Heliostat plate support

A heliostat and mirror plate technology, applied in the field of solar power generation, can solve the problems of affecting tower solar power generation efficiency, large overall structural error, unstable reflected light waves, etc., and achieve the effect of increasing strength, easy replacement, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the description of the drawings.

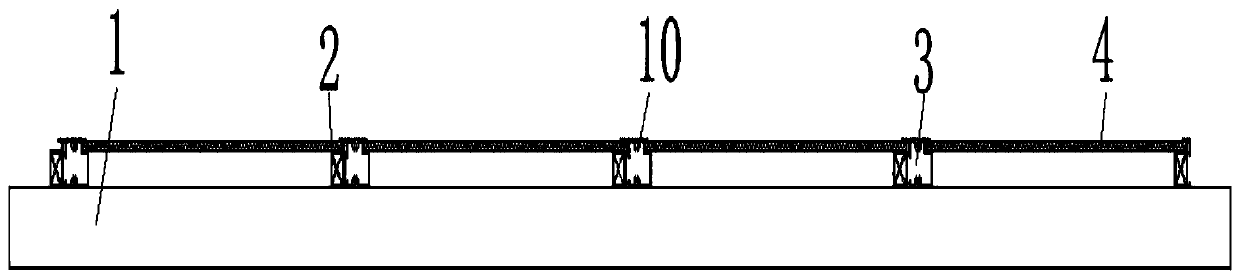

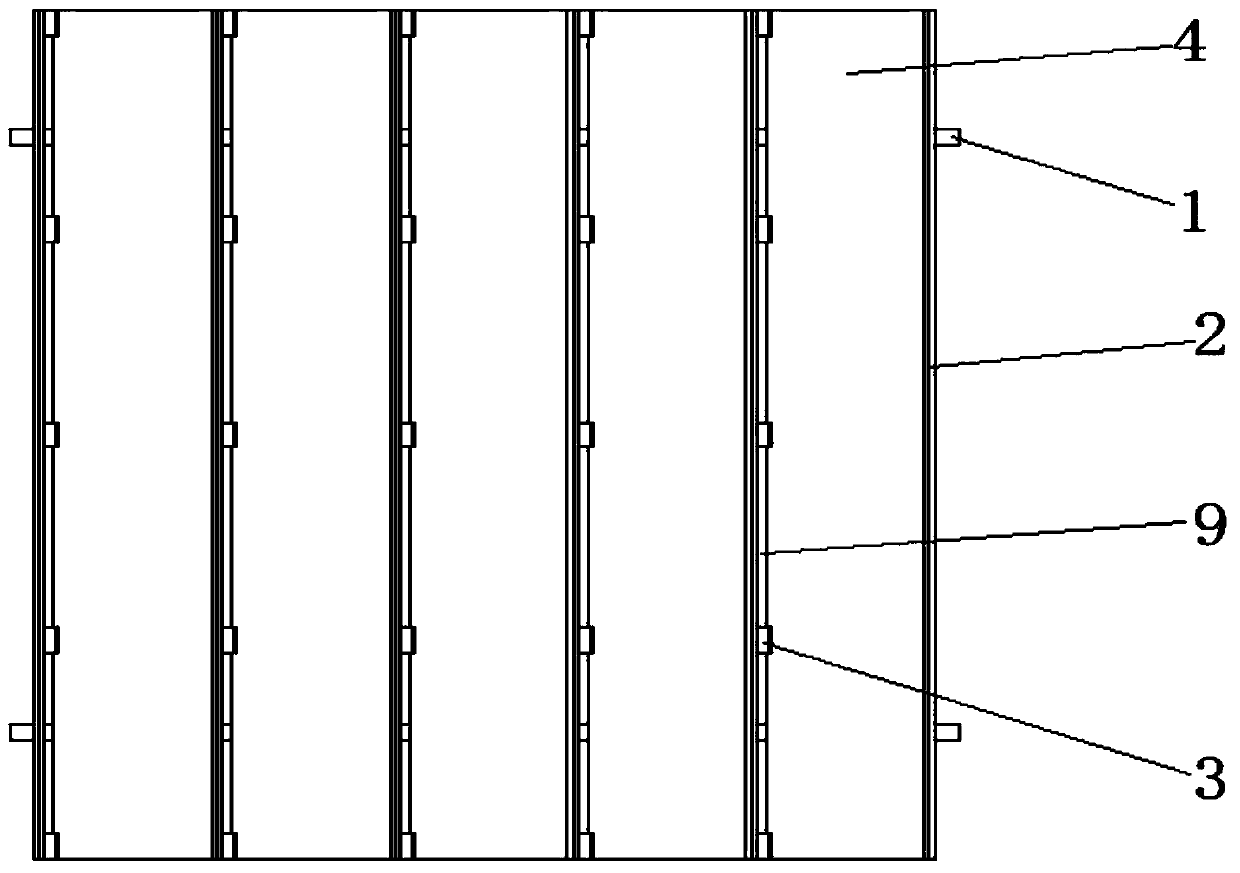

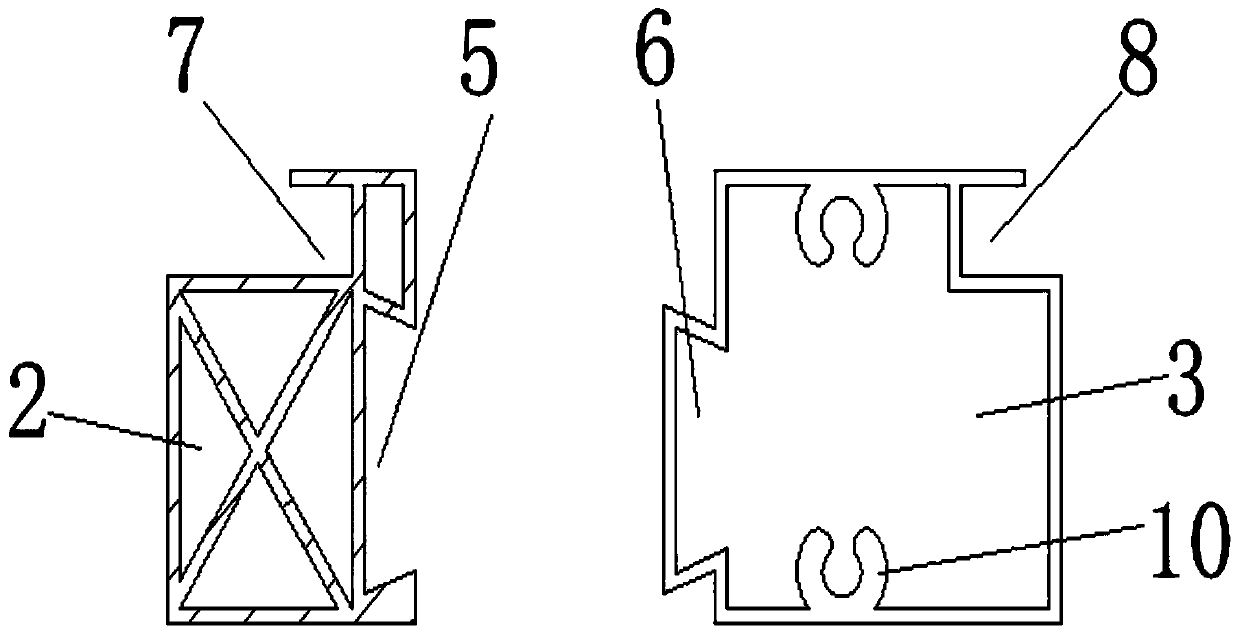

[0020] Such as figure 1 , 2 A heliostat mirror plate bracket shown in, 3, and 4 includes a main beam 1, a secondary beam 2, a mirror bracket 3, and a mirror 4. The main beam 1 is provided with two, and the main beam 1 is arranged separately in parallel, Take the sub-beam 2 and use a polymer adhesive to bond its two ends to the upper surface of the two main beams 1 vertically, and bond the required sub-beams 2 at even intervals according to the above steps. At the same time, the opening directions of the dovetail groove 5 on the secondary beam 2 are all facing one side; a dovetail groove 5 is provided on the upper side of the secondary beam 2, and a dovetail 6 is provided on the side of the mirror bracket 3, and the mirror bracket 3 The dovetail 6 is aligned with the dovetail groove 5 of the secondary beam 2 and inserted in sequence. After insertion, the reflector br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com