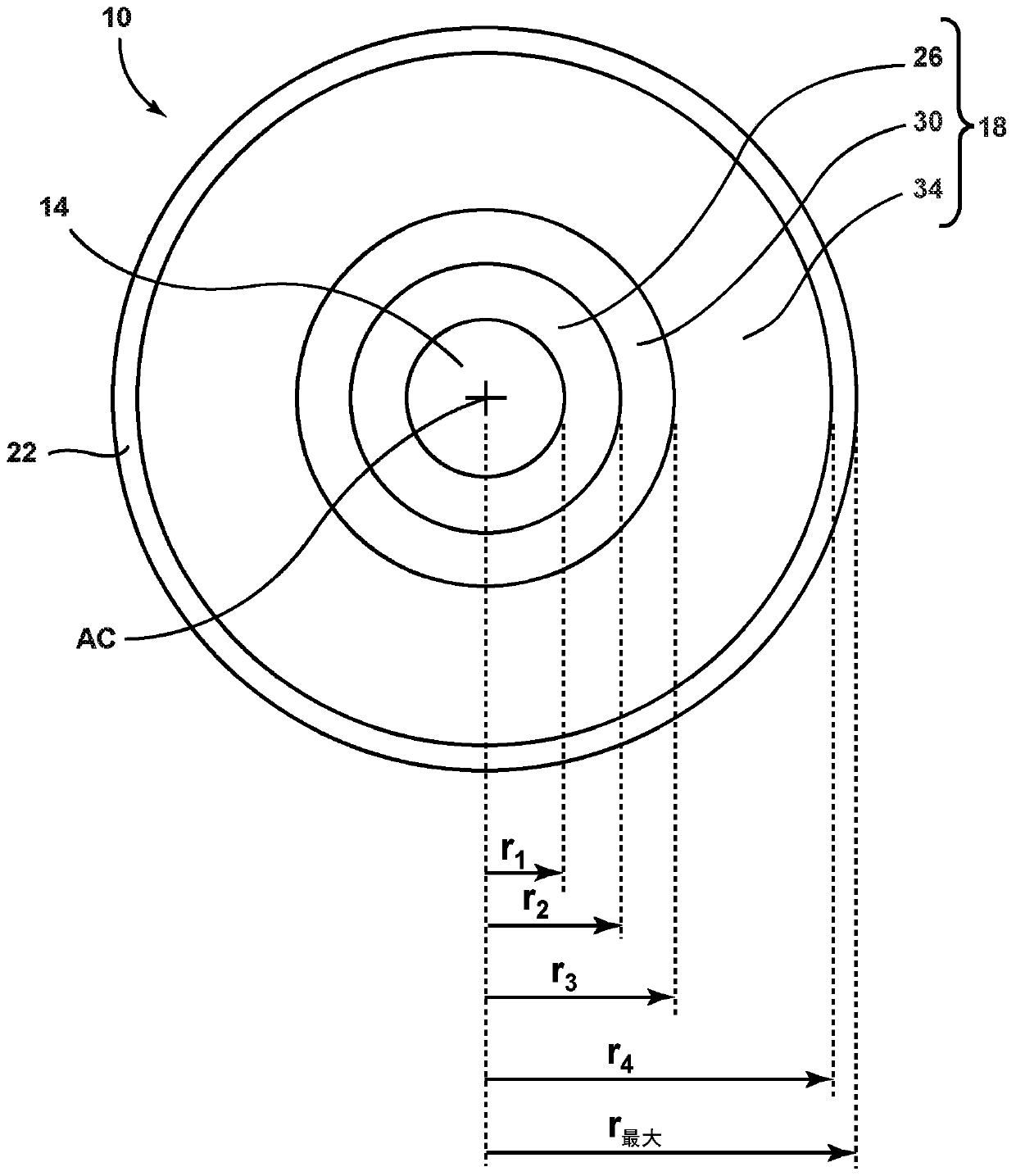

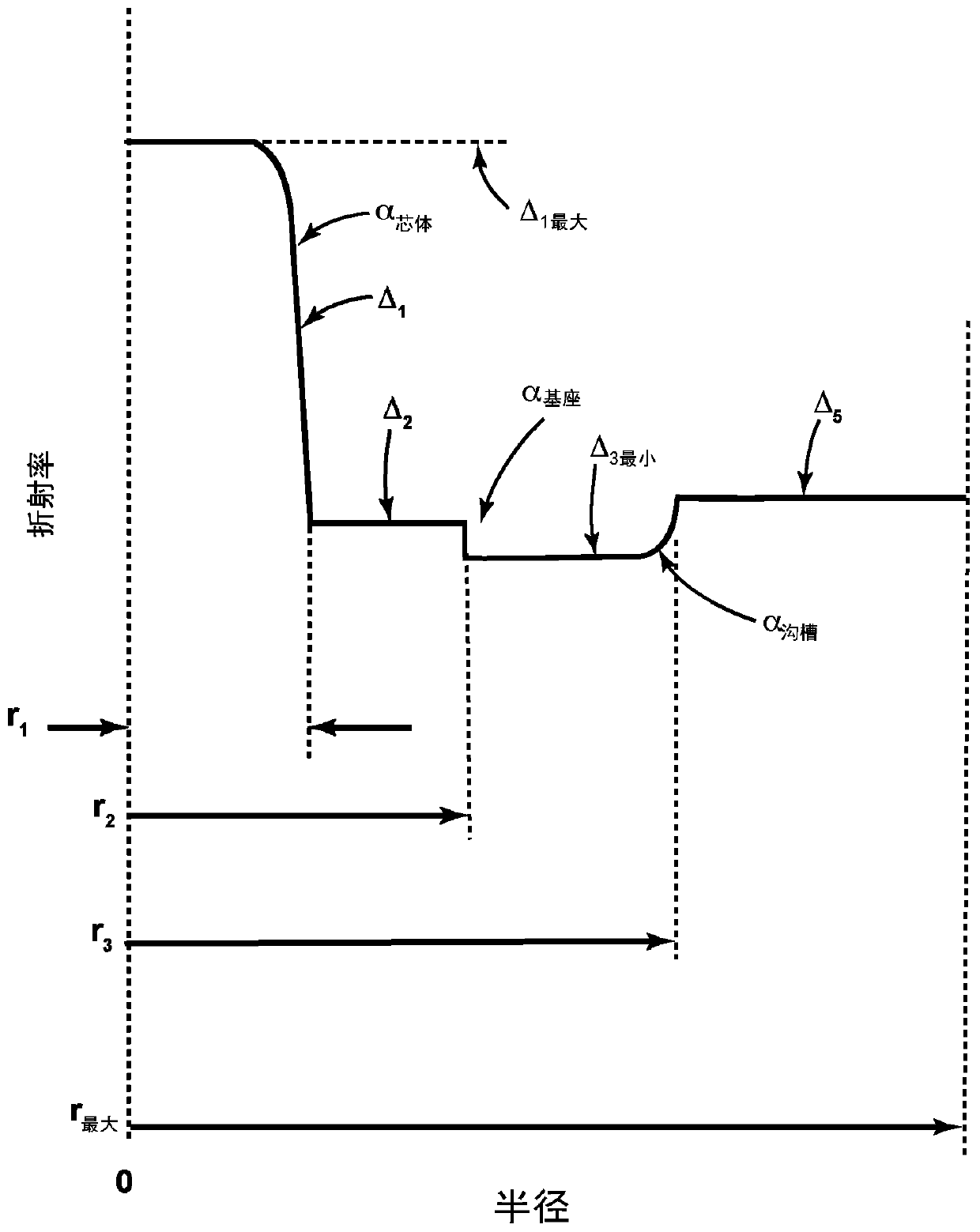

[0120] Embodiment A is a single-mode optical fiber comprising: (i) a chlorine-doped silica-based core comprising a core alpha (core α )≥4, radius r 1 and the maximum refractive index delta Δ 1最大 (ii) a cladding surrounding the core, said cladding comprising: a. a first inner cladding region adjacent to and in contact with the core and having a refractive index delta Δ 2 , radius r 2 and the minimum refractive index delta Δ 2最小 , so that Δ 2最小 1最大 and b. an outer cladding region surrounding the second inner cladding region and having a refractive index Δ 5 and radius r 最大 , so that Δ 2最小 ≥Δ 5 . The mode field diameter MFD of the optical fiber at 1310 is ≥ 9 microns, the cable cut-off is ≤ 1260 nm, and the zero dispersion wavelength range is 1300 nm ≤ λ 0 ≤1324nm, and for a 20mm mandrel, the macrobending loss at 1550nm is less than 0.75dB / turn.

[0121] The single-mode optical fiber of Embodiment A, further comprising a second inner cladding adjacent to and in contact ...

Embodiment approach B

[0130] Embodiment B is a single-mode optical fiber comprising: (i) a chlorine-doped silica-based core comprising a core alpha (core α )≥4, radius r 1 and the maximum refractive index delta Δ 1最大 (ii) a cladding surrounding the core, said cladding comprising: a. a first inner cladding region adjacent to and in contact with the core and having a refractive index delta Δ 2 , radius r 2 and the minimum refractive index delta Δ 2最小 , so that Δ 2最小 1最大 ; b. a second inner cladding adjacent to and in contact with the first inner cladding and having a refractive index Δ 3 , radius r 3 and the maximum refractive index delta Δ 3最大 , so that Δ 2最小 3最大 and c. an outer cladding region surrounding the second inner cladding region and having a refractive index Δ 5 and radius r 最大 , so that Δ 5 3最大 . The mode field diameter MFD of the optical fiber at 1310 is ≥ 9 microns, the cable cut-off is ≤ 1260 nm, and the zero dispersion wavelength range is 1300 nm ≤ λ 0 ≤1324nm, and for a 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer radius | aaaaa | aaaaa |

| Outer radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com