Steel fiber pull-out test piece pouring mold, pouring method and bond slip test method

A technology for casting molds and steel fibers, which is applied in the fields of casting molds, pouring and bonding slip testing for steel fiber pull-out specimens, can solve the problems of small pull-out load, measurement errors affecting the accuracy of test results, etc., and achieves easy removal. Mold, save production time, and operate with high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

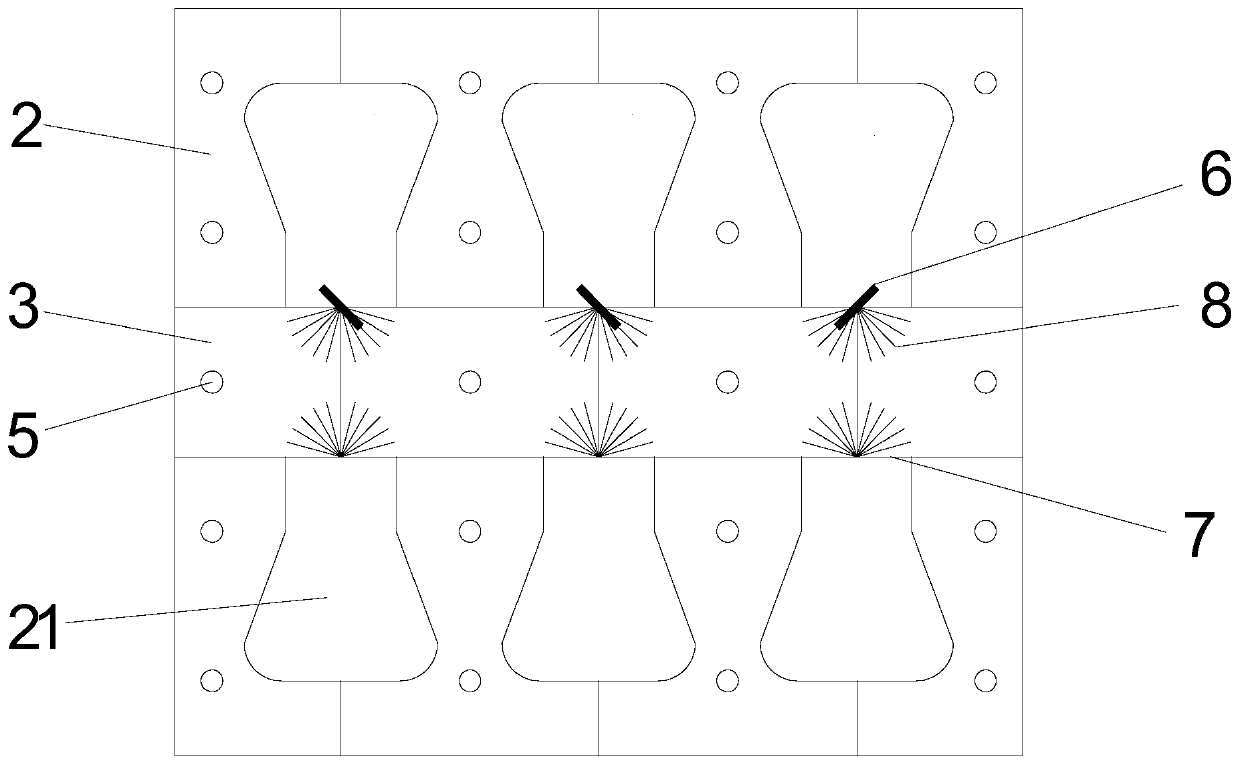

[0082] The pouring material is ultra-high performance concrete.

[0083] Steel fiber type: 0.3mm in diameter, 25mm in length, hook-shaped at the end.

[0084] Steel fiber angle: 0 degrees.

[0085] Steel fiber buried depth: 5mm and 10mm.

[0086] PTFE slice size: thickness 0.2mm, length 30mm, width 14mm.

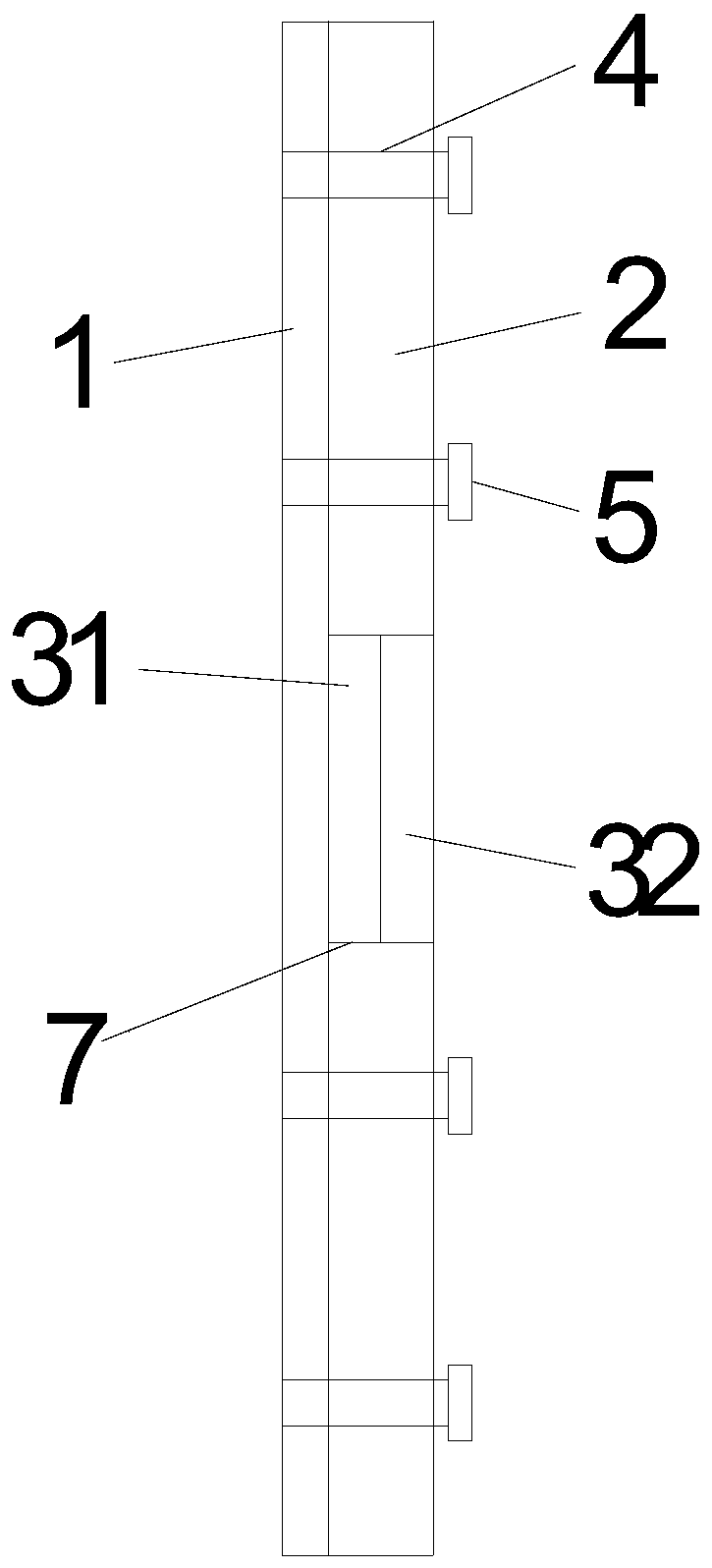

[0087] Bottom plate 1 size: length 230mm, width 200mm, thickness 6mm. There are 4 rows of bolt holes 5 on the bottom plate 1, the center of the first row of bolt holes 5 is 20mm away from the end of the bottom plate 1, the distance between the second row of bolt holes 5 and the first row of bolt holes 5 is 40mm, the third and fourth row of bolt holes 5 The first and second rows of bolt holes 5 are arranged symmetrically with respect to the central axis in the length direction of the bottom plate 1 . The diameter of the bolt holes 5 is 3 mm, and the distance between adjacent bolt holes 5 is 70 mm.

[0088] Dimensions of the top plate 2: length 230mm, width 80mm, thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com